Stereo garage lifting vehicle carrying flat plate safety state monitoring and evaluating method

A three-dimensional garage, safe state technology, applied in the direction of measuring devices, buildings where cars are parked, force/torque/power measuring instruments, etc., can solve the problem of uneven deformation of four steel wire ropes, bearing capacity, no relevant reports, rollover or hanging collision Accidents and other problems, to avoid the effect of hook failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

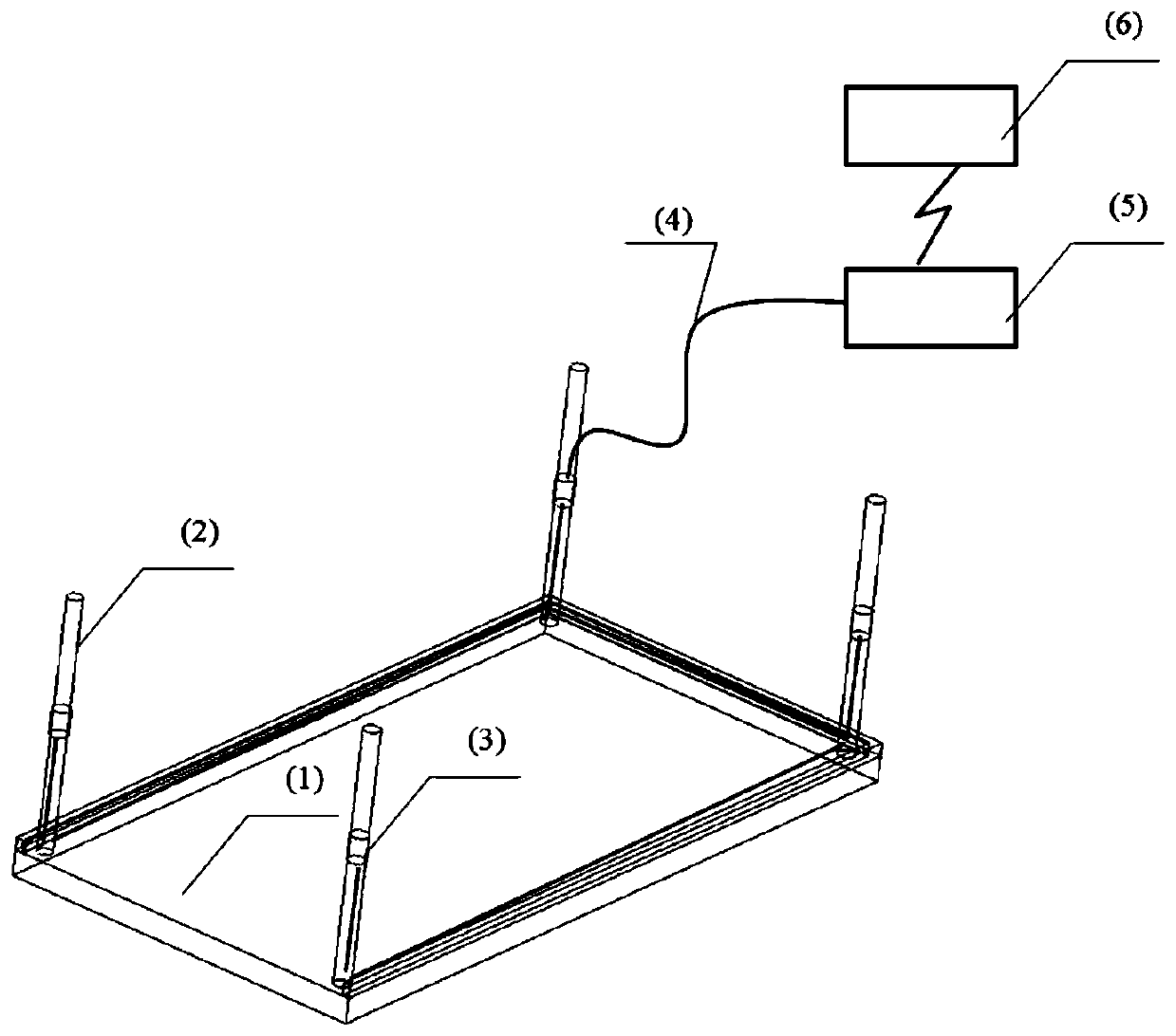

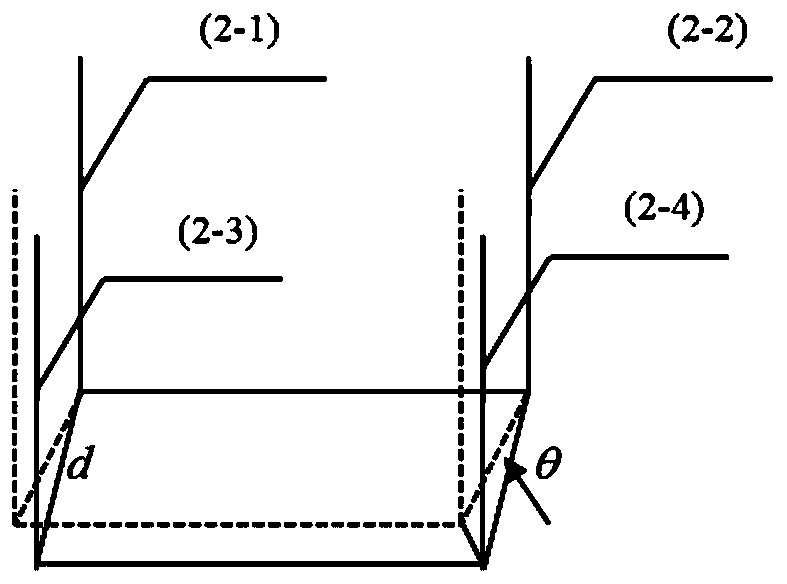

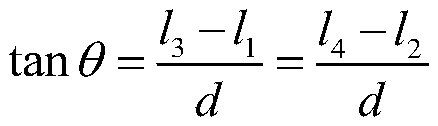

[0014] attached figure 1 It is a structural schematic diagram of a method for monitoring and evaluating the safety state of a three-dimensional garage lifting vehicle-carrying platform of the present invention. The specific embodiment is that four temperature self-compensating fiber grating strain sensors 3 are mechanically fixedly installed on the four steel wire ropes 2 of the lifting vehicle platform 1, and the temperature self-compensating fiber grating strain sensors 3 and the steel wire ropes 2 deform cooperatively. Four temperature self-compensating fiber grating strain sensors 3 are connected end to end to form a fiber optic path and are connected to the fiber grating data acquisition unit 5 through the fiber transmission line 4 . The fiber grating data acquisition unit 5 collects the strain data of the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com