Fault diagnosis method, system and device for permanent magnet synchronous motor as well as readable medium

A technology for permanent magnet synchronous motors and diagnostic methods, which is applied in the field of systems and devices, readable media, and fault diagnosis methods for permanent magnet synchronous motors, and can solve problems such as poor fault diagnosis performance, complex implementation, and high requirements for controller computing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065]Some of the existing fault diagnosis methods cannot separate the fault of the current sensor and the fault of the rotor position sensor, some of them are complicated to implement and require high computing power of the controller, and some of them need to obtain the information of the whole vehicle and other components, so as to make the fault diagnosis. Poor performance.

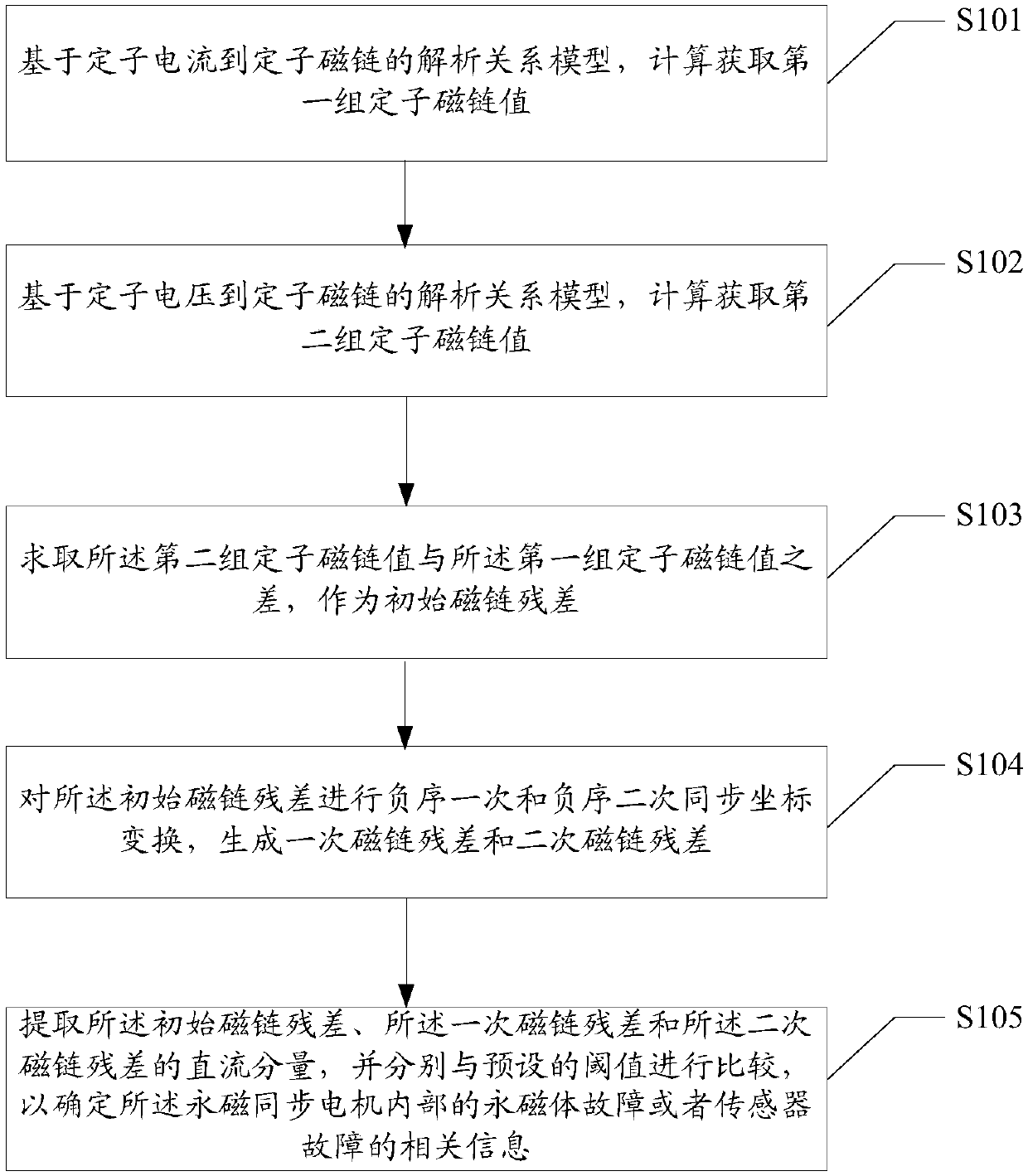

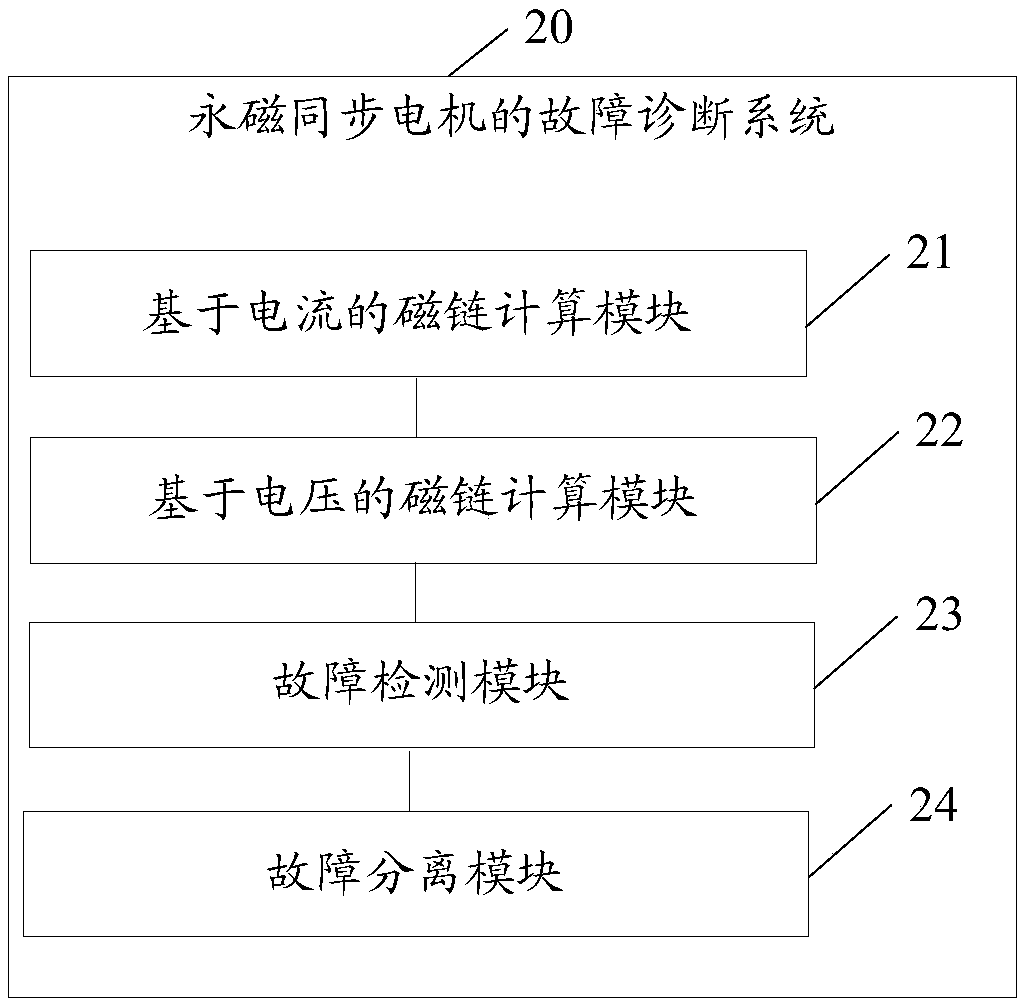

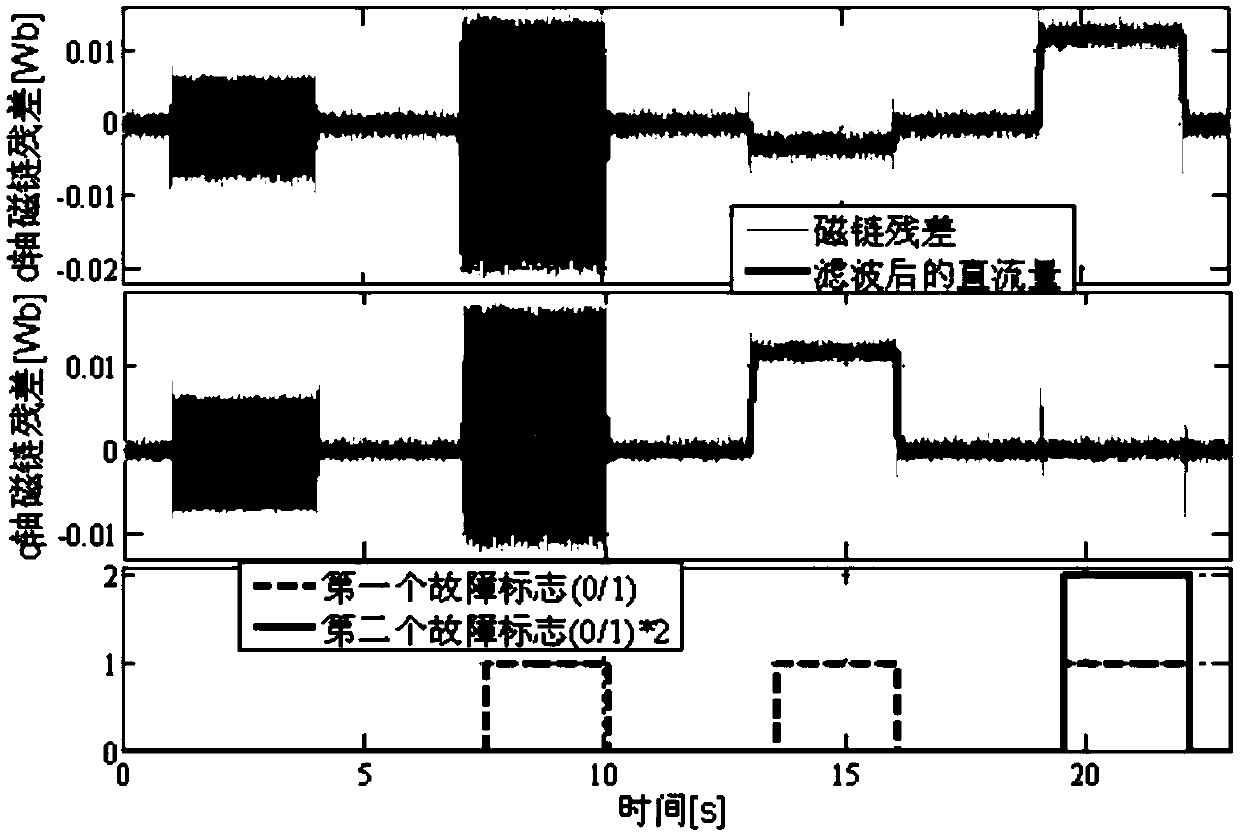

[0066] In the embodiment of the present invention, the first set of stator flux linkage values and the second set of stator flux linkage values are obtained by calculation, and then the difference between the second set of stator flux linkage values and the first set of stator flux linkage values is obtained as the initial value The flux linkage residual, and the negative-sequence primary and negative-sequence secondary synchronous coordinate transformations are performed on the initial flux linkage residual to generate the primary flux linkage residual and the secondary flux linkage residual, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com