A Method for Improving Vibration Consistency of Linear Motors

A linear motor and consistent technology, applied in the direction of motor generator testing, AC motor control, force/torque/power measuring instrument, etc., can solve the problems of rising motor manufacturing cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] Below in conjunction with accompanying drawing, do further example description for the present invention:

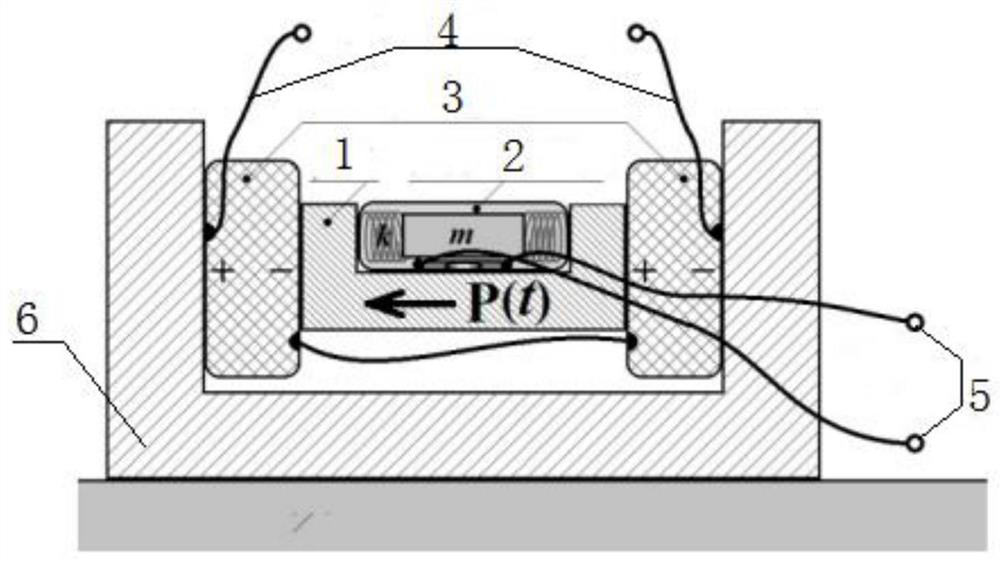

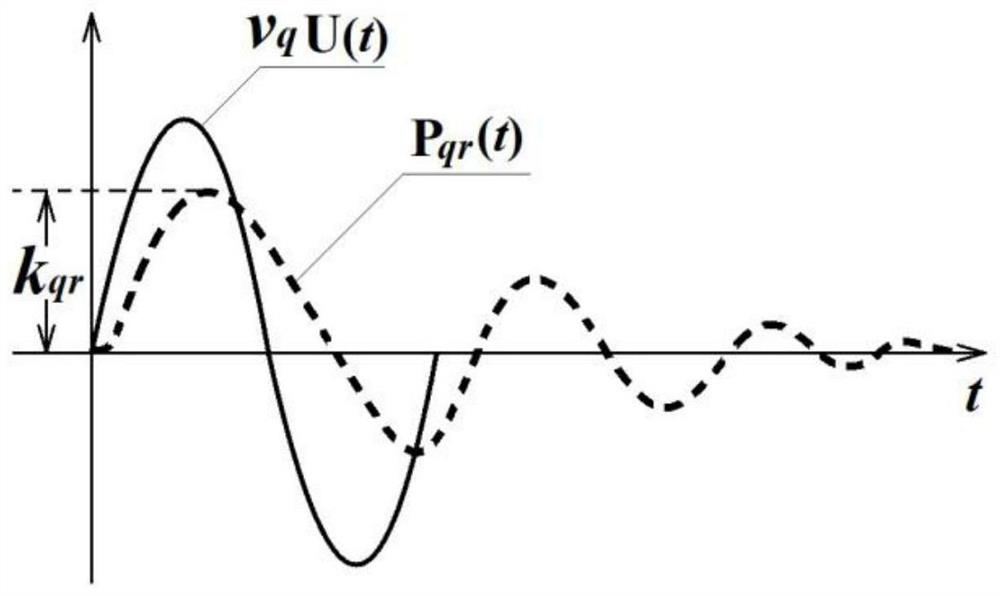

[0105] The invention involves two parts, one is a precise driving method for a linear motor based on driving parameters, and the other is a testing method for driving parameters of motor products. A method for improving the vibration consistency of a linear motor, characterized in that the drive signal is constructed with its accurate resonance frequency F0 and drive parameters when the motor is working;

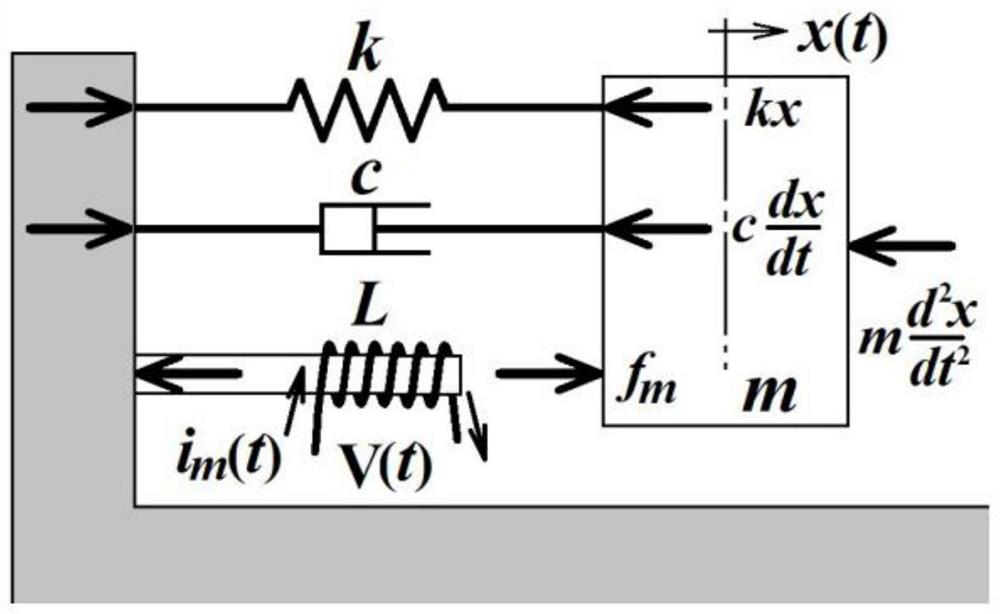

[0106] The driving signal refers to the electrical signal applied to the motor input to drive the motor to vibrate, such as figure 1 V(t) shown in. The drive signal that the present invention adopts comprises two types:

[0107] (1) Sinusoidal signal: shaped like a function sinusoidal alternating voltage. in:

[0108] V m is the signal voltage amplitude;

[0109] f 0 is the signal frequency;

[0110] is the initial phase angle, since the variable t i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com