Precision etching device for flexible circuit board

A technology of flexible circuit boards and etching devices, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of increasingly high etching process requirements, difficult etching of circuit boards, and the inability of thin plates to pass through, so as to reduce the pool effect , Etching uniformity improvement, the effect of improving etching uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

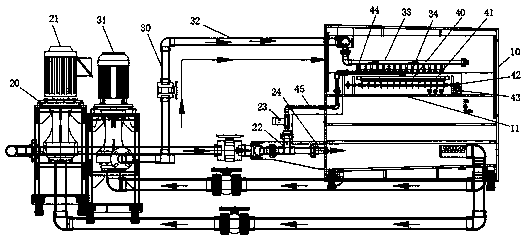

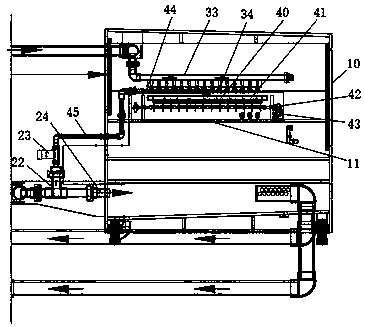

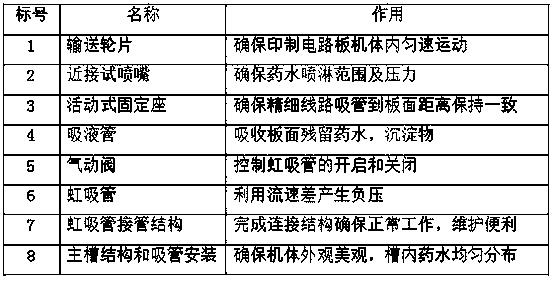

[0013] like figure 1 As shown, a precision etching device for a flexible circuit board includes a main groove 10, a siphon part 20, a spray part 30 and a liquid suction part 40. 21 connection, one end is connected to the liquid suction part 40 through the liquid suction connection hose 44, the liquid suction part 40 includes a liquid suction tube 41, and the liquid suction tube 41 is made of titanium material, which has high strength and long service life. And the advantages of not easy to deform. The suction pipe 41 is connected to the siphon pipe 22 through a liquid suction connection hose 44, the spray part 30 includes an upper main spray pipe 32, and one end of the upper main spray pipe 32 is connected to the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com