Manufacturing method for fine circuit

A production method and technology of fine lines, which are applied in the manufacture of printed circuits, printed circuits, electrical components, etc., can solve the problems of large pool effect, affect the accuracy of lines, increase the amount of side erosion, etc., to accelerate the exchange, improve the exchange speed, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

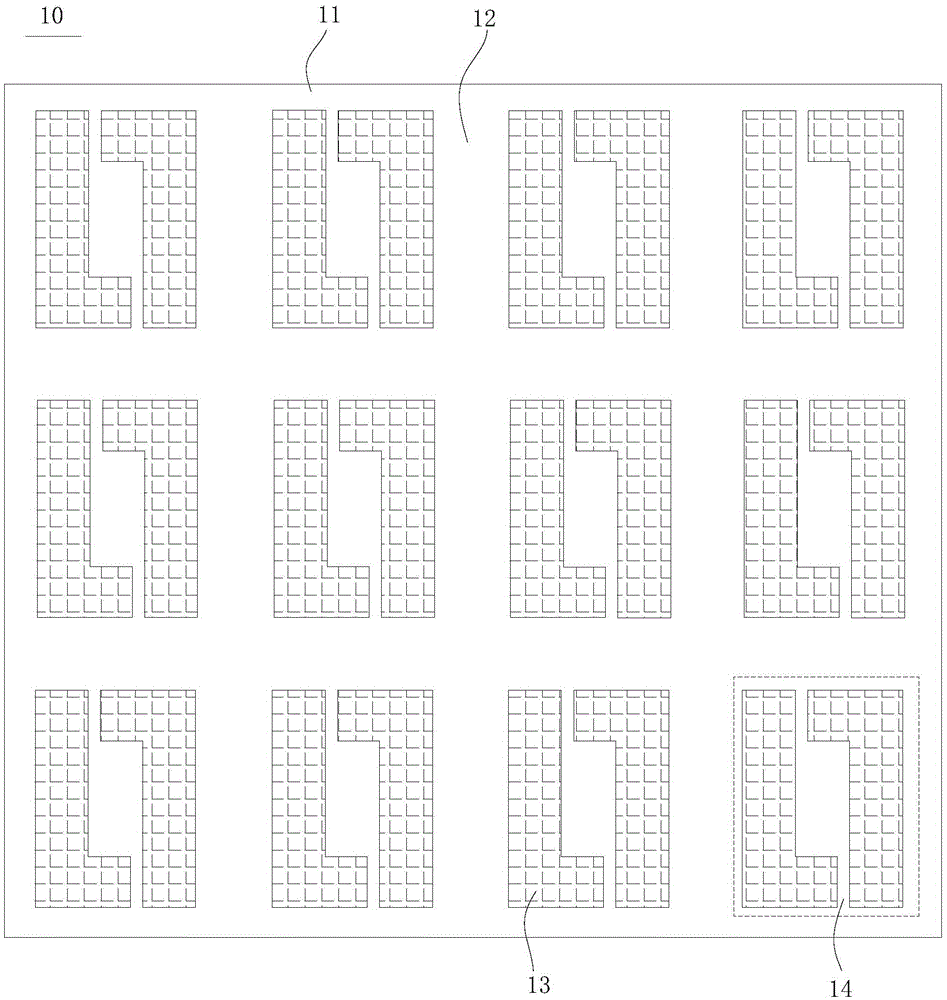

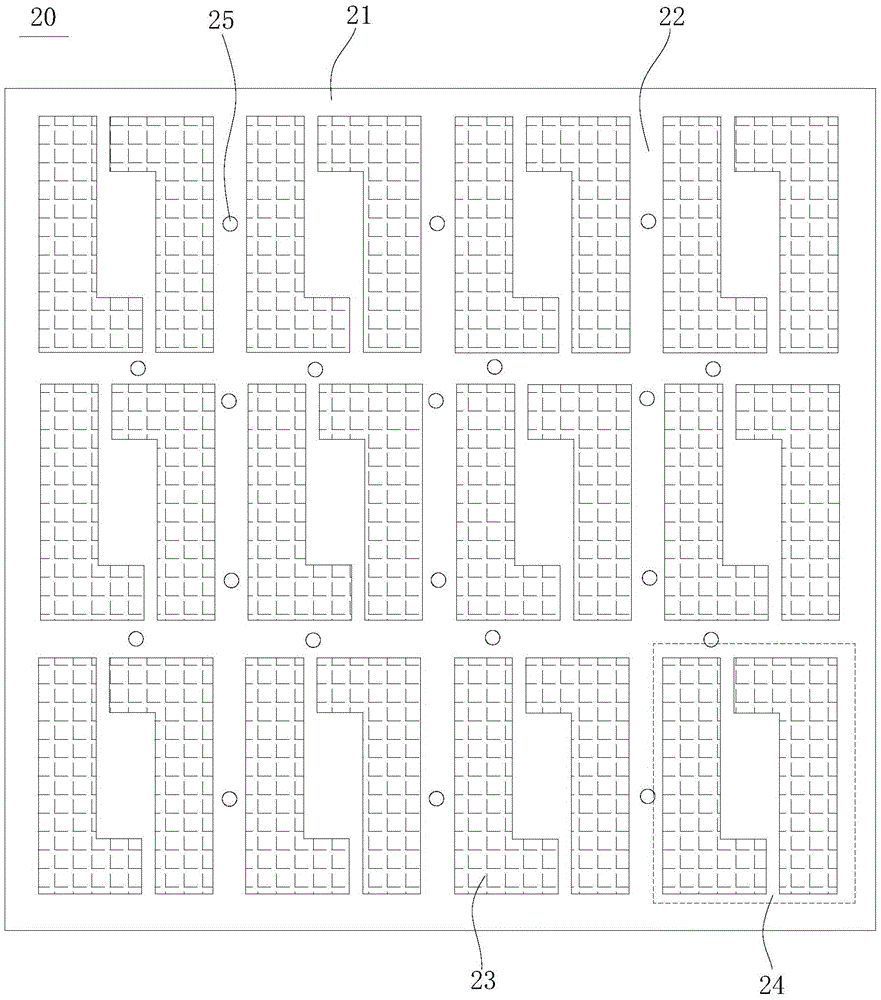

[0020] This embodiment provides a method for manufacturing a fine circuit, which can reduce the pool effect during etching of the outer layer and improve the etching capability.

[0021] The specific production steps are as follows:

[0022] (1) multilayer board

[0023] According to the existing technology, the inner layer circuit (forming the core board) is sequentially processed through cutting → negative film process → pressing, and the base material is made into an undrilled multi-layer board, that is, the inner layer core board, the prepreg and the outer layer of copper Foils are pressed together to form a board; the prepared multi-layer board includes a plurality of module areas, and the module area includes a plurality of areas for forming unit boards, which are called unit board areas. A molding edge with a width of 3.0mm for post-molding is left between each module area (in other embodiments, the width of the molding edge can be determined according to the layout de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com