Method for manufacturing mildewproof sheet and packaging material

A manufacturing method and technology of packaging materials, which are applied in the directions of transportation and packaging, packaging, wrapping paper, etc., can solve the problems of damaged commodity value, moldy clothing and articles without mold prevention, etc., and achieve the effect of low cost and mildew inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] First, 30 g of an antifungal agent (Sanjin Co., Ltd. SAN-N-DS (organic antibacterial agent) manufactured by Printing Co., Ltd.) was prepared to prepare a printing ink containing 2.9% by mass of an antifungal agent. In addition, as a substrate sheet, a polyethylene film (HDPE) of 1000 cm x 3000 m was prepared.

[0070] Next, the above-mentioned printing ink was set on a gravure printing machine, and the above-mentioned substrate sheet was subjected to full-surface solid printing with a part of hollow characters ("Anti-mold MADE IN JAPAN"). In addition, the depth (plate depth) of the recessed part of the plate cylinder (gravure plate) installed in the gravure printing machine was 18 micrometers. Operate as above to make anti-mildew sheets. In addition, the total area of the printing area obtained by using the printing ink was 98% of the whole area of a base material sheet.

Embodiment 2

[0087] [Example 2, Comparative Example 2]

[0088] First, 30 g of an antifungal agent (manufactured by Sanjinsha Printing Co., Ltd., SAN- N-DS (organic antibacterial agent)) prepared a printing ink containing 2.9% by mass of an antifungal agent. Moreover, the polyethylene film (LDPE) of 50 mm x 50 mm x 0.02 mm (thickness) was prepared as a base material sheet.

[0089] Next, the above-mentioned printing ink was placed on a gravure printing machine, and the above-mentioned substrate sheet was subjected to full-face solid printing with a part of hollow characters ("Anti-mold MADE IN JAPAN"). In addition, the depth of the recessed part of the plate cylinder (gravure plate) provided in the gravure printing machine was 20 micrometers. Operate as above to make anti-mildew sheets. In addition, the total area of the printing area obtained by using the printing ink was 98% of the whole area of a base material sheet.

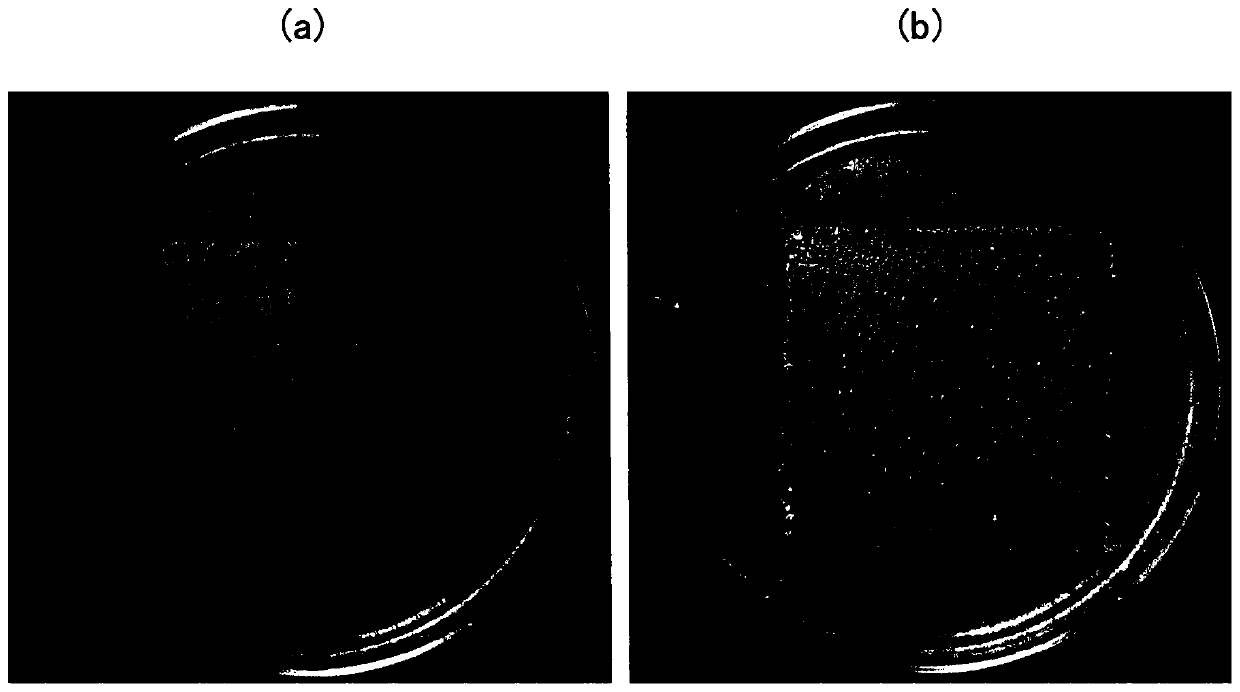

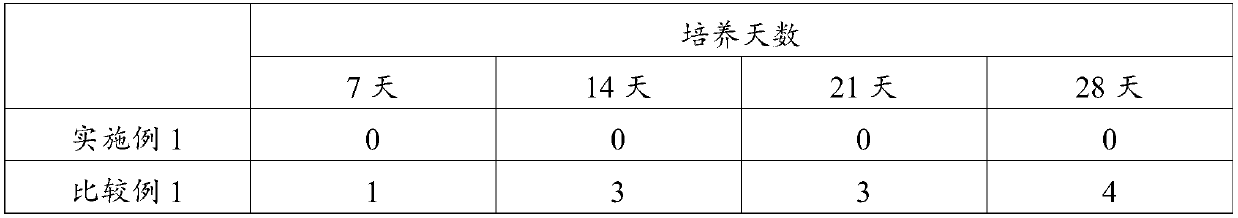

[0090] The evaluation test was performed in accordance with ...

Embodiment 3

[0095] First, 30 g of an antifungal agent (manufactured by Sanjinsha Printing Co., Ltd., SAN- N-DS (organic antibacterial agent)) prepared a printing ink containing 2.9% by mass of an antifungal agent. Moreover, the polyethylene film (LDPE) of 100 mm x 100 mm x 0.03 mm (thickness) was prepared as a base material sheet.

[0096]Next, the above-mentioned printing ink was set on a gravure printing machine, and the above-mentioned base material sheet was printed in the same manner as in Example 1. Among them, a plate cylinder (gravure plate) installed on a gravure printing machine used a gravure plate having a depth of recesses (plate depth) of 20 μm. Operate as above to make anti-mildew sheets. In addition, the total area of the printing area obtained by using the printing ink was 98% of the whole area of a base material sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com