Multi-row brassica juncea combine harvester

A technology for combine harvesters and cabbage heads, which is applied to digging harvesters, harvesters, topping machines, etc., can solve the problem of inability to achieve cutting height, difficulty in ensuring the quality of cut roots, and failure to properly solve the problem of root cutting and transportation of cabbage heads. Stem and leaf cutting and tumor-like stem separation, etc., to avoid cutting area and reduce cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

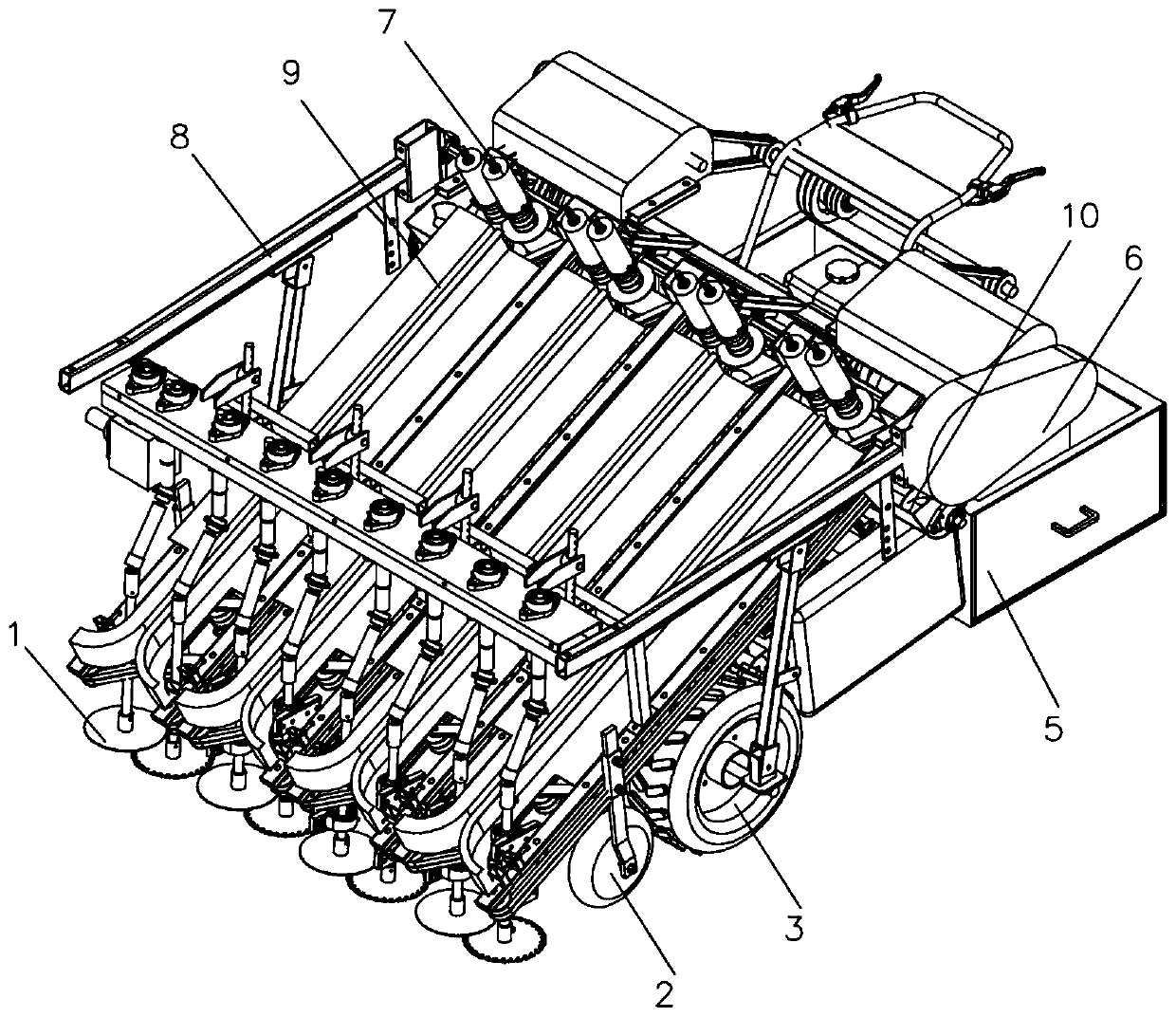

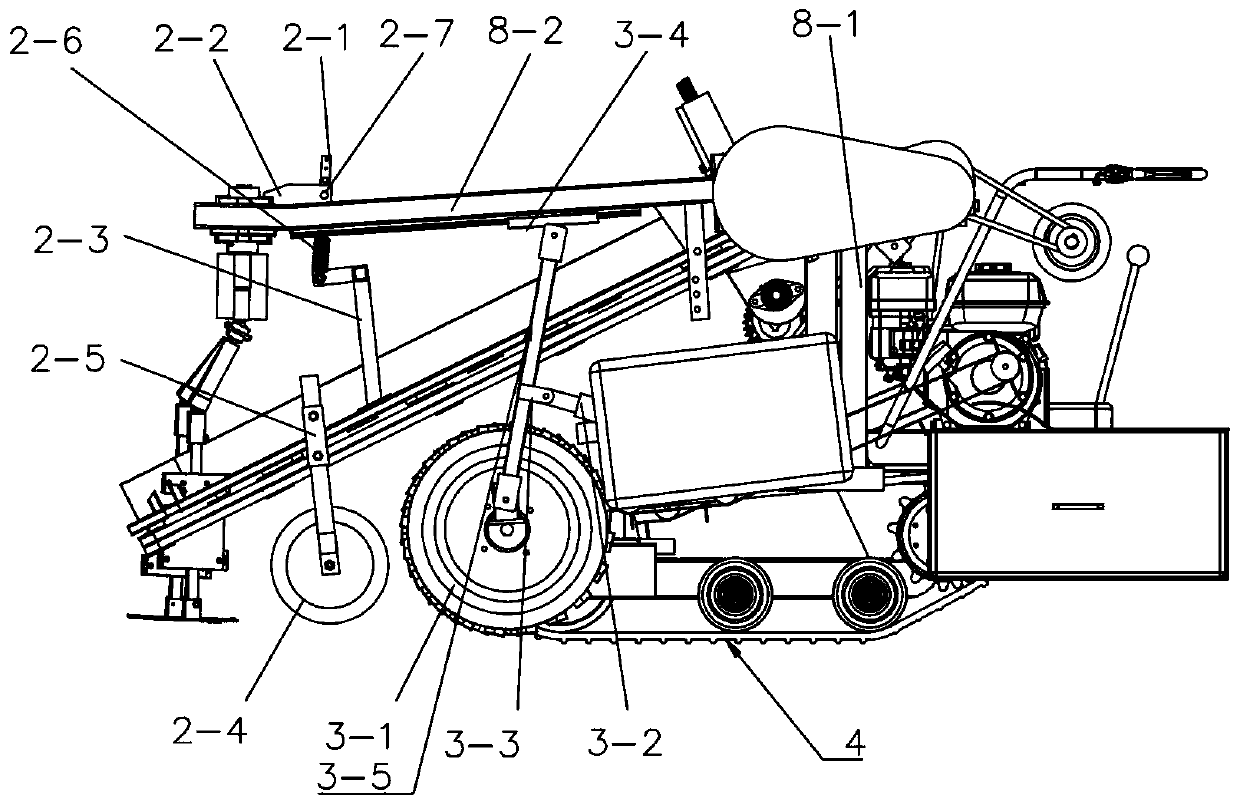

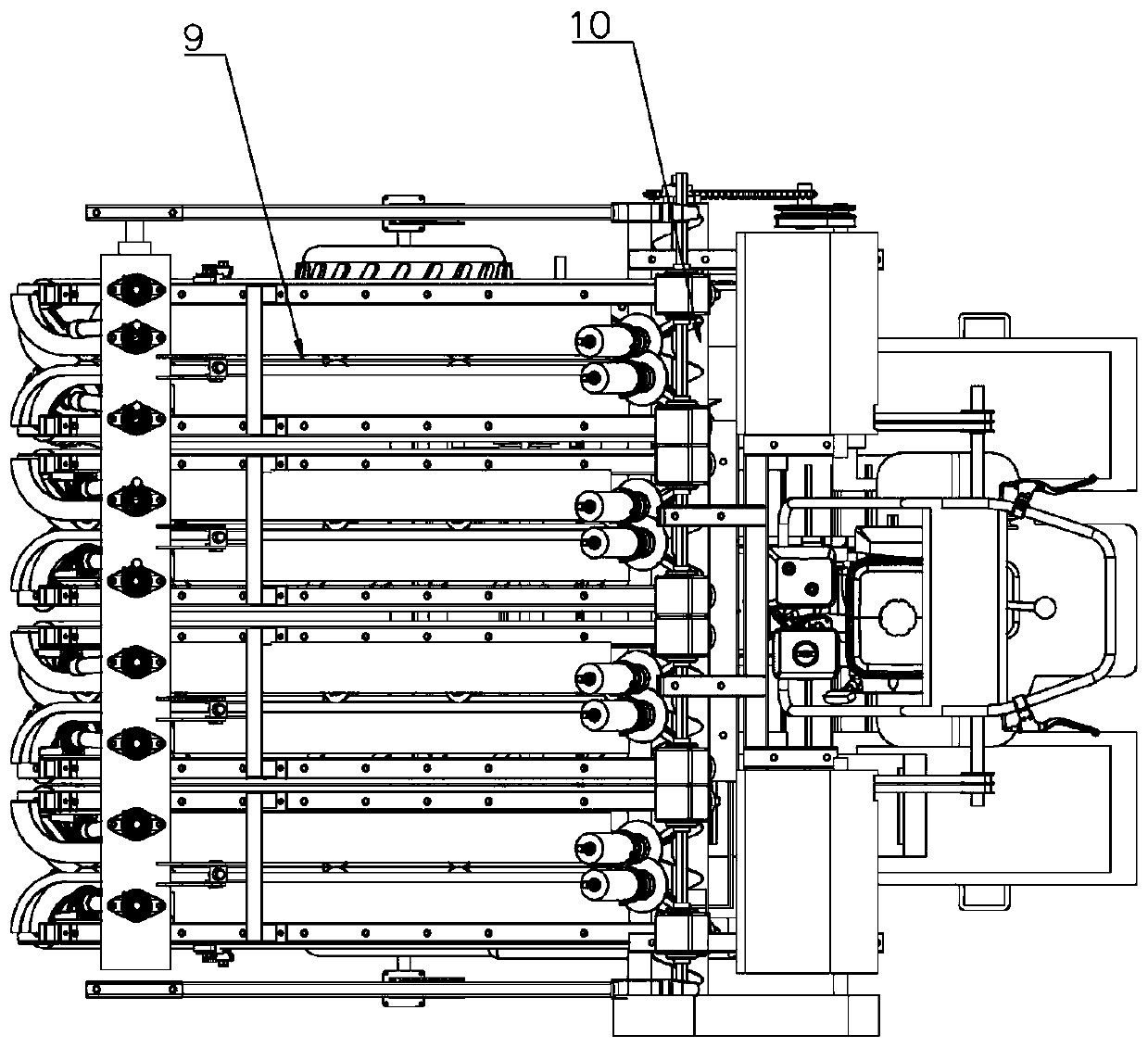

[0034] This embodiment is a four-row cabbage head multi-row combine harvester, which includes a frame 8 and a power transmission mechanism 6 placed on the crawler chassis 4. The front end and the rear end of the leaf lifting conveying mechanism 9 are equipped with a root cutting mechanism 1 and a leaf cutting mechanism 7 respectively; Supported by the height adjustment mechanism 3, the leaf cutting mechanism 7 is connected to the leaf removing mechanism 10 of the output end receiving the collecting device 5 under the leaf cutting mechanism 7.

[0035] See the specific structure Figure 1 to Figure 3 , the frame 8 on the crawler chassis 4 has a column 8-1 and a forward arm 8-2, the upper part of the column 8-1 is hinged to support the rear end of the clip blade lifting conveying mechanism 9, and the front end of the forward arm 8-2 is passed through the profiling The adjustment mechanism 2 is connected to the middle part of the clip blade lifting and conveying mechanism 9, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com