Steam generator water supplement control system and method and cooking device

A technology of a steam generator and a control system, which is applied to steam cooking utensils, cooking utensils, roasters/barbecue grids, etc., can solve problems such as affecting the health of users, poor user experience, affecting the cooking effect of ingredients, etc., and save water. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

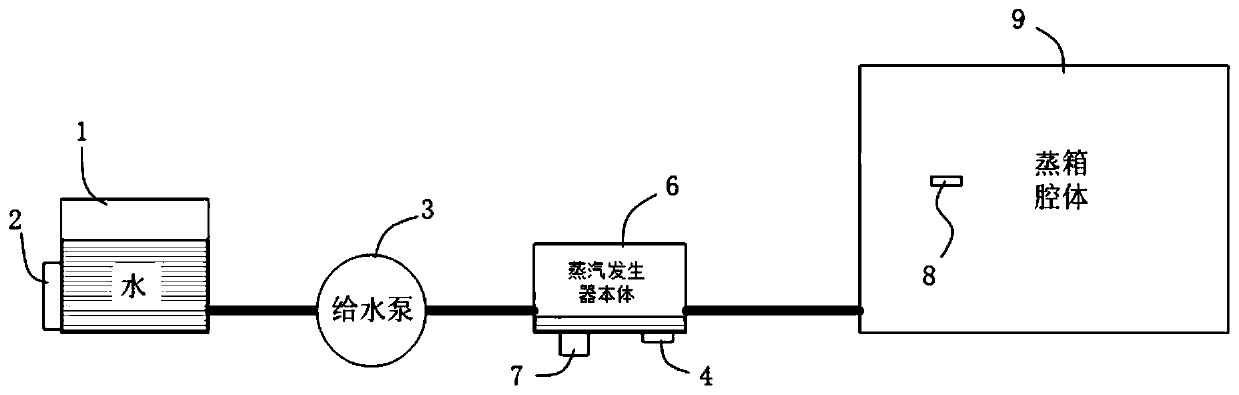

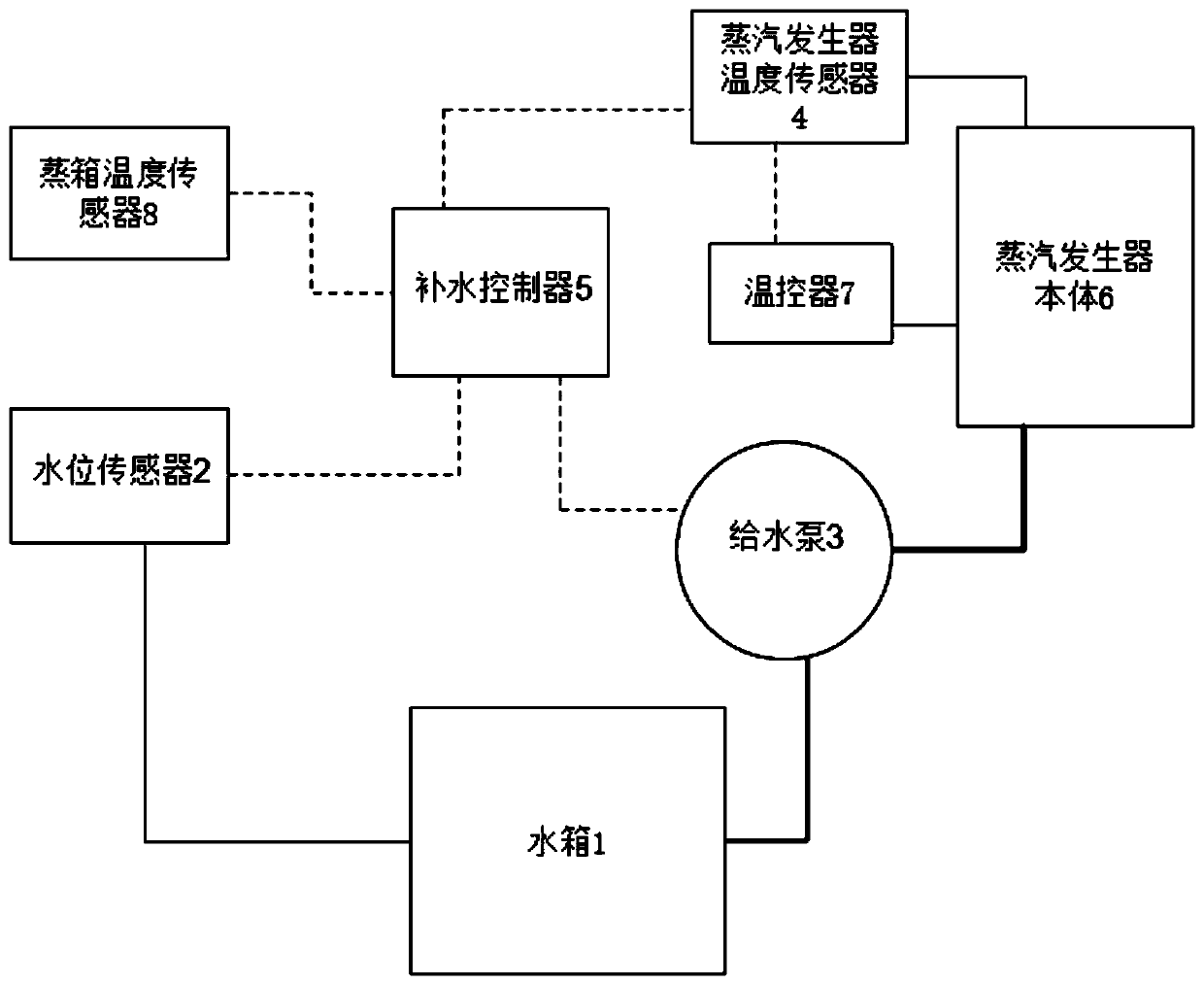

[0026] Embodiment 1 of the present invention provides a steam generator replenishment control system, such as figure 1 and 2 As shown, it includes a water tank 1, a water level detection unit, a feed water pump 3, a steam generator temperature detection unit, a replenishment controller 5 and a steam generator body 6; in this embodiment, the water level detection unit is preferably a water level sensor 2, a steam generator The temperature detection unit is preferably a steam generator temperature sensor; the water level sensor 2 is fixed on the water tank 1; the feed water pump 3 is connected between the water tank 1 and the steam generator body 6 through a water pipe; the steam generator temperature sensor 4 is fixed on the steam generator body 6 ; the water level sensor 2 , the feedwater pump 3 and the steam generator temperature sensor 4 are all electrically connected to the water supply controller 5 .

[0027] With the above structure, the steam generator body 6 is detecte...

Embodiment 2

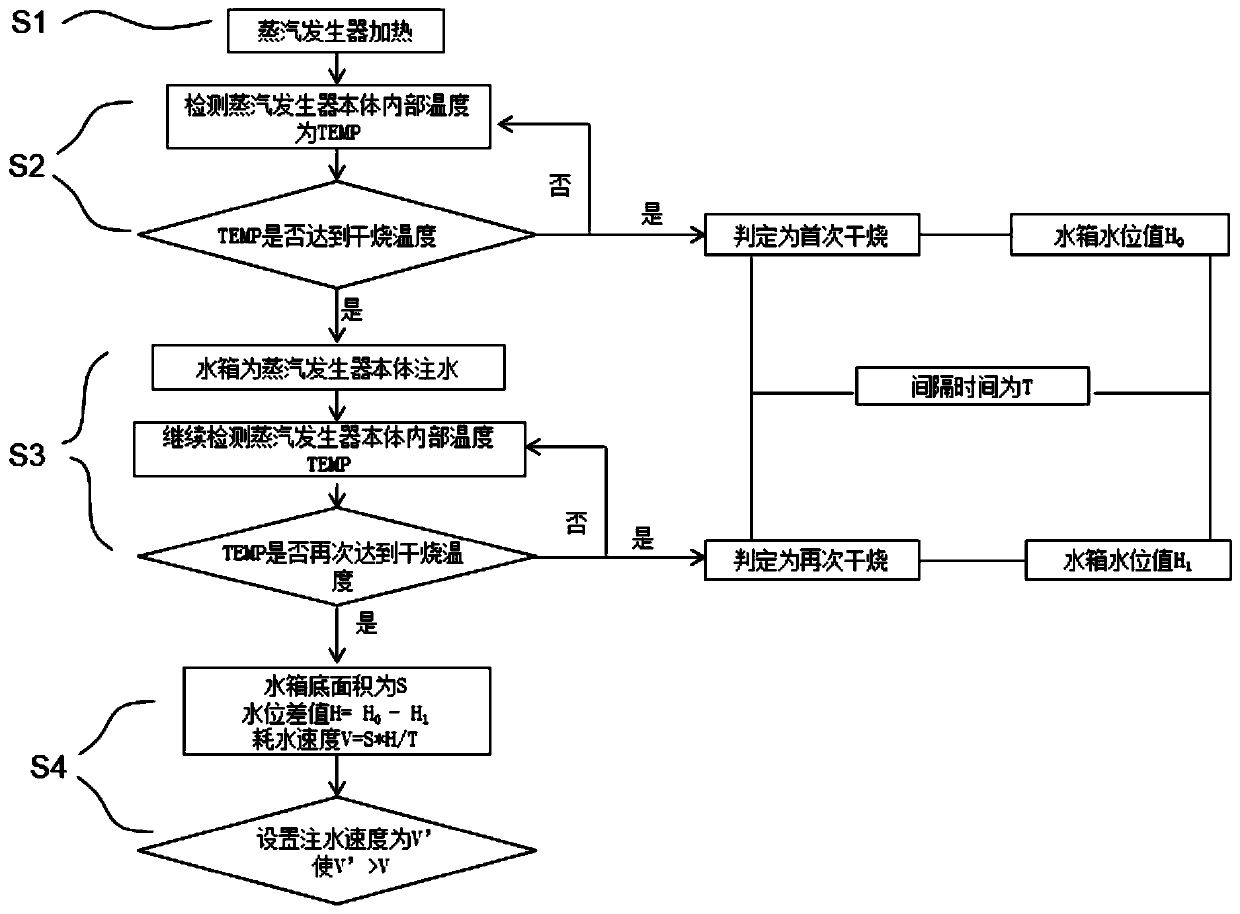

[0031] Embodiment 2 of the present invention provides a steam generator replenishment control method, which is used in the steam generator replenishment control system in Embodiment 1, such as image 3 and 4 shown, including the following steps:

[0032] S1, the steam generator works;

[0033] S2, the steam generator temperature sensor 4 detects the internal temperature of the steam generator body 6, and when the internal temperature reaches the set dry-burning temperature value, it is determined that the steam generator body 6 is dry-burning for the first time, and enters step S3; otherwise, continue to detect the internal temperature;

[0034] S3, the water tank 1 injects water into the steam generator body 6, the steam generator continues to heat, the steam generator temperature sensor 4 detects the internal temperature of the steam generator body 6 again, and when the internal temperature reaches the set dry burning temperature value again, it is judged The steam generat...

Embodiment 3

[0043] Embodiment 3 of the present invention also provides a cooking device, including a cooking device body and the steam generator water replenishment control system in Embodiment 1. The steam generator water replenishment control system is located inside the cooking device body.

[0044] The cooking device in the third embodiment includes, but is not limited to, a steamer, an integrated steamer and oven, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com