Engine cylinder cover

A technology for engine cylinders and cylinder heads, which is applied in the direction of engine components, machines/engines, cylinder heads, etc., can solve the problems that the forced cooling effect cannot be guaranteed, and achieve the effect of improving the cooling effect, good manufacturing process, and uniform wall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

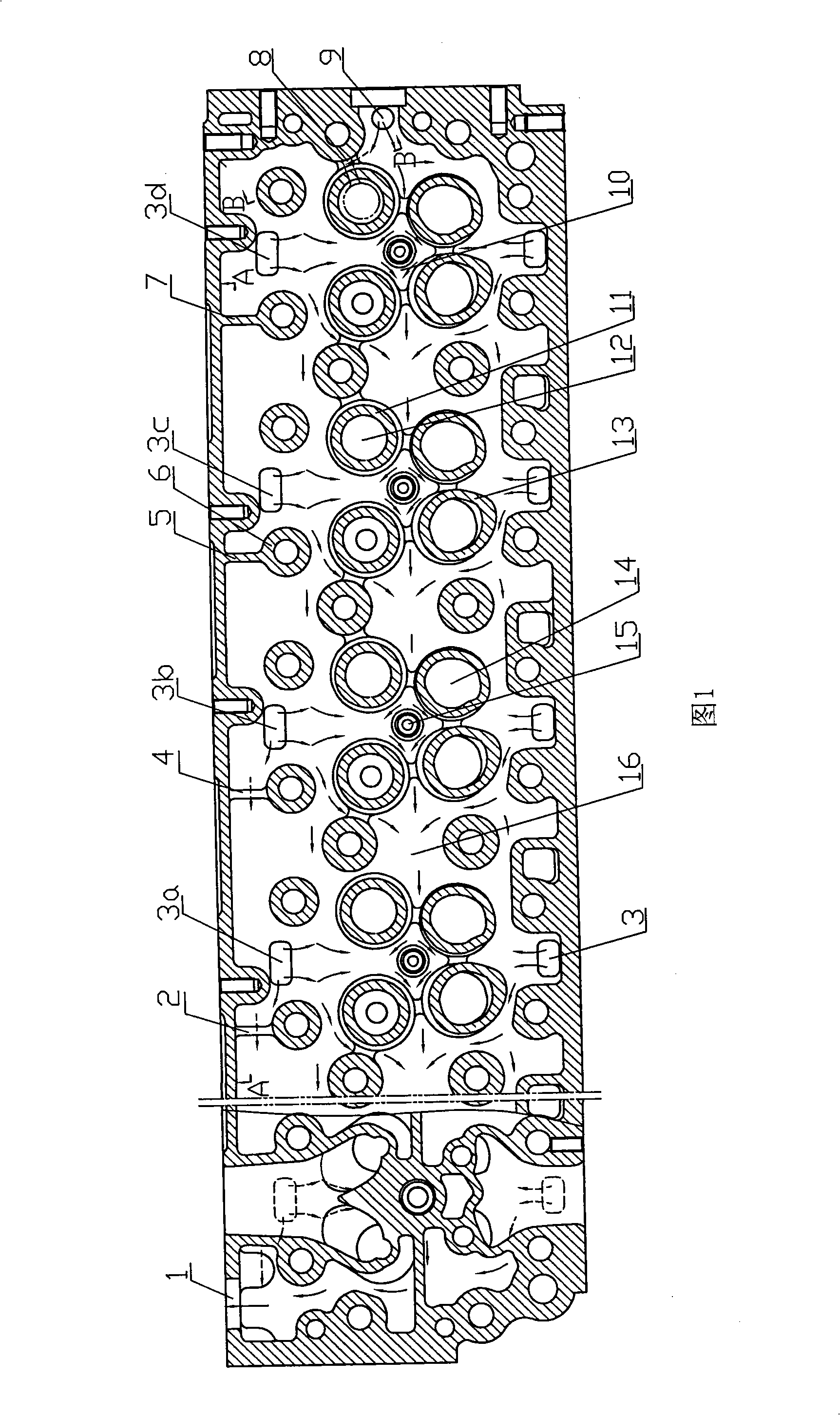

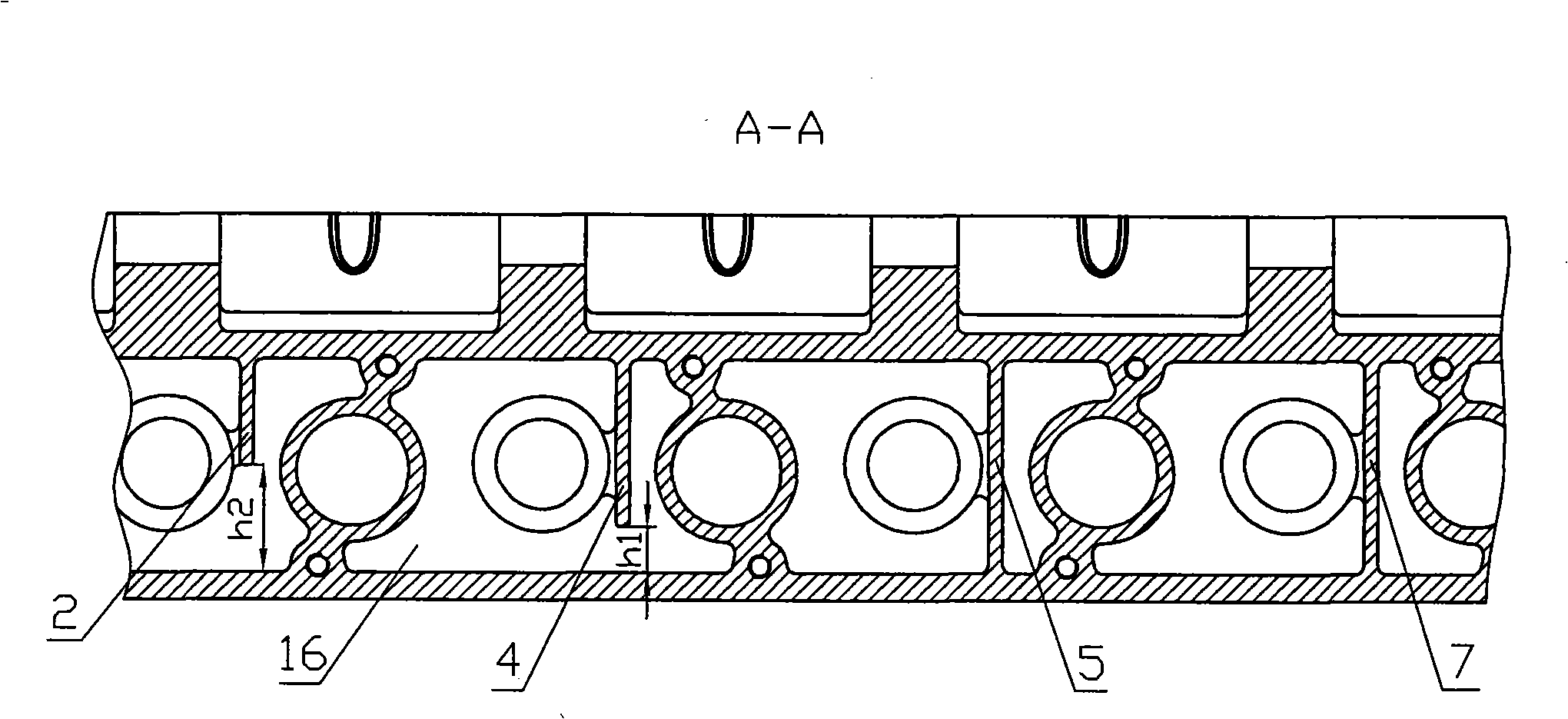

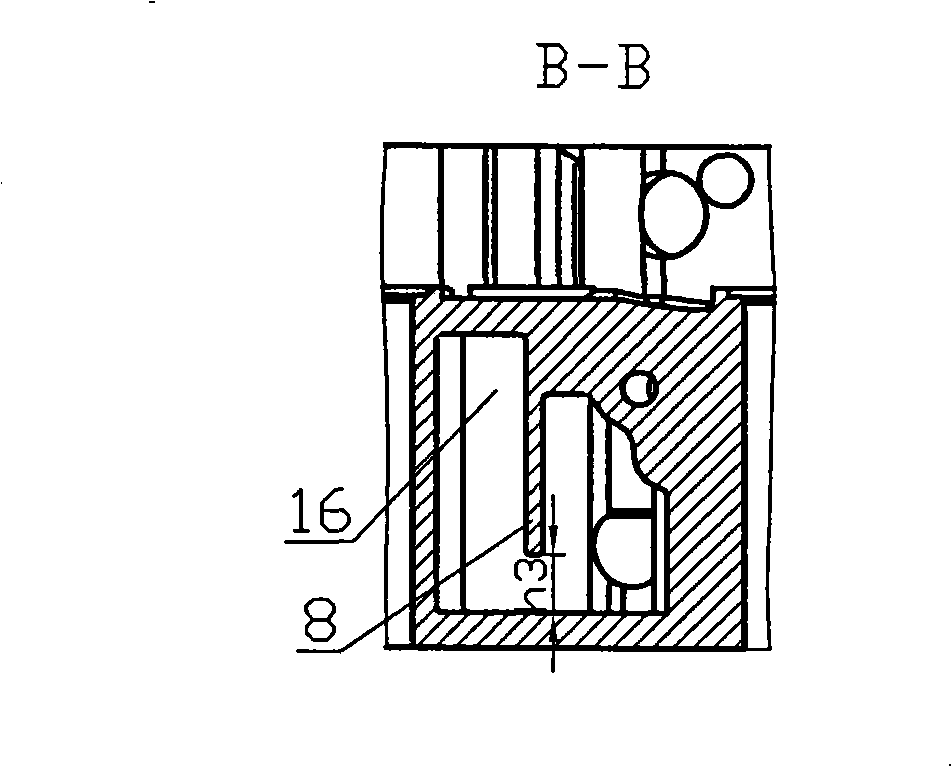

[0024] Figure 1~ Figure 4 As shown, it mainly includes: water outlet 1, first deflector 2, multiple water inlets 3 (including 3a, 3b, 3c, 3d), second deflector 4, third deflector 5, bolt holes Seat 6, fourth deflector 7, fifth deflector 8, water inlet 9, nose bridge area 10, exhaust valve seat 11, exhaust passage 12, intake valve seat 13, intake passage 14, fuel injector Hole 15, cooling water chamber 16 and cylinder head body 17, etc.

[0025] figure 1, figure 2 and image 3 A specific embodiment of the present invention is a cylinder head of a six-cylinder engine. The cylinder head body 17 is respectively provided with a water outlet 1, a plurality of water inlets 3 (including 3a, 3b, 3c, 3d), a plurality of exhaust valve seats 11, a plurality of exhaust passages 12, and a plurality of intake valves. Seat 13, multiple intake channels 14, mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com