On-line dynamic and static mixer

A kind of mixer, dynamic and static technology, applied in the direction of fluid mixer, mixer, chemical instruments and methods, etc., can solve the problems of poor medium rectification effect, poor automatic adjustment performance, poor mixing effect, etc., to achieve easy installation and equipment. Compact structure, continuous effect of mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

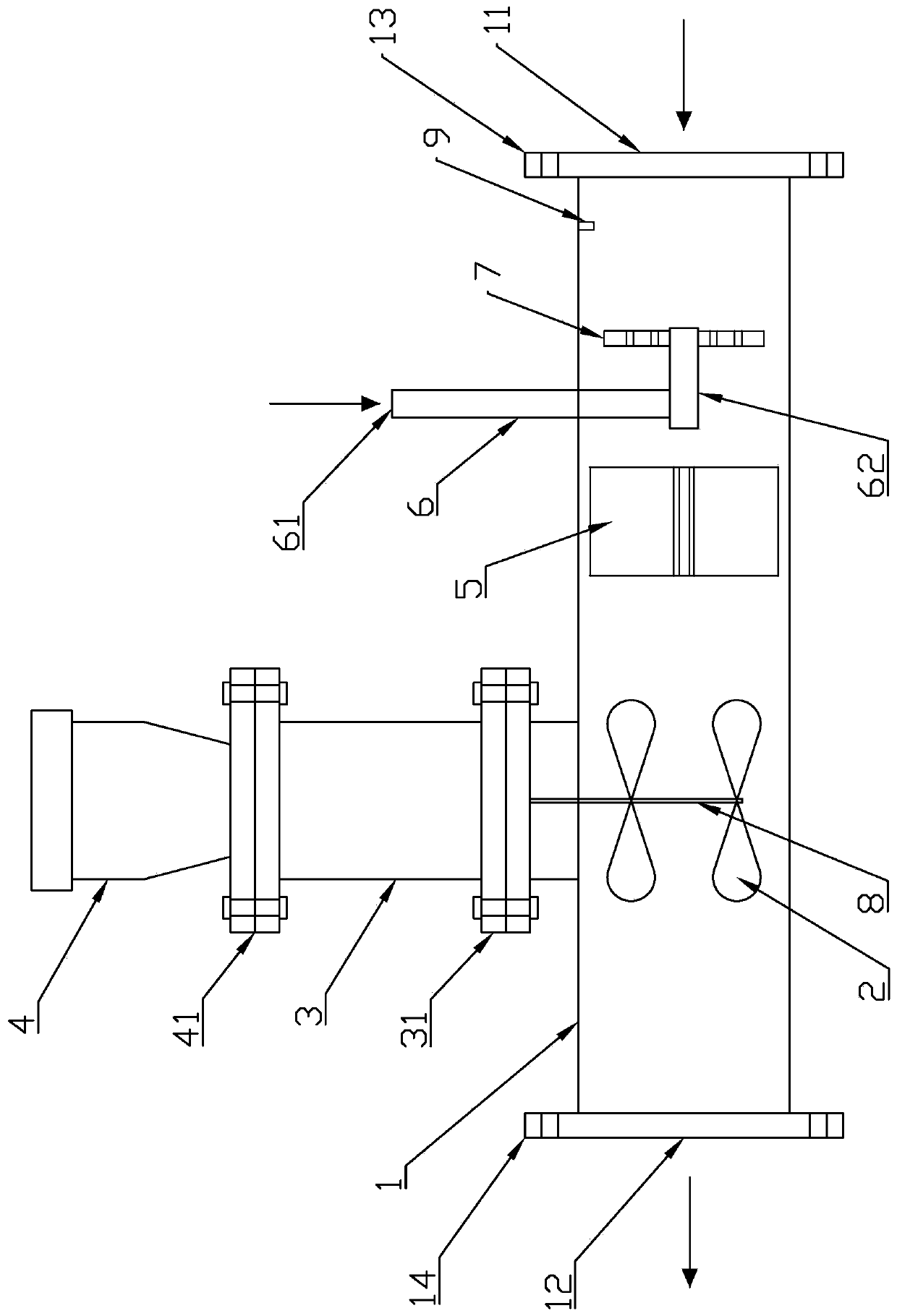

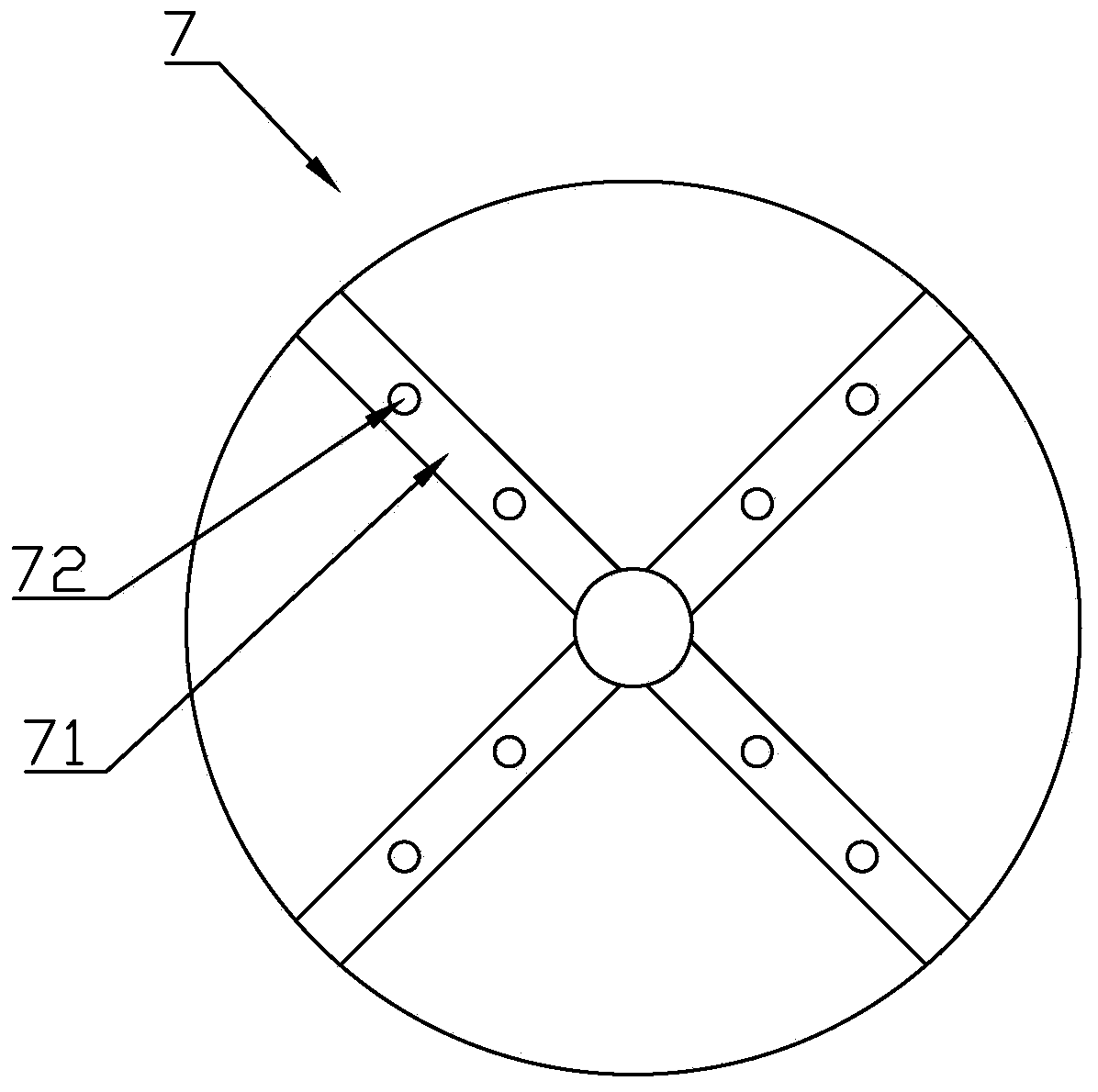

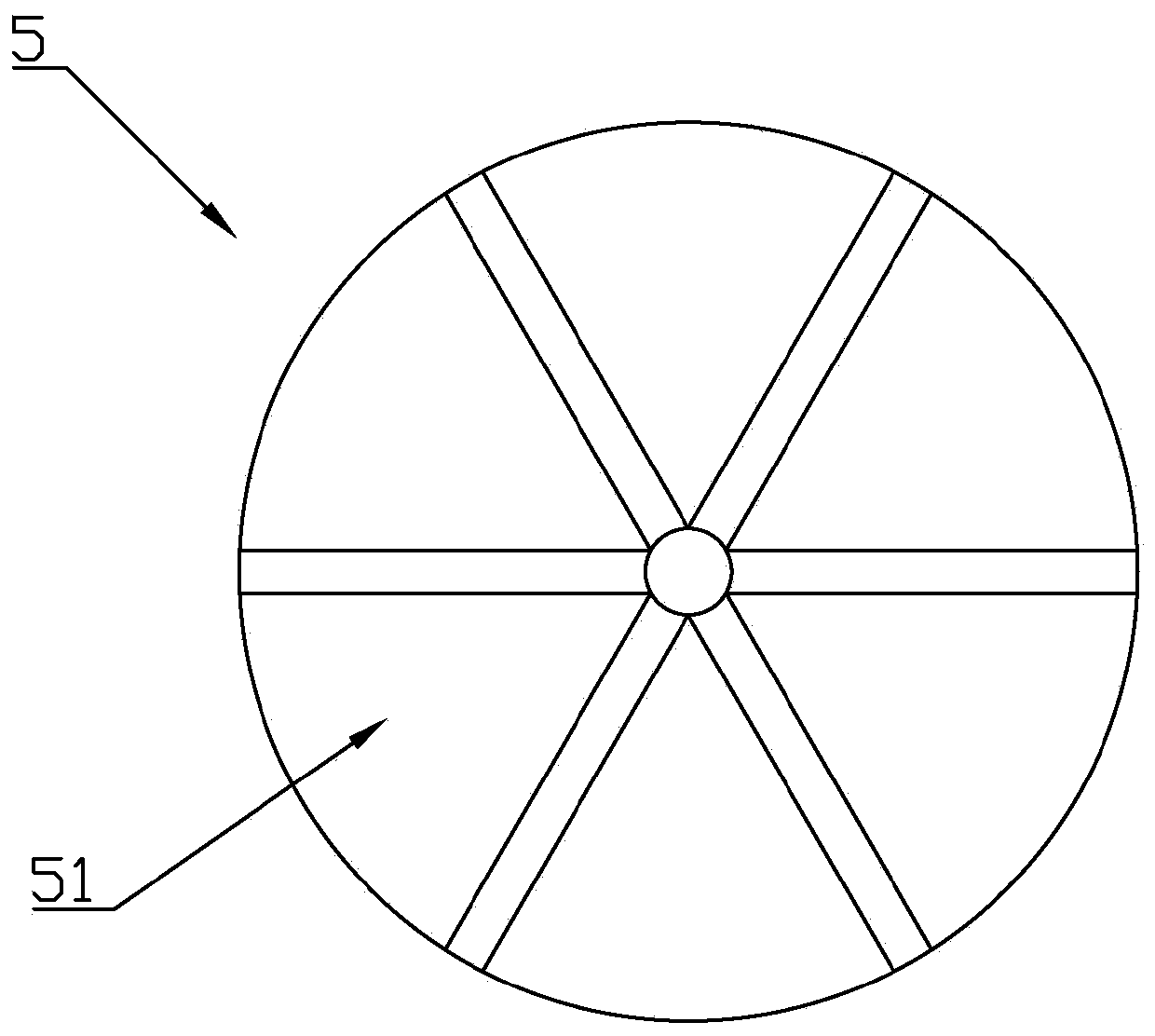

[0032] Such as figure 1 Shown, the present invention provides a kind of online dynamic and static mixer, has:

[0033] The cylinder body 1 has a liquid inlet 11 at the front end and a mixing outlet 12 at the rear end. The liquid inlet 11 and the mixing outlet 12 are respectively provided with flanges 13 and 14 for connecting with the pipes at the front and back of the equipment;

[0034] The injection conduit 6 is used to add medium to the cylinder body 1. It extends into the cylinder body 1 from the radial side of the cylinder body 1 near the front end, and its outer end is a medium inlet 61. Axial tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com