Corrugated expansion joint press-fitting tool

A technology of press-fitting tooling and expansion joints, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity and low assembly efficiency, and achieve the effects of reducing labor intensity, improving efficiency, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

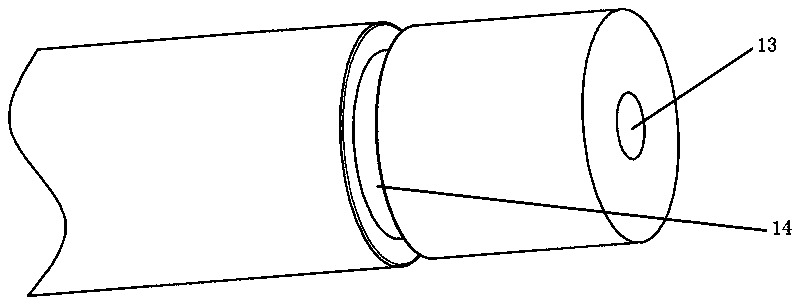

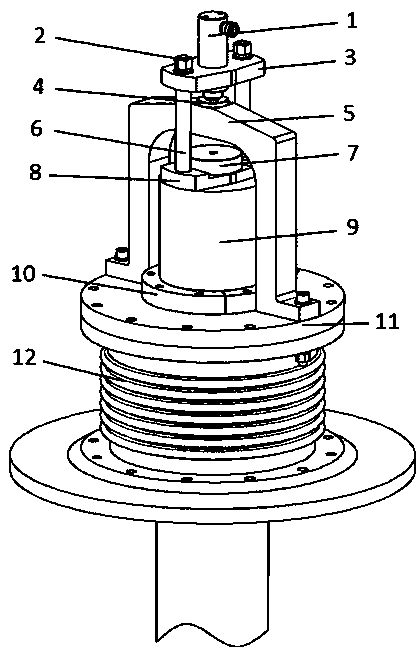

[0033] The structure of the corrugated telescopic joint pressing tooling of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] Such as figure 2 As shown, the bellows expansion joint pressing tooling includes a fixing frame, a pressure applying structure, and a force transmission frame 5 . Wherein, the fixing frame is fixedly connected to the protruding end of the central conductor 9, the pressure applying mechanism is fixed on the fixing frame, and the end of the pressure applying mechanism facing the central conductor 9 is the pressure applying output end. The force transmission frame 5 includes a top pressure end and a force bearing end, the top pressure end presses on the end flange 11 of the corrugated expansion joint 12, the force bearing end is set corresponding to the pressure application output end of the application mechanism, when the pressure application mechanism outputs When in action, the pressure outpu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap