Platform carrier and an assembly for additive manufacturing

A technology of additive manufacturing and platform, applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve problems such as irreplaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

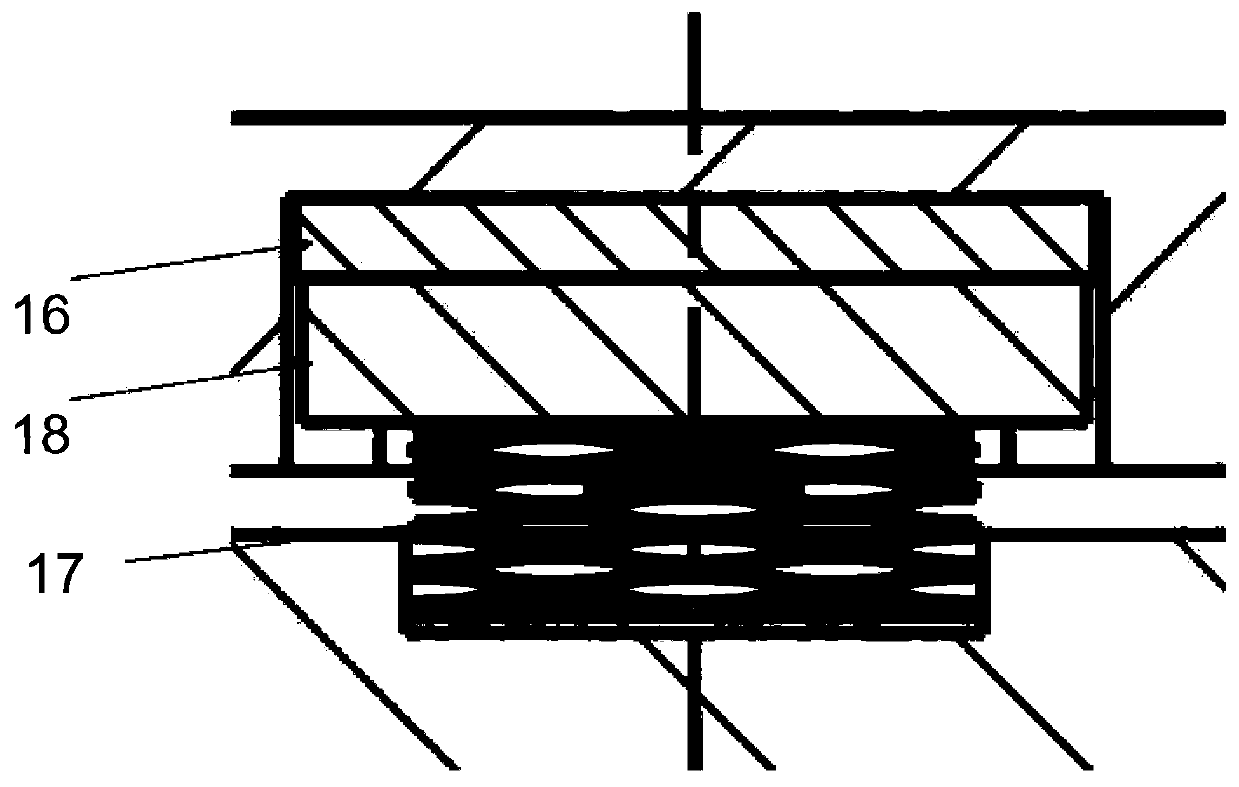

[0034] figure 1 A 3-dimensional view of an embodiment of a platform carrier comprising an upper part 11 and a lower part 12 is shown. At least one heating element is integrated between the upper part and the lower part, and setscrew boxes are embedded in the lower part. The set screw box includes set screws 13 which can be mounted through the platform carrier from its bottom surface and protrude from the top surface of the platform carrier so that additional elements such as building plates can be fixed on the platform carrier. on top.

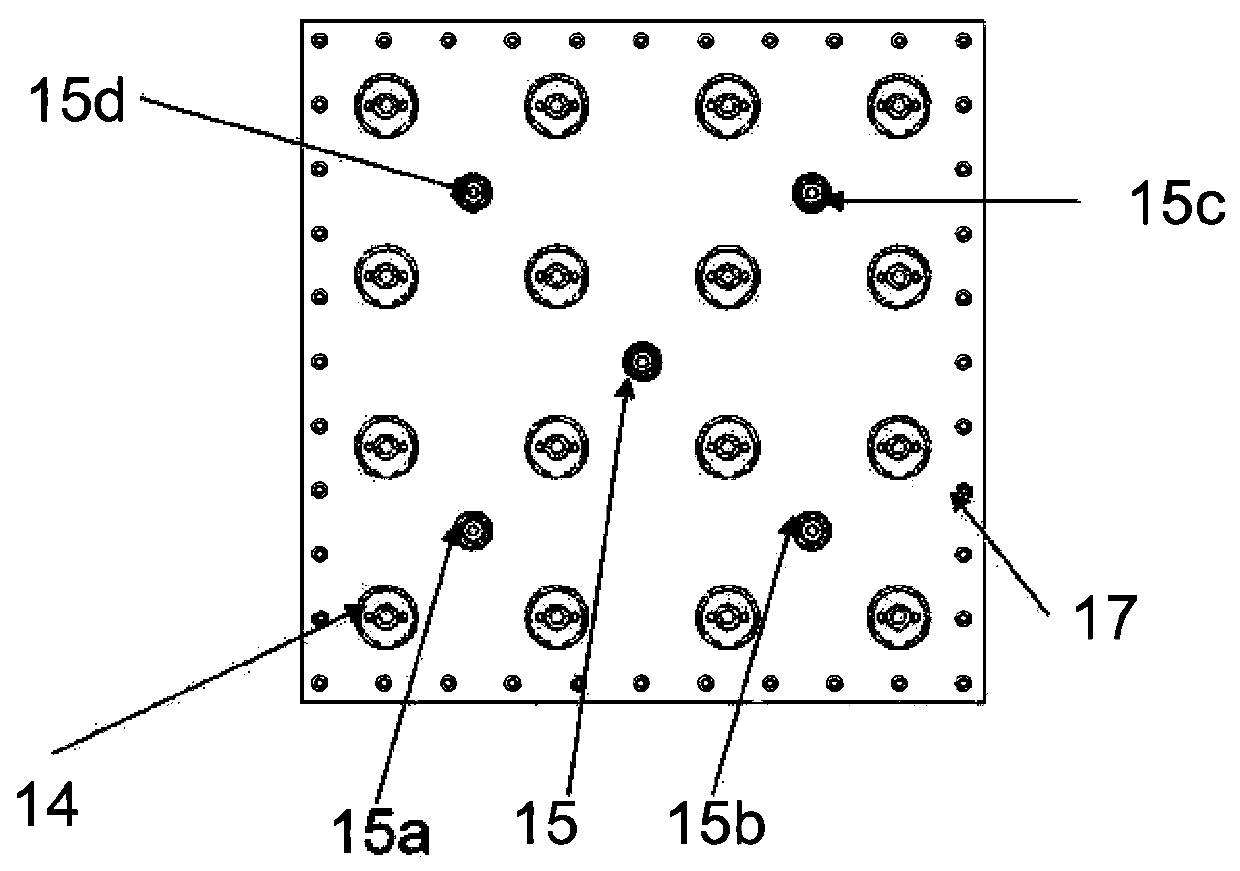

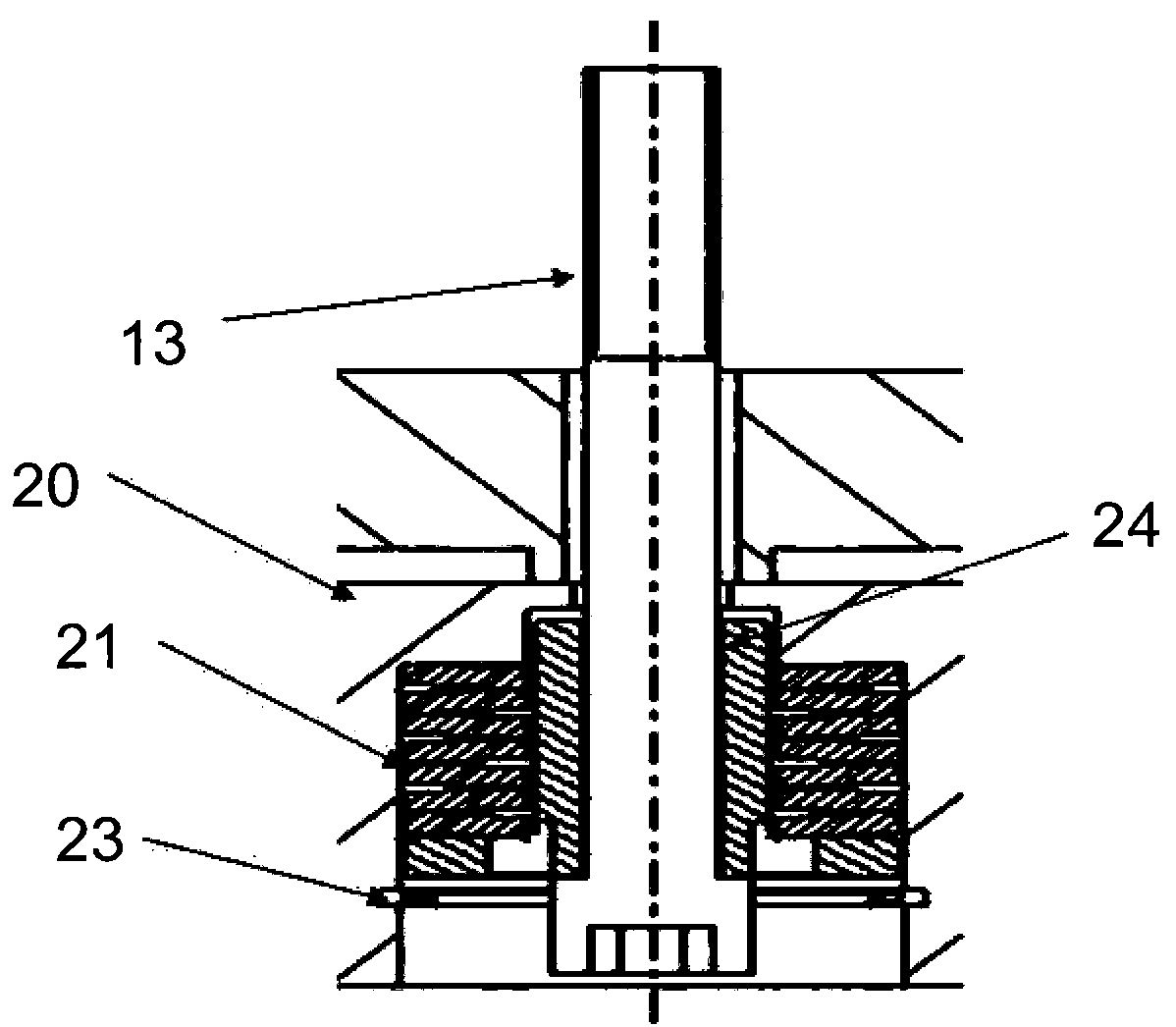

[0035] figure 2 A bottom view of the platform carrier is shown. In this embodiment, sixteen set screw boxes 14 are provided in the platform carrier for receiving sixteen set screws 13, each of which is composed of a disc spring pack 21, The sleeve 24 and the locking element 23 are formed. However, the number of the fixing screw box and the fixing screws is not limited to sixteen. In the middle of the bottom surface, a first drawbar thre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap