Stirring equipment

A technology of mixing equipment and mixing tank, which is applied in the field of concrete mixing, can solve problems such as single mixing direction, uneven mixing, and poor mixing quality, and achieve the effects of high mixing efficiency, diverse mixing directions, and poor mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

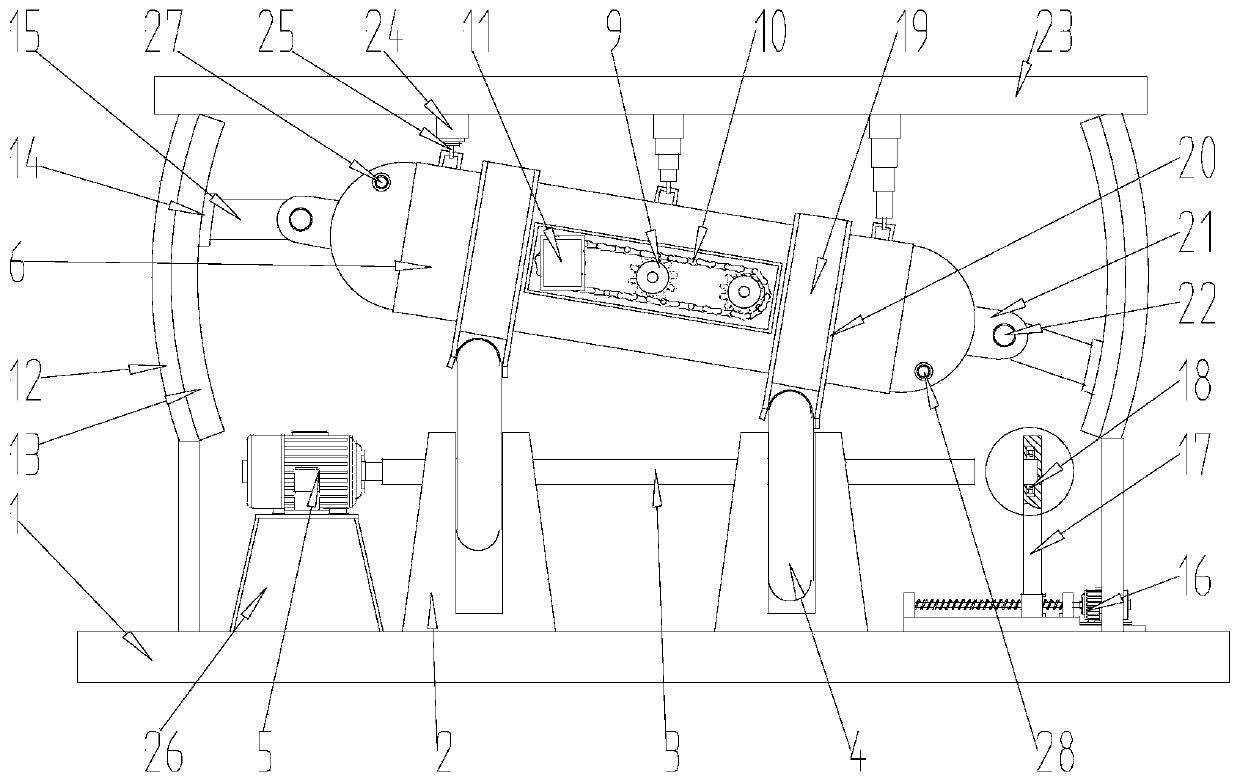

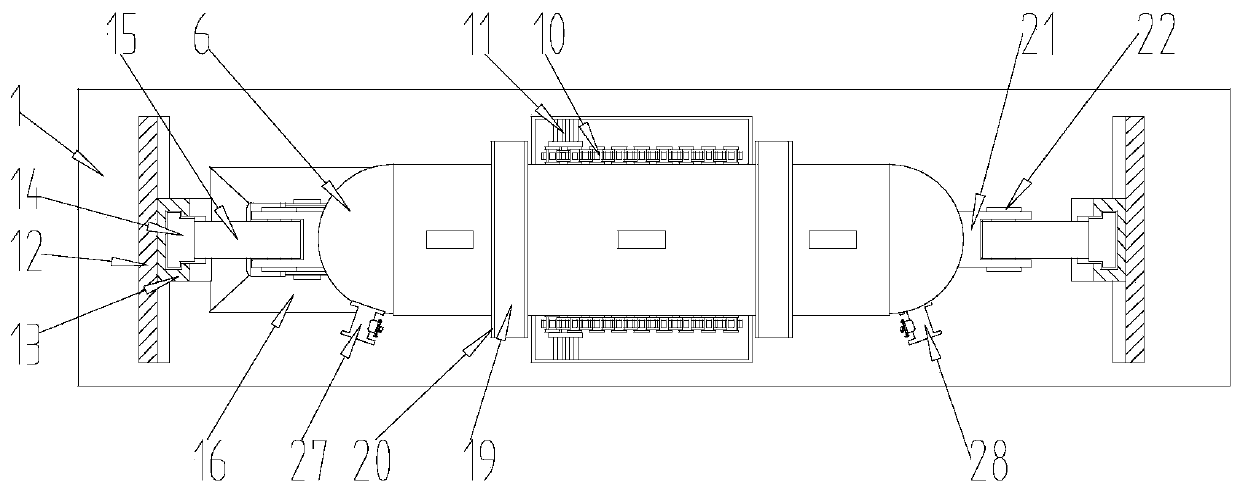

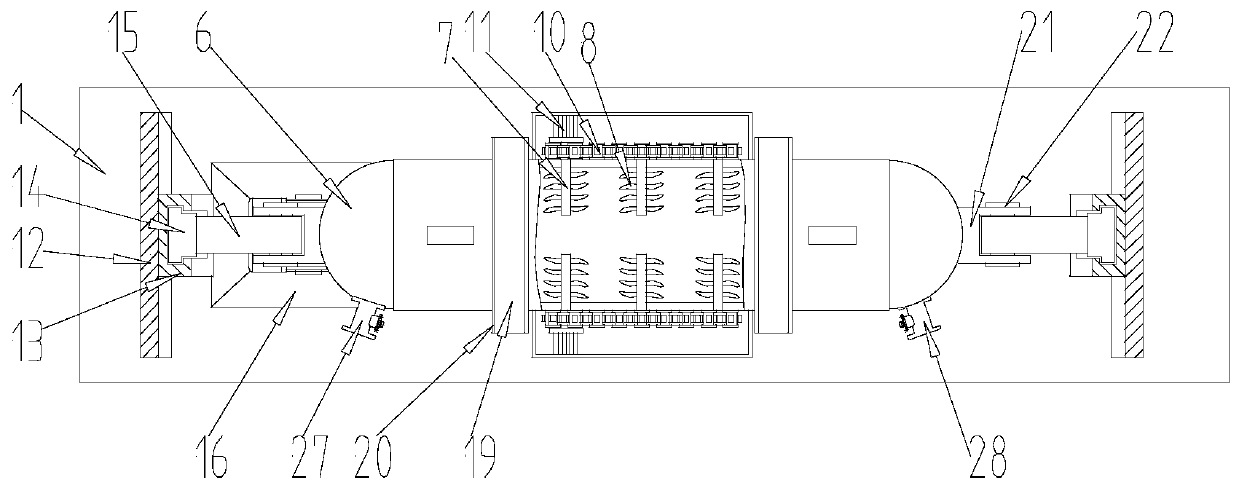

[0032] A stirring device, comprising a base 1, the base 1 is provided with a pair of supports 2 with the same structure, the pair of supports 2 are provided with an external stirring structure, the external stirring structure is provided with an internal stirring structure, the base 1 is provided with a fixed structure, The fixed structure is connected to the external stirring structure, and the base 1 is provided with a locking structure;

[0033] It should be noted that the base 1 is mainly used to install a pair of supports 2, the pair of supports 2 are used to install the external stirring structure, the internal stirring structure is installed on the external stirring structure, and the fixed structure is used to limit the position of the external stirring structure. The locking structure is used to fix the position of the external stirring structure when it is not working.

[0034]The external stirring structure mainly includes: a first rotating shaft 3, a pair of cams 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com