Gantry crane combined beam device and installation method

A gantry crane and combined technology, which is applied in the directions of transportation and packaging, load hanging components, supporting structures, etc., can solve the problems of reduced operating efficiency, increased difficulty of track installation, and inability to continue, so as to reduce construction time and ensure construction efficiency , The effect of streamlining the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

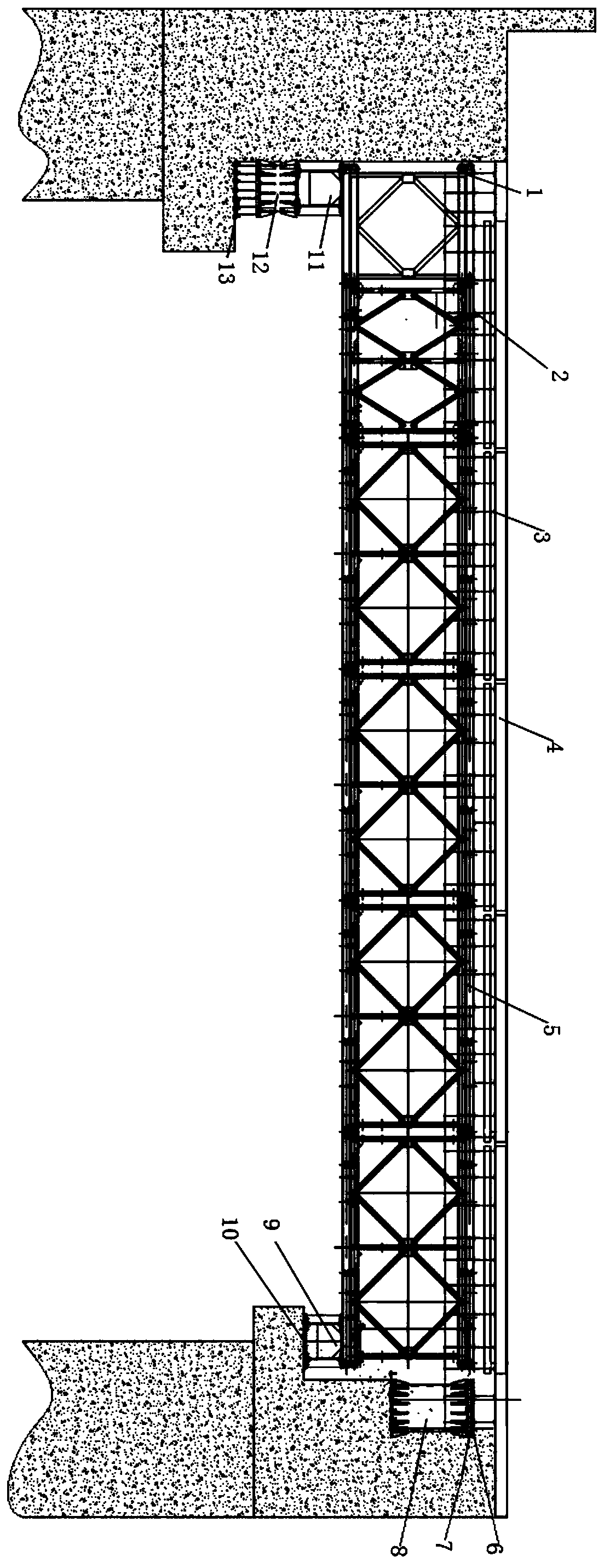

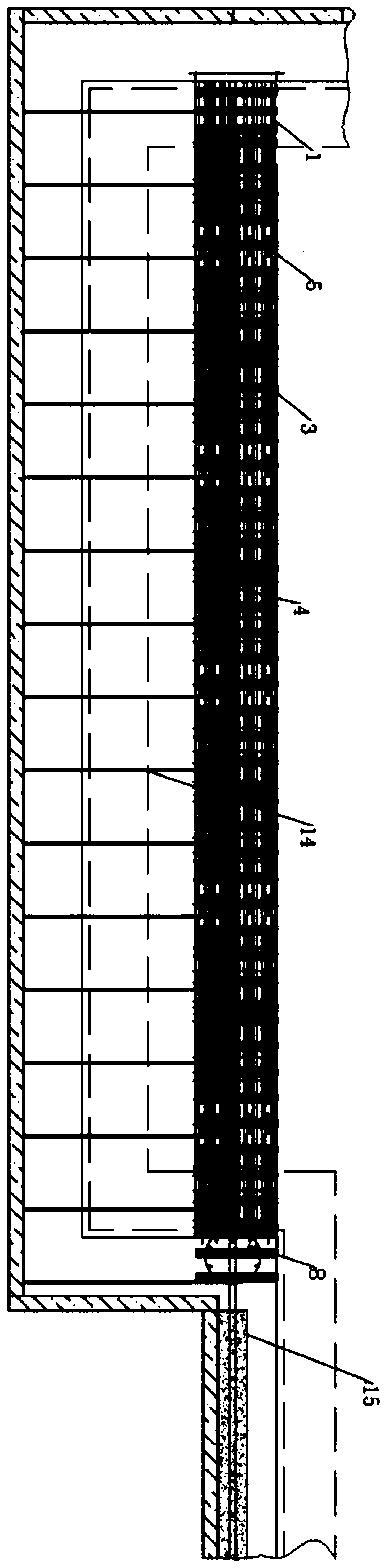

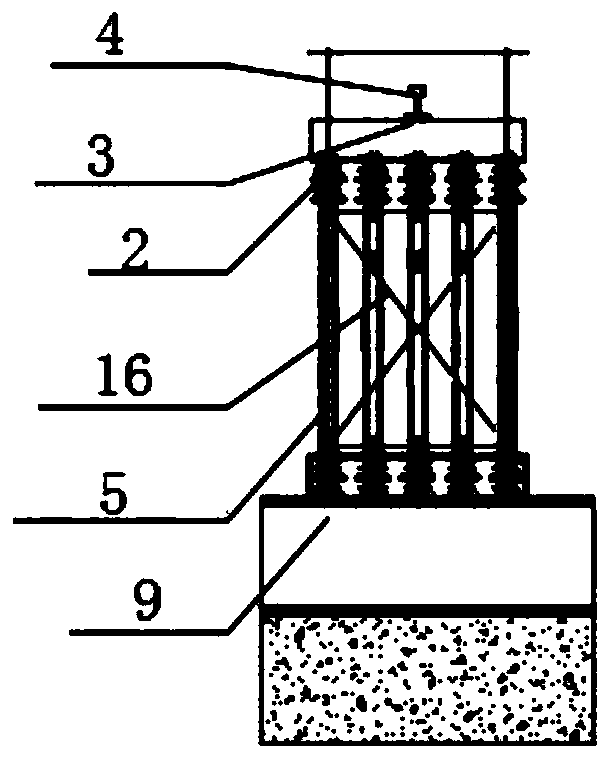

[0024] The main structure of the gantry crane combined beam device involved in this embodiment includes a first Bailey truss 1, a reinforcing chord 2, an I-beam 3, a gantry crane rail 4, a second Bailey truss 5, a steel plate 6, a flange 7, The first steel support 8, the first steel purlin 9, the adjustment steel plate 10, the second steel purlin 11, the second steel support 12, the third steel support 13, the angle steel 14, the concrete beam 15 for the rail, the support frame 16; Both ends of the second Bailey truss 5 of the group are installed with reinforcing chords 2 as the girder body of the gantry crane foundation, and the support frame 16 of X-shaped structure is fixedly installed on the second Bailey truss 5; The "meter" shape is welded and fixed to form a distribution beam. The distance between adjacent I-beams 3 does not exceed 50cm. The bottom of the I-beam 3 is welded and fixed to the reinforcing chord 2, and the top is fixed to the gantry crane rail 4 by welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com