Special vehicle for repairing grabbing arm structure of crane by using wind power

A technology for cranes and special vehicles, which is applied in the directions of cranes, motor vehicles, and vehicles used for freight transportation, can solve the problems that the wheels cannot be rotated, cannot be well shielded from rainwater, and is easy to slide, and achieves the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

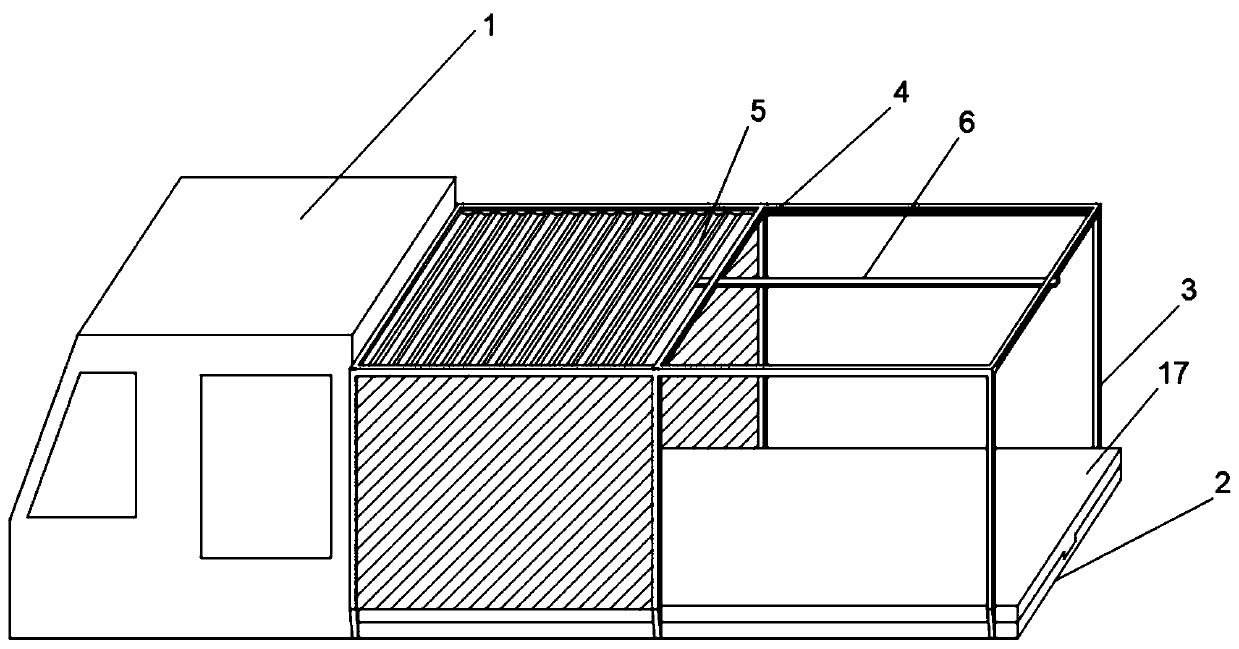

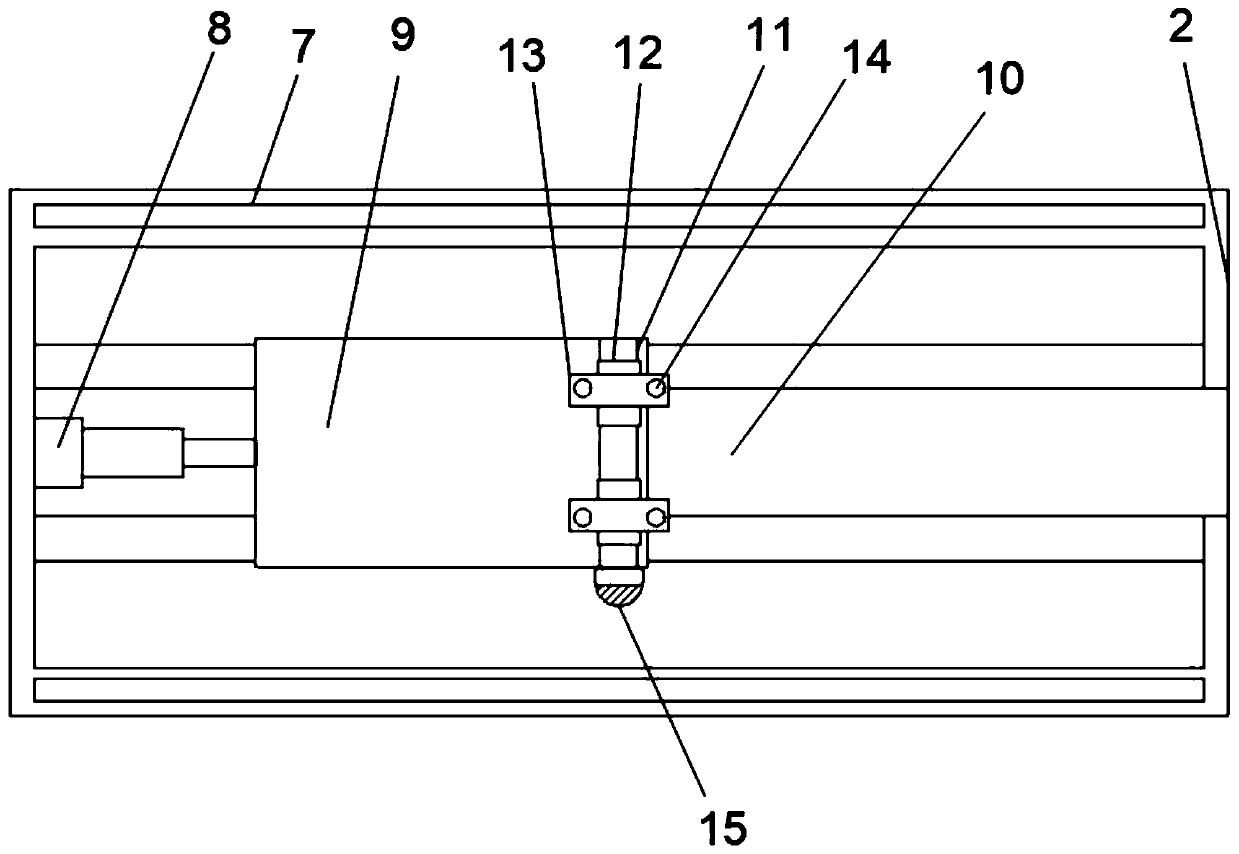

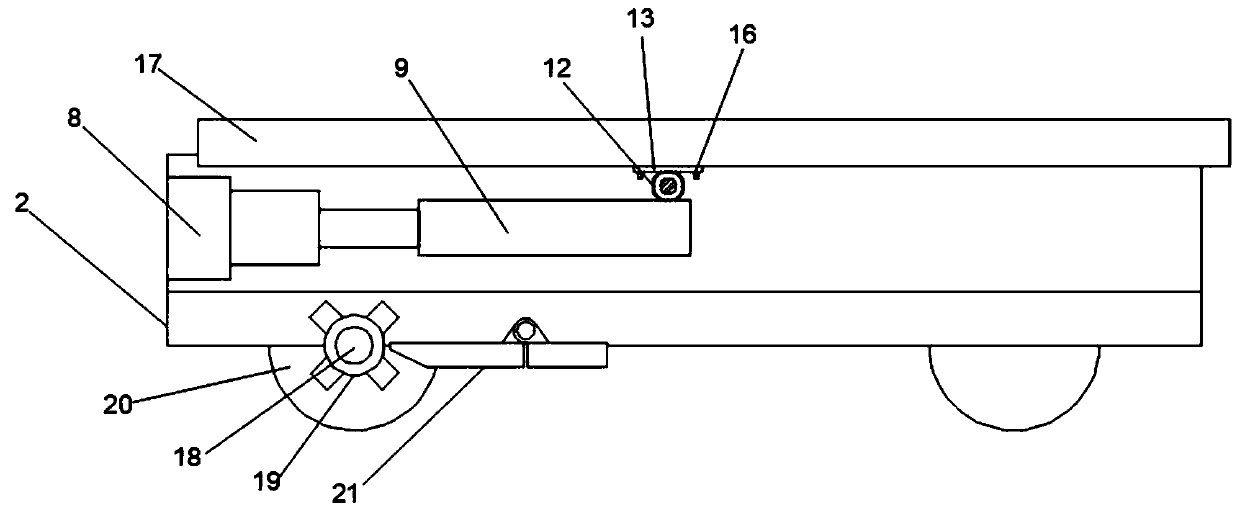

[0025] Such as Figure 1-4 As shown, a special vehicle with a holding arm structure for a wind power maintenance crane includes a main body 1. A bottom plate 2 is provided at the right end of the main body 1 near the lower end. The bottom plate 2 is provided with a bracket 3, and the inner wall of the bracket 3 is provided with The fixed groove 4 is provided with a rain cloth 5, the right end of the rain cloth 5 is provided with a rope 6 near the middle position, and the upper surface of the bottom plate 2 is provided with a chute 7 near the front and rear ends. The inner left side wall of the bottom plate 2 is provided with a hydraulic telescopic rod 8, the right end of the hydraulic telescopic rod 8 is provided with a movable plate 9, and a chute 2 10 is opened between the movable plate 9 and the bottom plate 2. The upper end of the movable plate 9 A rotating shaft 11 is arranged near the right end, a shaft sleeve 12 is arranged on the rotating shaft 11, a mounting plate 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com