17-strand radial tire steel cord

A technology of steel cords and steel wires, applied in the field of 17-strand radial tire steel cords, which can solve the problems of ineffective penetration of rubber, small gaps, and high air content in cords, so as to increase service life, improve corrosion resistance, and avoid failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

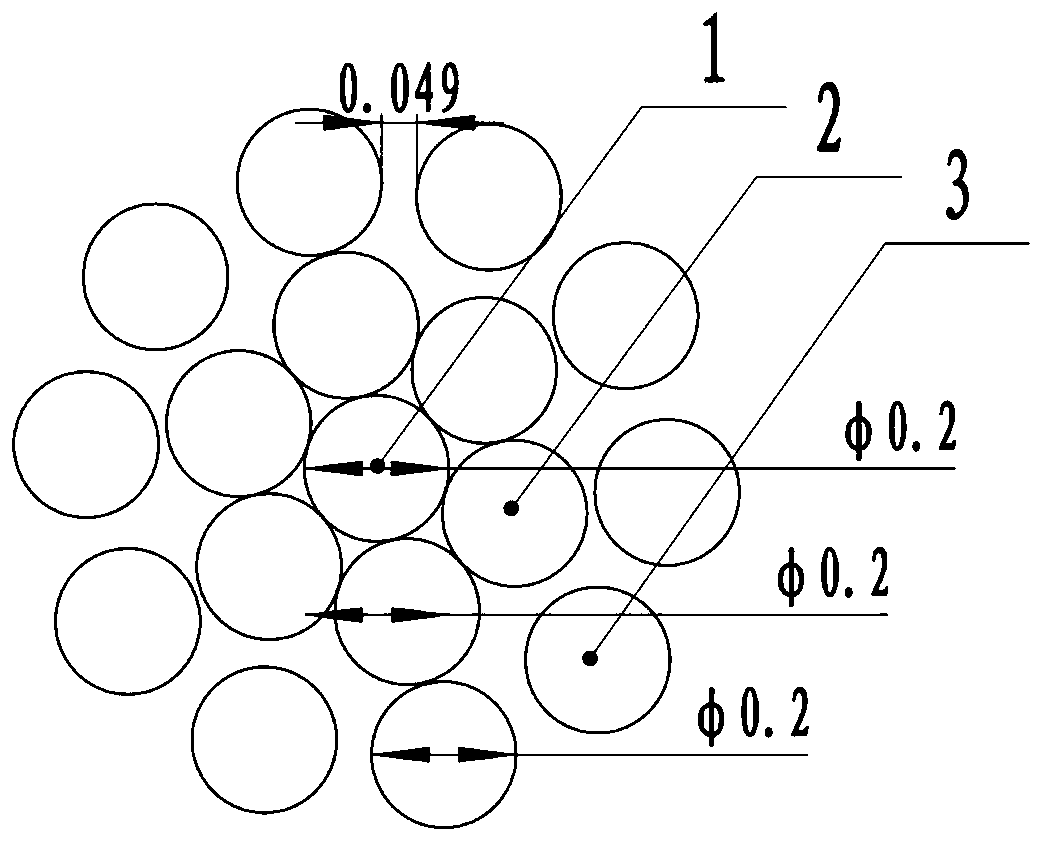

[0027] In this embodiment, the diameters of the core strand 1 steel wire, the middle layer strand 2 steel wire and the outer layer strand 3 steel wire are all 0.20mm, as figure 1 shown. The lay distance of 2 steel wires in the middle layer is 10.0 mm, and the lay length of 3 steel wires in the outer layer is 16.0 mm, that is, the lay length of 2 steel wires in the middle layer is 10.0 mm. 0.625 times. The steel wire of the core strand 1 has no braiding and twisting, and the steel wire of the middle strand 2 and the steel wire of the outer strand 3 adopt the same twist direction, both of which are Z twist. In this embodiment, the steel cord 7+10×0.20ST structure is used for radial tires.

[0028] Table 1 is a comparison table of performance indicators between the 0.22+6+12×0.20HT structural steel cords commonly used in radial tires in the prior art and Example 1 of the present invention:

[0029] Table 1

[0030]

[0031]

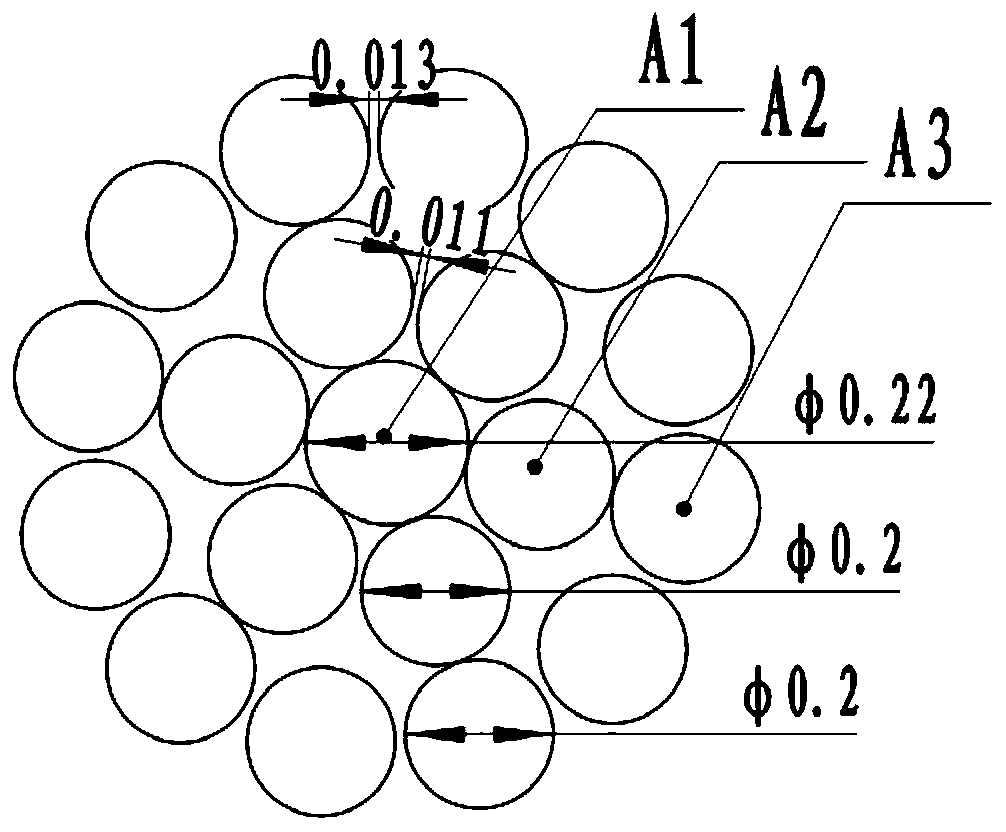

[0032] figure 2 It is a schematic cross-se...

Embodiment 2

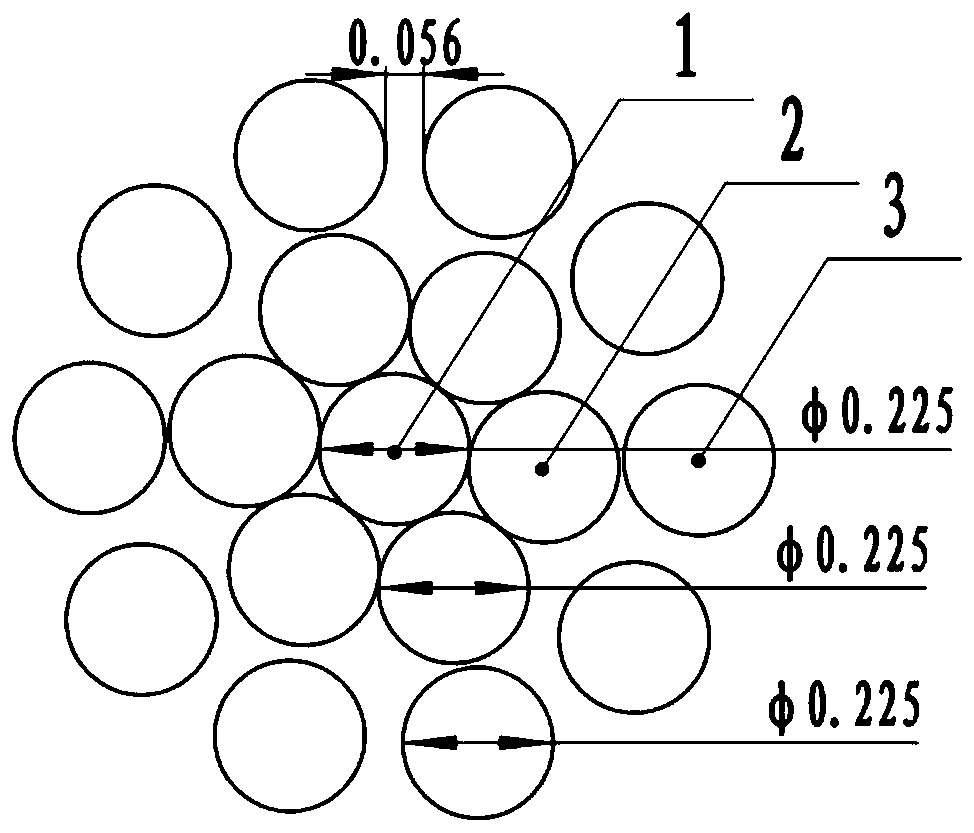

[0034] In the present embodiment, the diameters of the core strand 1 steel wire, the middle layer strand 2 steel wire and the outer layer strand 3 steel wire are all 0.225mm, as image 3 shown. The lay distance of the middle layer strand (2) steel wire twisting is 12.5mm, and the lay length of the outer layer strand 3 steel wire twisting is 18.0mm, that is, the lay length of the middle layer strand 2 steel wire twisting is the same as the outer layer strand 3 steel wire twisting twist 0.695 times the distance. The core strand 1 steel wire has no braiding and twisting, the middle layer strand 2 steel wire and the outer layer strand 3 steel wire adopt the same twist direction, both of which are Z twist. In this embodiment, the steel cord 7+10×0.225ST structure is used for radial tires.

[0035] Table 2 is a comparison table of performance indicators between the 3+9+15×0.225HT structural steel cords commonly used in radial tires in the prior art and the second embodiment of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com