Continuous temperature measuring device for molten steel in steel ladle

A technology of temperature measuring device and ladle, which is applied in the field of infrared temperature measurement, can solve the problems of increasing user maintenance costs, thick transmission cables, inconvenient maintenance, etc., and achieve the effect of reducing the amount of after-sales service, changing the concept of maintenance, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

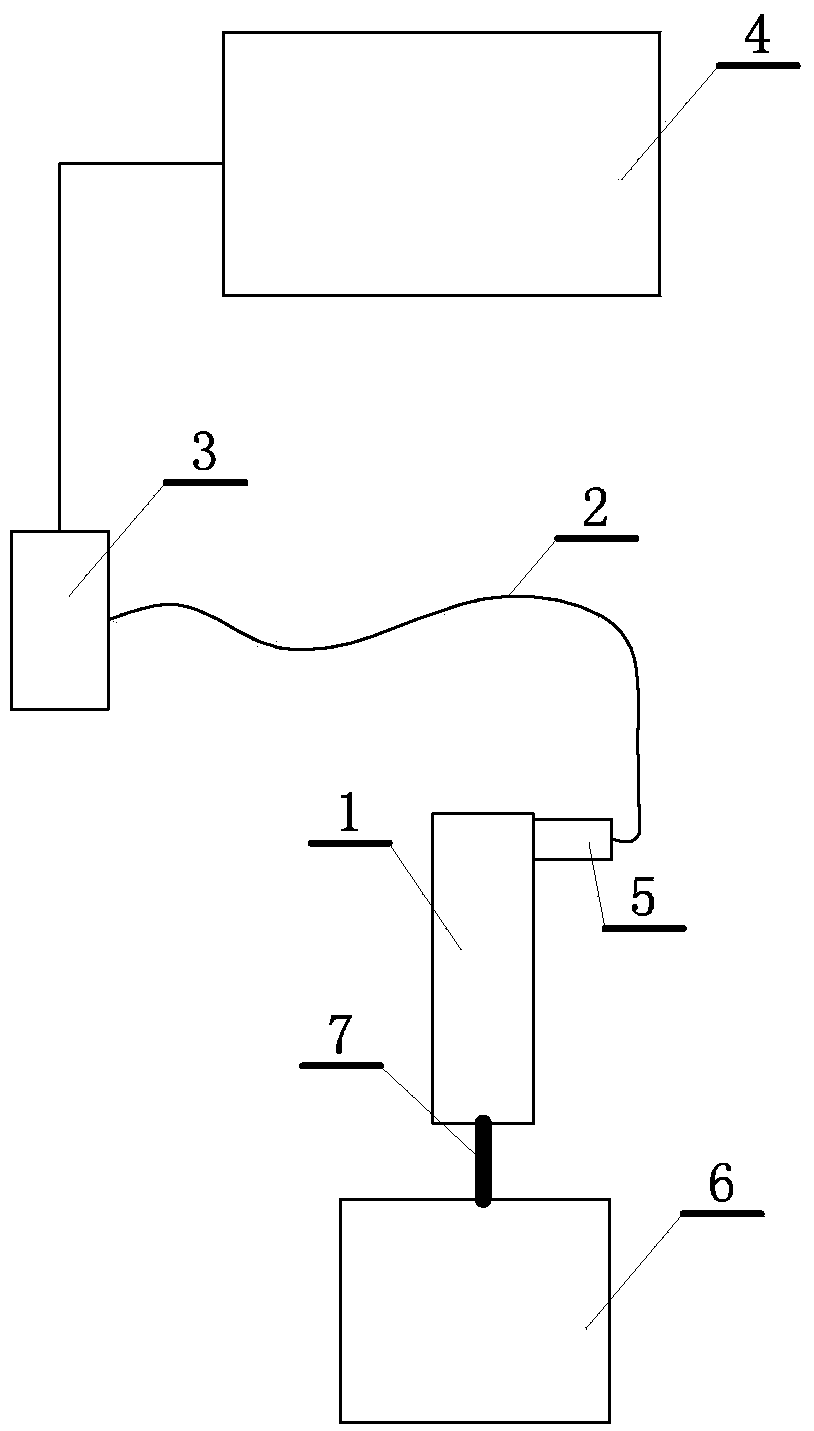

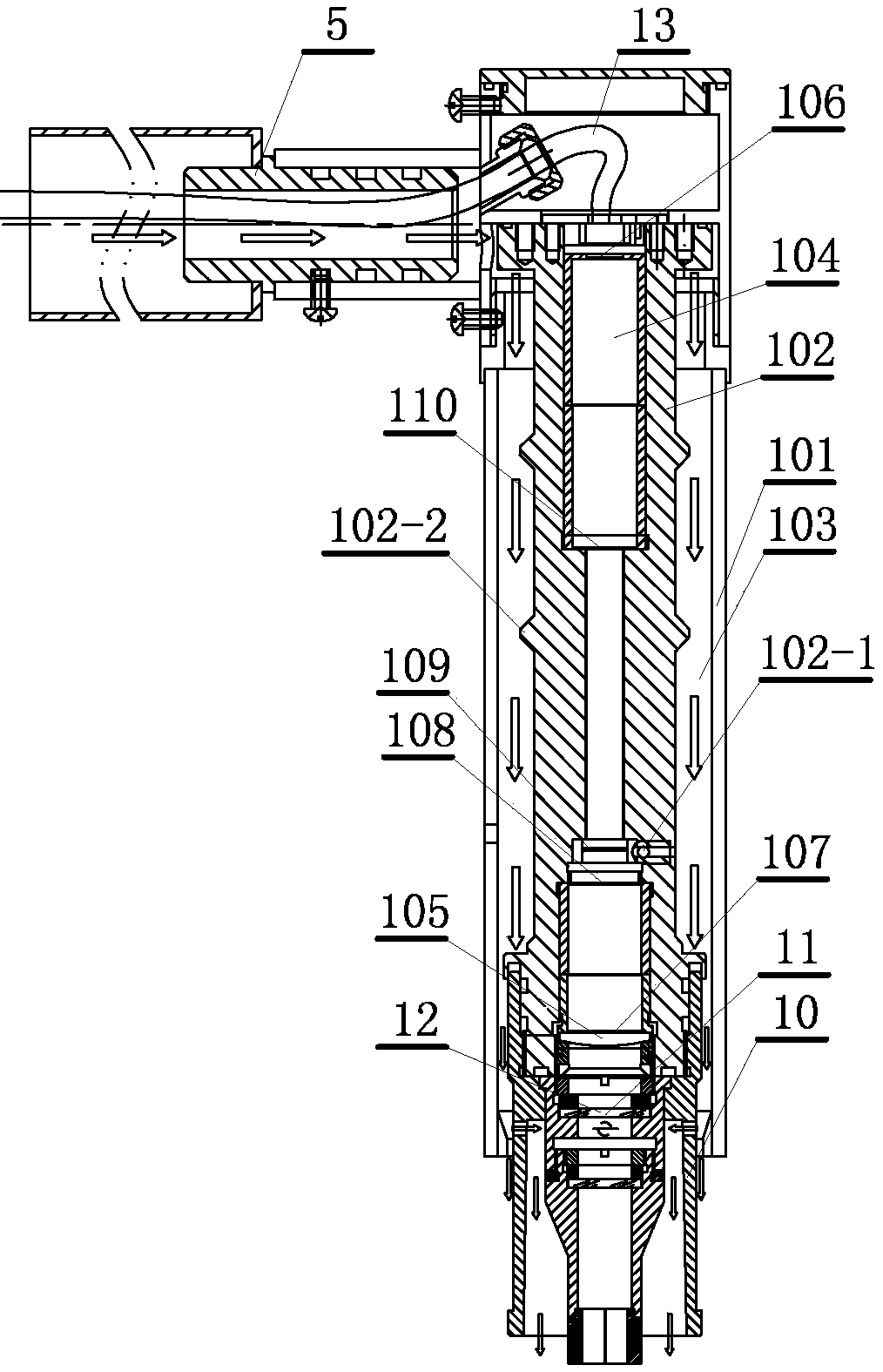

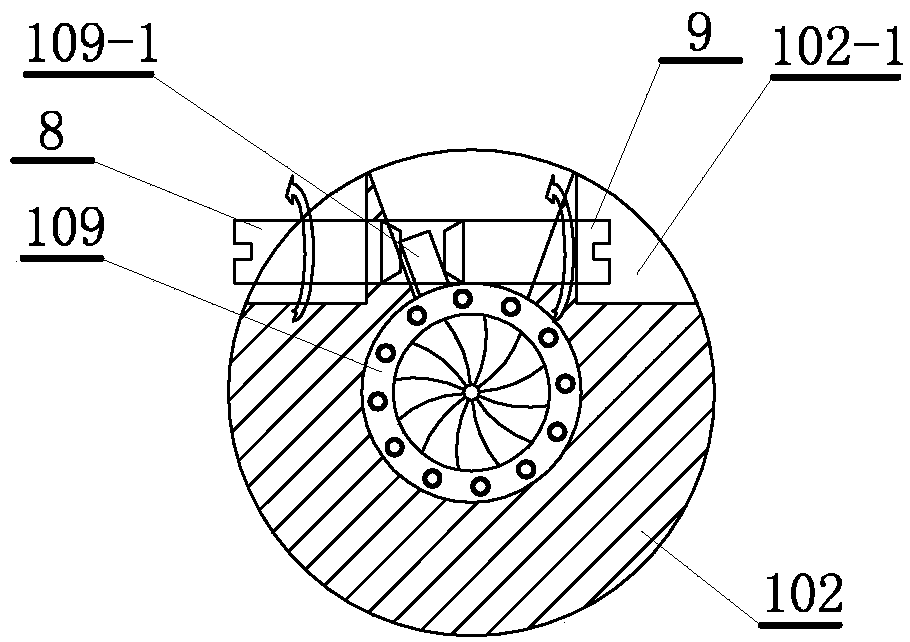

[0019] A ladle molten steel continuous temperature measuring device is used for real-time and continuous temperature measurement of the intermediate ladle of continuous casting. Such as figure 1 and figure 2 As shown, the molten steel continuous temperature measurement device includes an infrared temperature measurement probe 1, a transmission cable 2, a signal processing unit 3 and a display 4. The infrared temperature measurement probe is connected to one end of the transmission cable through a cable interface 5, and the signal processing unit is connected to the cable. At the other end, the signal processing unit is set in a housing and connected to the other end of the cable through a connector. The signal processing unit processes the received infrared temperature measurement signal and sends it to the display for display. The display can be packaged together with the processing unit In one housing, the display in this embodiment is a large-screen display and the signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com