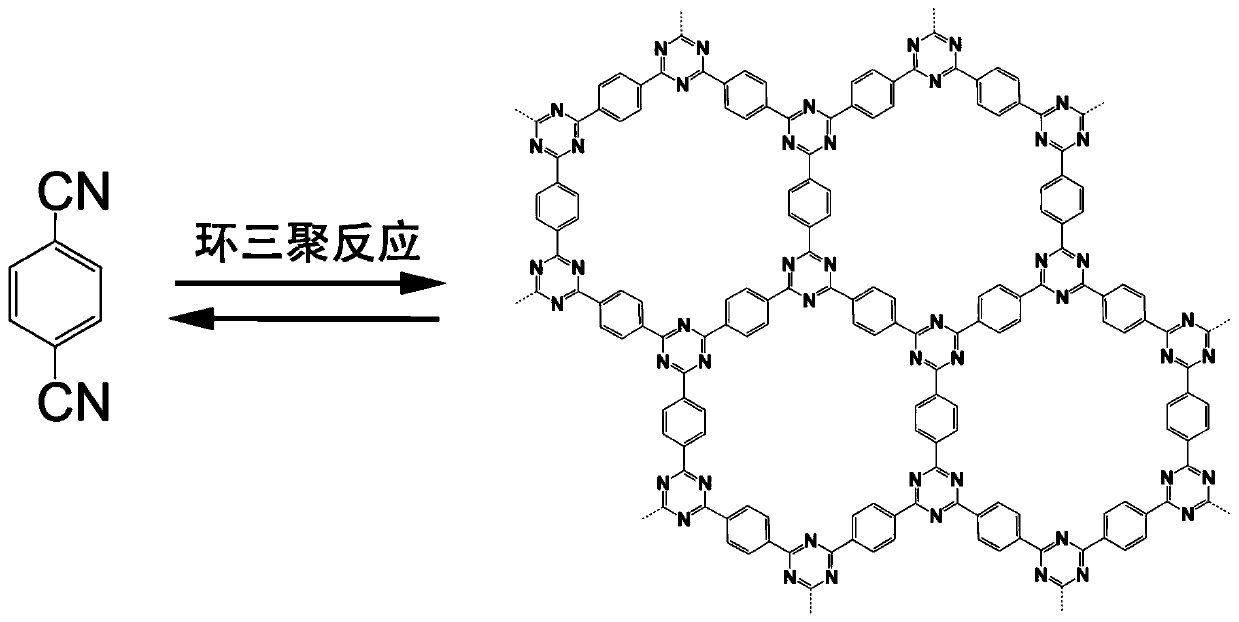

NO2 gas sensor based on covalent triazinyl two-dimensional polymer as well as preparation method and application of NO2 gas sensor

A triazine-based two-dimensional gas sensor technology, applied in the field of nanomaterials, can solve the problems of high working temperature, high detection limit, and poor reproducibility, and achieve low cost, simple preparation process, good reproducibility and reversibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of layered covalent triazine skeleton crystals: 2 mg of terephthalonitrile was dissolved in 10 mL of CH 2 Cl 2middle. Then 10000r min -1 Centrifuge for 5 minutes to remove undissolved terephthalonitrile monomer to obtain a transparent monomer solution. Transfer it to the dropping funnel, then add 1mL of trifluoromethanesulfonic acid into a 250ml round bottom flask, and add the transparent terephthalonitrile monomer solution dropwise into the round bottom flask within 2h , the entire reaction system was stirred at 100° C., condensed and refluxed, and reacted overnight to convert terephthalonitrile monomers as much as possible to form covalent triazine skeleton crystals. After reacting for 4 hours, it can be found that yellow crystals are gradually attached to the round bottom flask. After the reaction is complete (12 hours), the reaction is quenched with 20 mL of ethanol. The filter cake was collected by filtration to obtain a reaction product, and th...

Embodiment 2

[0042] (1) Preparation of layered covalent triazine skeleton crystals: 40 mg of terephthalonitrile was dissolved in 20 mL of CH 2 Cl 2 middle. Then 10000r min -1 Centrifuge for 5 minutes to remove undissolved terephthalonitrile monomer to obtain a transparent monomer solution. Transfer it to the dropping funnel, then add 1mL of trifluoromethanesulfonic acid into a 250mL round bottom flask, and add the transparent terephthalonitrile monomer solution dropwise into the round bottom flask within 2h , the entire reaction system was stirred at 100° C., condensed and refluxed, and reacted overnight to convert terephthalonitrile monomers as much as possible to form covalent triazine skeleton crystals. After reacting for 4 hours, it can be found that yellow crystals are gradually attached to the round bottom flask. After the reaction is complete (12 hours), the reaction is quenched with 40 mL of ethanol. The filter cake is collected by filtration to obtain a reaction product, and t...

Embodiment 3

[0046] (1) Preparation of layered covalent triazine skeleton crystals: 200 mg of terephthalonitrile was dissolved in 20 mL of CH 2 Cl 2 middle. Then 10000r min -1 Centrifuge for 5 minutes to remove undissolved terephthalonitrile monomer to obtain a transparent monomer solution. Transfer it to the dropping funnel, then add 1ml of trifluoromethanesulfonic acid into a 250mL round bottom flask, and add the transparent terephthalonitrile monomer solution dropwise into the round bottom flask within 2h , the entire reaction system was stirred at 100° C., condensed and refluxed, and reacted overnight to convert terephthalonitrile monomers as much as possible to form covalent triazine skeleton crystals. After reacting for 4 hours, it can be found that yellow crystals are gradually attached to the round bottom flask. After the reaction is complete (12 hours), the reaction is quenched with 60 mL of ethanol. The filter cake was collected by filtration to obtain a reaction product, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com