Speed-reduction wire winder and dust collector thereof

A cord reel and speed reduction technology, applied in vacuum cleaners, electrical components, cleaning equipment, etc., can solve the problems of easy disconnection of power plug wires, limited power cord speed, easy to throw and hurt users, etc., and achieves low structural strength, Small size and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

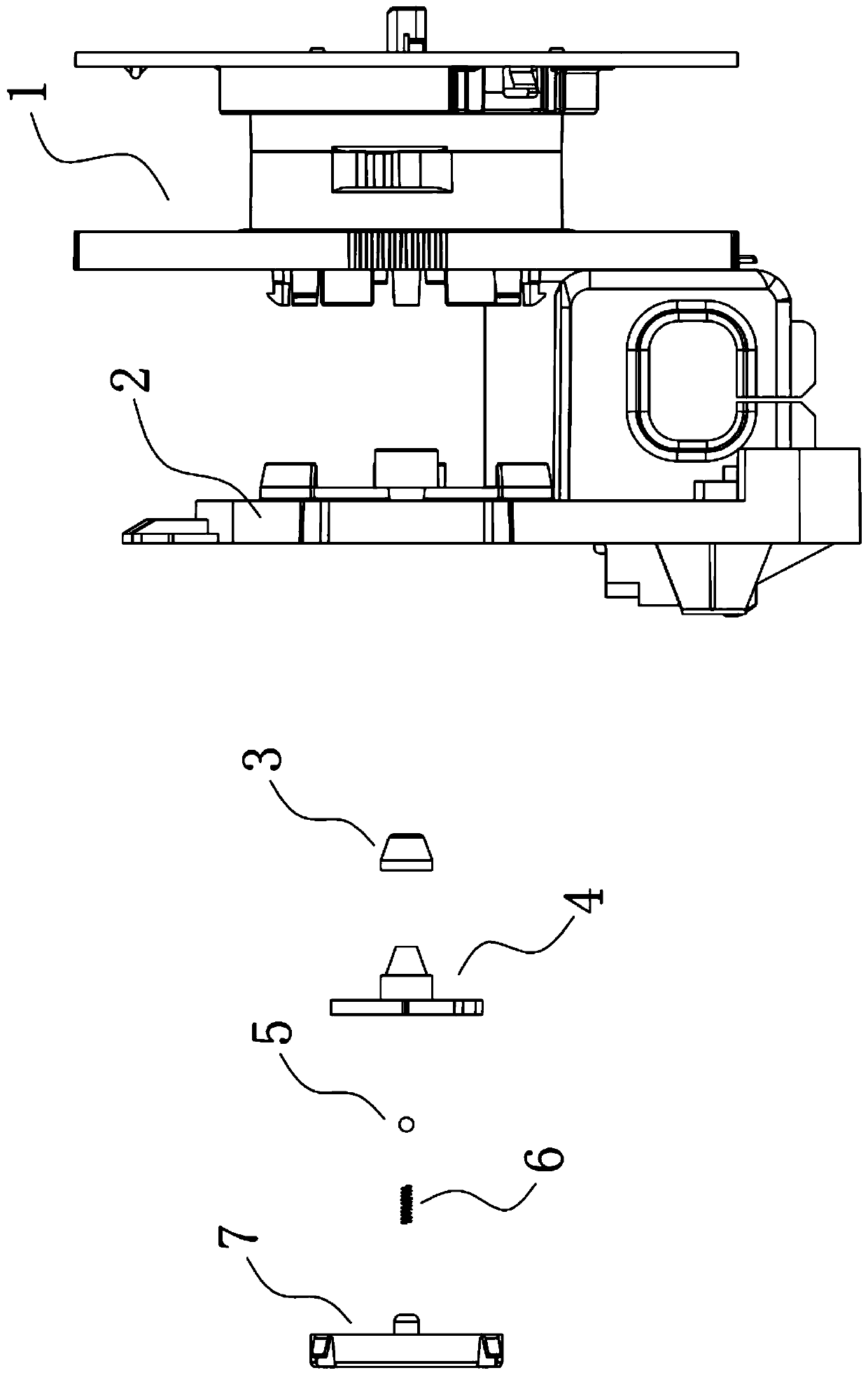

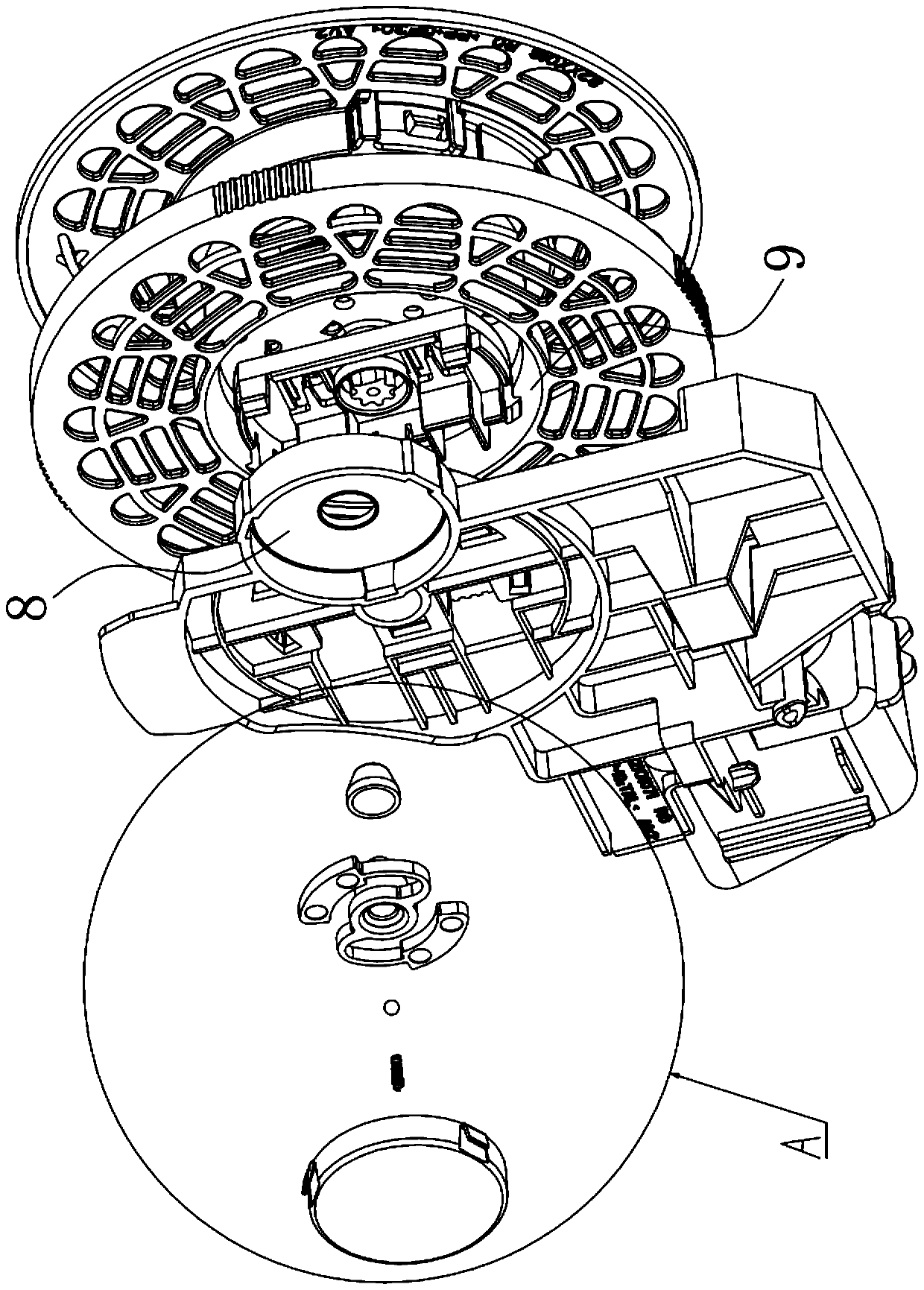

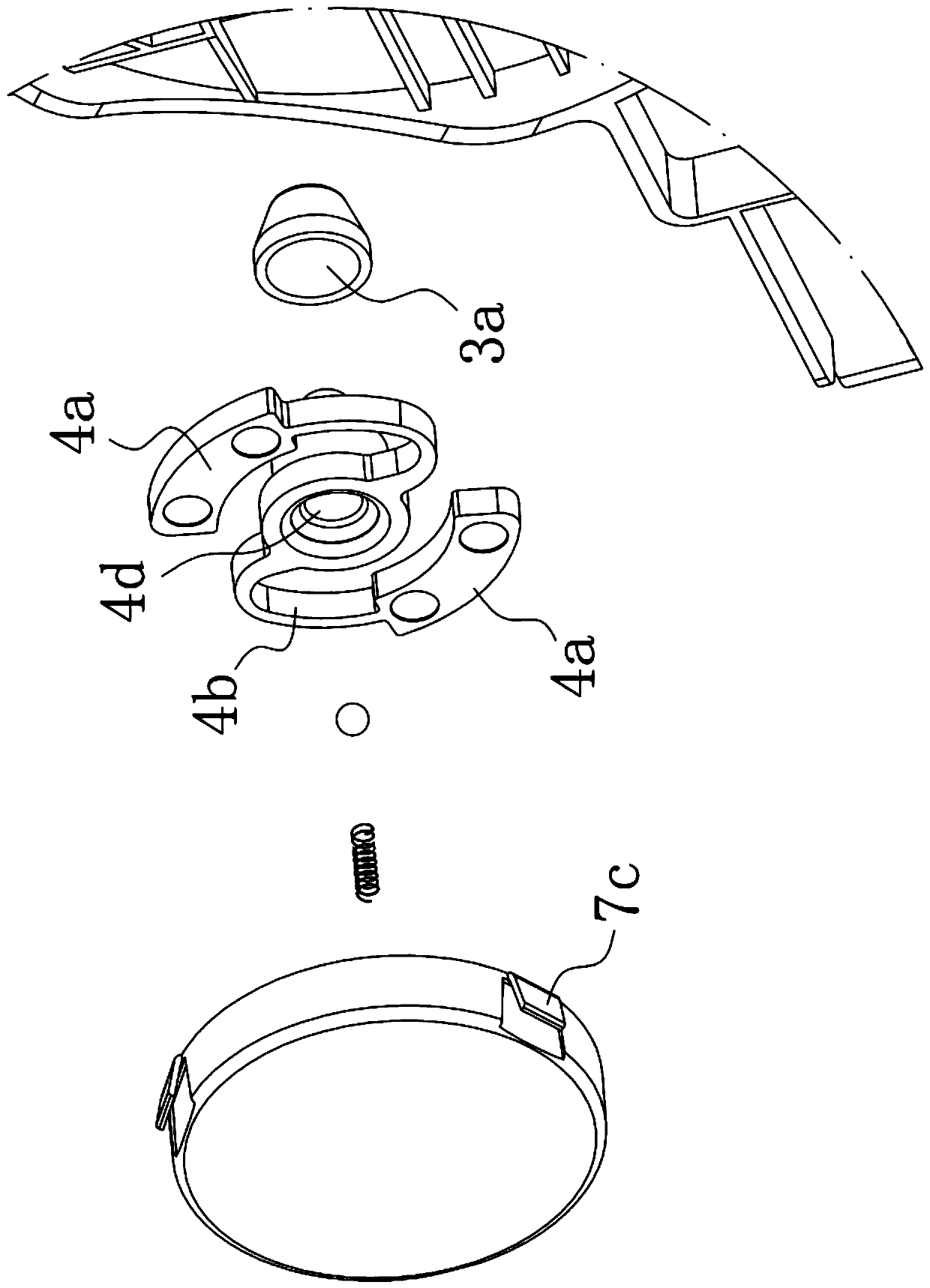

[0037] In order to achieve the purpose of the present invention, a speed-reducing wire reel includes: a winding mechanism, including a winding roller 1 for winding electric wires, and the winding roller 1 is movably connected with a bracket 2 through a rotating shaft 1a; The brake disc 4 connected to the wire roller 1 by transmission, the brake disc 4 rotates synchronously with the winding roller 1, the bracket 2 is provided with a concave circular pit 8, the brake disc 4 is located in the circular pit 8, and the mouth of the circular pit 8 is covered There is a brake disc cover 7; the brake disc 4 is elastically connected with a brake pad 4a, and the radial outward movement distance of the brake pad 4a is positively correlated with the rotational speed of the brake disc 4 until the brake pad 4a contacts the circular pit 8 or the brake disc cover 7 friction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com