Feed screening and stirring device using differential centrifugation

A technology of feed mixing and differential speed centrifugation, which is applied to mixers with rotating agitation devices, feed, mixer accessories, etc., can solve the problems of large labor, waste, time-consuming and labor-intensive feed, etc., to achieve improved mixing efficiency, simple mechanism, Easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

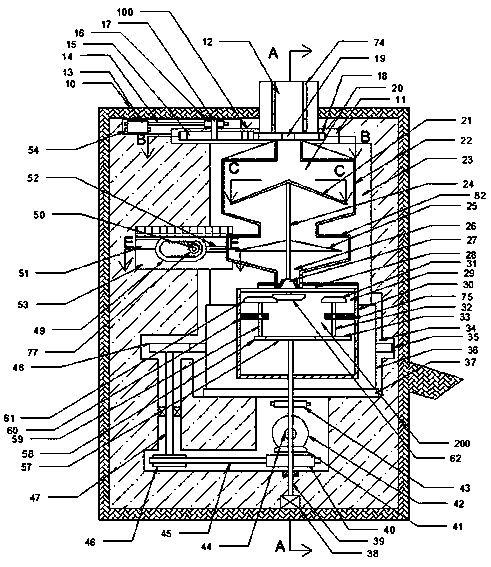

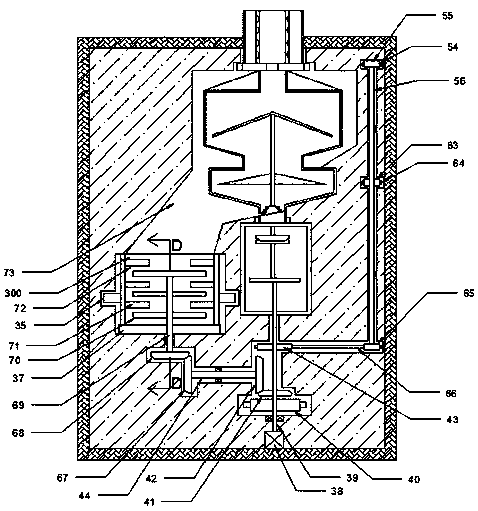

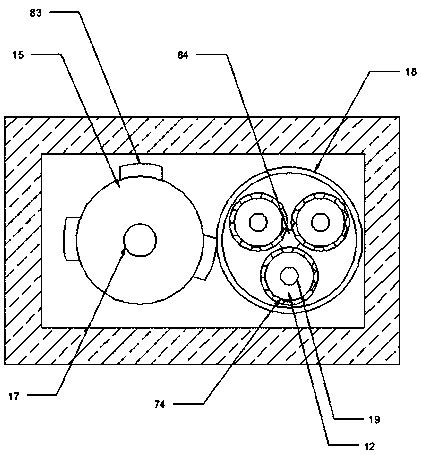

[0023] like Figure 1-6 As shown, a differential speed centrifugal screening feed stirring device includes a housing 10, the housing 10 is provided with a discharge chamber 11, and the discharge chamber 11 is provided with a discharge mechanism 100, and the feed that is dropped in Stored under the action of the discharge mechanism 100, the housing 10 is provided with a screening chamber 20 located at the lower end of the storage chamber 12, and the screening chamber 20 is provided with a rotatable second shaft 24, the The upper end of the second rotating shaft 24 is fixed with a screening turntable 21, the outer end of the screening turntable 21 is fixed with a filter screen 22, the lower end of the screening turntable 21 is fixed with a buffer turntable 25, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com