A method for preparing ultra-fine high-white micropowder by removing impurities from granite fine-grained stone powder at full-grain level

A granite and full-grain grading technology, applied in chemical instruments and methods, solid separation, grain processing, etc., can solve the problems of high equipment power and high energy consumption, and achieve the effects of increased yield, large sedimentation area, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

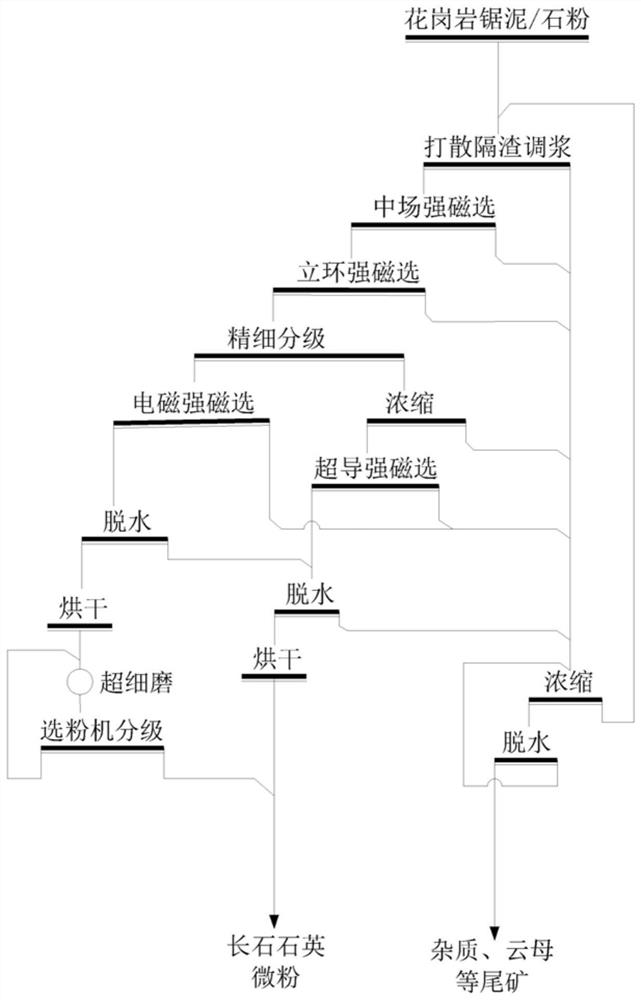

[0038] Taking the solid waste sawing sludge from a granite stone mine in a certain place in Henan Province as the test object, the test product was tested by Foshan Ceramic Research Institute Testing Co., Ltd. 2 0: 3.18-4.06%, Na 2 0: 5.26-6.06%, Fe 2 0 3 : 2.15-2.83%, Al 2 o 3 : 16.26-18.38%, SiO 2 : 65.77-72.60%, TiO 2 : 0.12-0.44%, CaO: 2.07-2.77%, MgO: 0.09-0.65%, product particle size, D50=24.86μm, raw ore whiteness 6.5-8.6%, process flow chart of beneficiation is as follows figure 1 shown.

[0039] Slag separation classification: After the sample is classified to +40 mesh, the product is large particle impurities and coarse sand, and the concentration of the overflow pulp of the spiral classifier is adjusted to 25-30%;

[0040] Two-stage magnetic separation for impurity removal: the first-stage magnetic separation adopts a semi-countercurrent drum permanent magnet magnetic separator with a field strength of 0.6T, and the second-stage magnetic separation adopts a h...

Embodiment 2

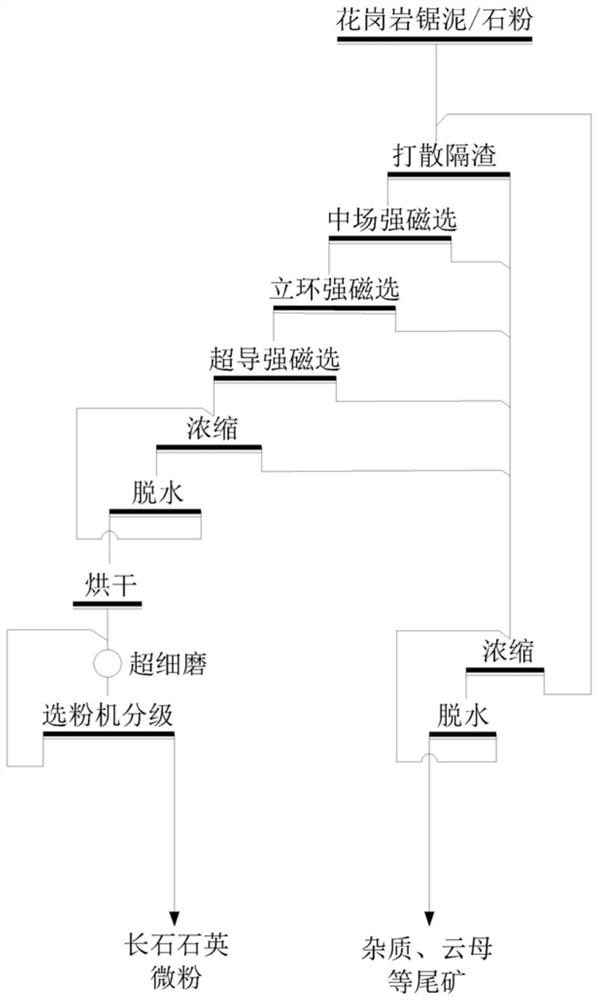

[0048] Taking sesame white granite stone powder in a stone industrial park in Henan Province as the test object, the test product was tested by Foshan Ceramic Research Institute Testing Co., Ltd. The analysis of the sawn mud raw ore samples was calculated by mass percentage, and the K in the samples was 2 0: 3.36%, Na 2 0: 5.56%, Fe 2 0 3 : 2.17%, Al 2 o 3 : 17.16%, SiO 2 : 67.10%, TiO 2 : 0.37%, CaO: 2.77%, MgO: 0.58%, product particle size D50 = 12.34μm, raw ore whiteness 10.7, process flow chart as figure 2 shown.

[0049] Classification of slag separation: the sample is screened and graded + 40 mesh products are large particles of impurities and coarse sand, and the concentration of the selected ore pulp is adjusted to 25-30%; because the raw ore particle size is relatively fine, the content of the coarse particle is low, and the coarse particle is no longer classified. The first-stage magnetic separation adopts a semi-countercurrent magnetic separator with a field...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com