Cylinder sleeve centrifugal casting machine

A centrifugal casting machine and cylinder liner technology, which is applied in the field of casting and processing of auto parts, can solve the problems of prolonging the molding cycle, internal stress of the cylinder liner, affecting the molding quality of the cylinder liner, etc., and achieves the effect of improving the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

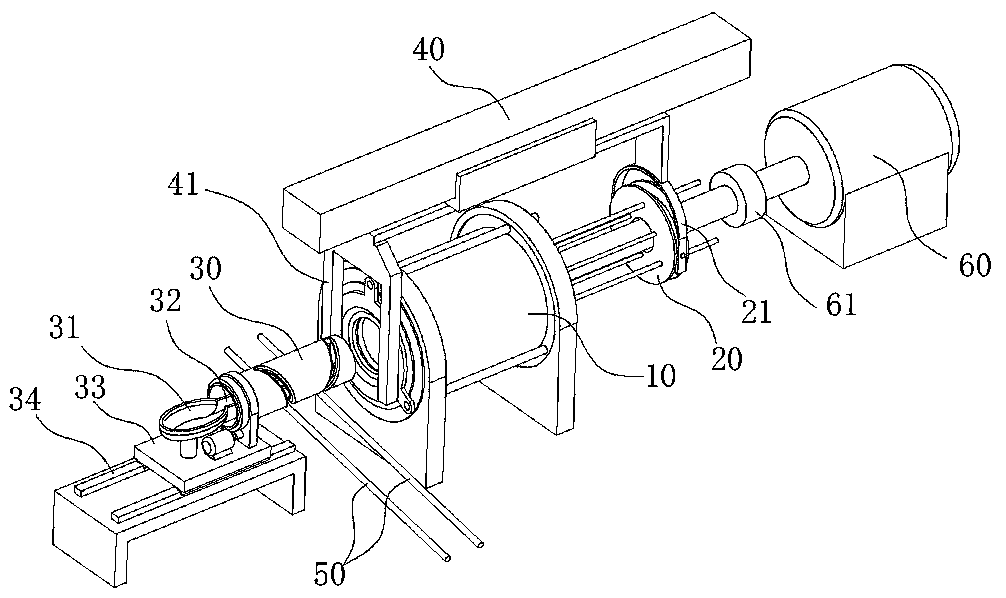

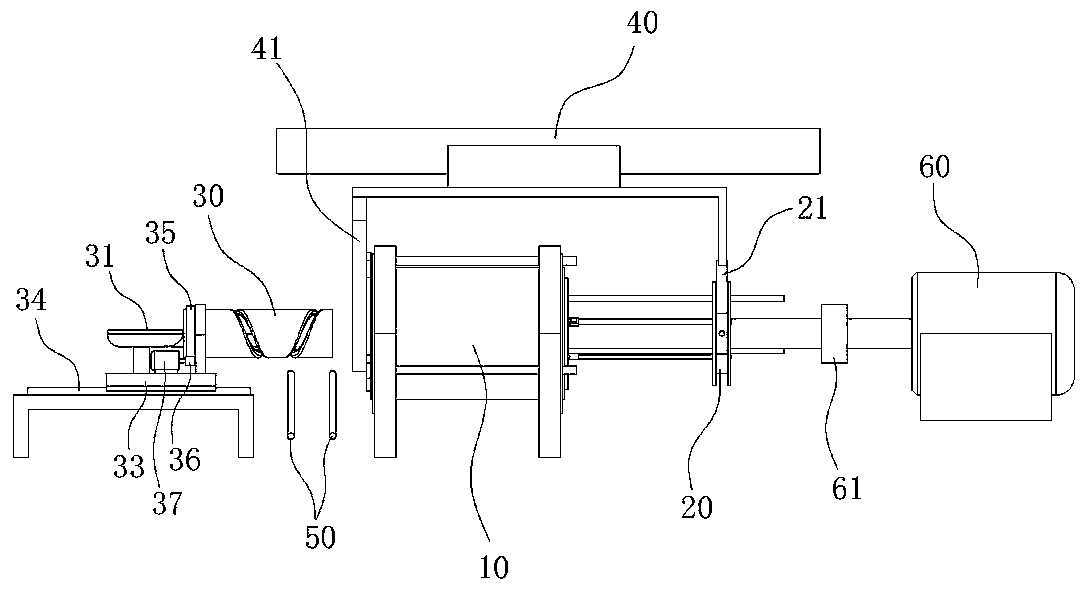

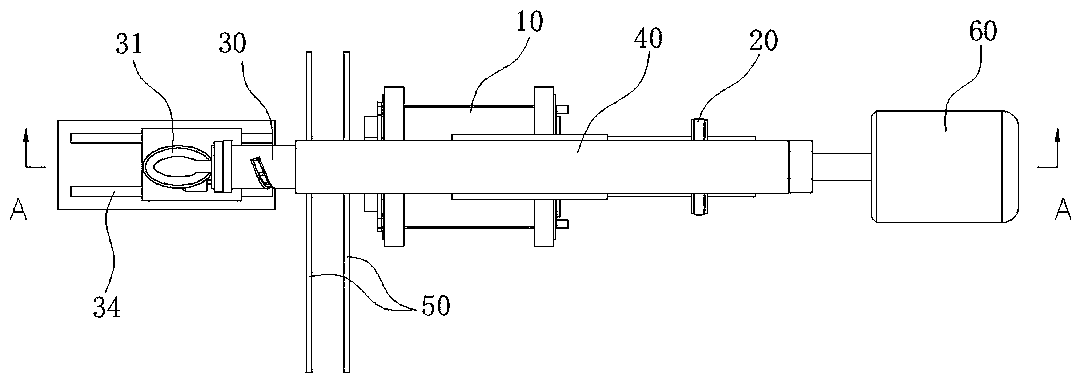

[0026] Such as Figure 1-4 As shown, a cylinder liner centrifugal casting system includes a casting unit and a centrifugal unit. The centrifugal unit includes a cylindrical mold body 10 rotatably arranged along a horizontal axis. The first end of the cylindrical mold body 10 is provided with a first end plate 11. The second end of the cylindrical mold body 10 is provided with a second end plate 12, and the center of the second end plate 12 is provided with a casting channel, and the casting unit is located outside the casting channel, and the casting unit is used for casting The liquid is introduced into the interior of the cylindrical mold body 10, and the casting unit is movable along the axial direction of the cylindrical mold body 10; The inside of the mold body 10 is ejected, and a cylinder liner exporting device 50 is provided below the outer side of the casting channel. The cylinder liner exporting device 50 is used to guide and collect the ejected cylinder liners 1 . ...

Embodiment 2

[0037] Based on the above-mentioned embodiment 1, this embodiment proposes a centrifugal casting process for a cylinder liner 1, which includes the following steps:

[0038] Step 1: Casting liquid smelting, adding raw materials to an intermediate frequency electric furnace for melting and slag removal to obtain casting liquid;

[0039] Step 2: Prepare the centrifugal casting machine, clean the inner wall of the centrifugal casting machine, spray the coating, and preheat the mold;

[0040] Step 3: Move the sprue to the sprue of the centrifugal casting machine;

[0041] Step 4: Casting, start the centrifugal casting machine, use the ladle to pour the pouring liquid into the sprue, and the pouring liquid flows into the mold through the sprue;

[0042] Step 5: Demoulding, after the casting is cooled, take the casting out of the mold, and the cylinder liner 1 is casted;

[0043] In described step 5, the concrete method of demoulding is:

[0044] 1) The driving claw 14 of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com