Grinding Pads and Grinding Devices

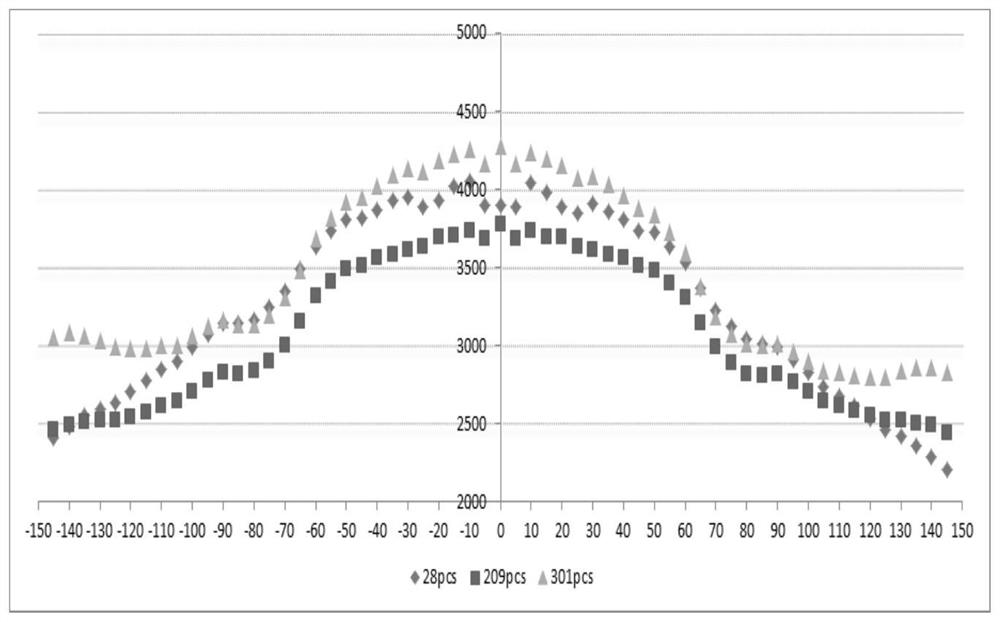

A technology of grinding pads and grinding surfaces, which is applied to grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of large grinding volume, poor flatness, and small grinding volume of wafer perimeter, so as to reduce the grinding volume and improve the flatness. , the effect of reducing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

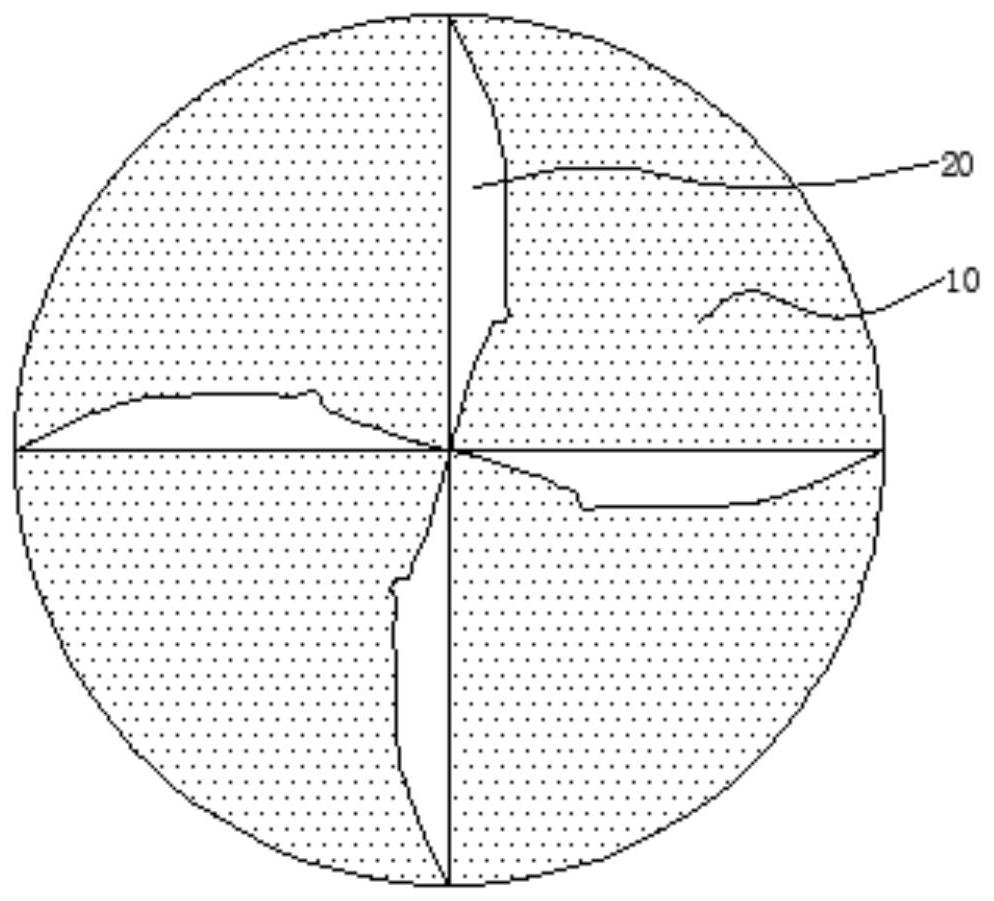

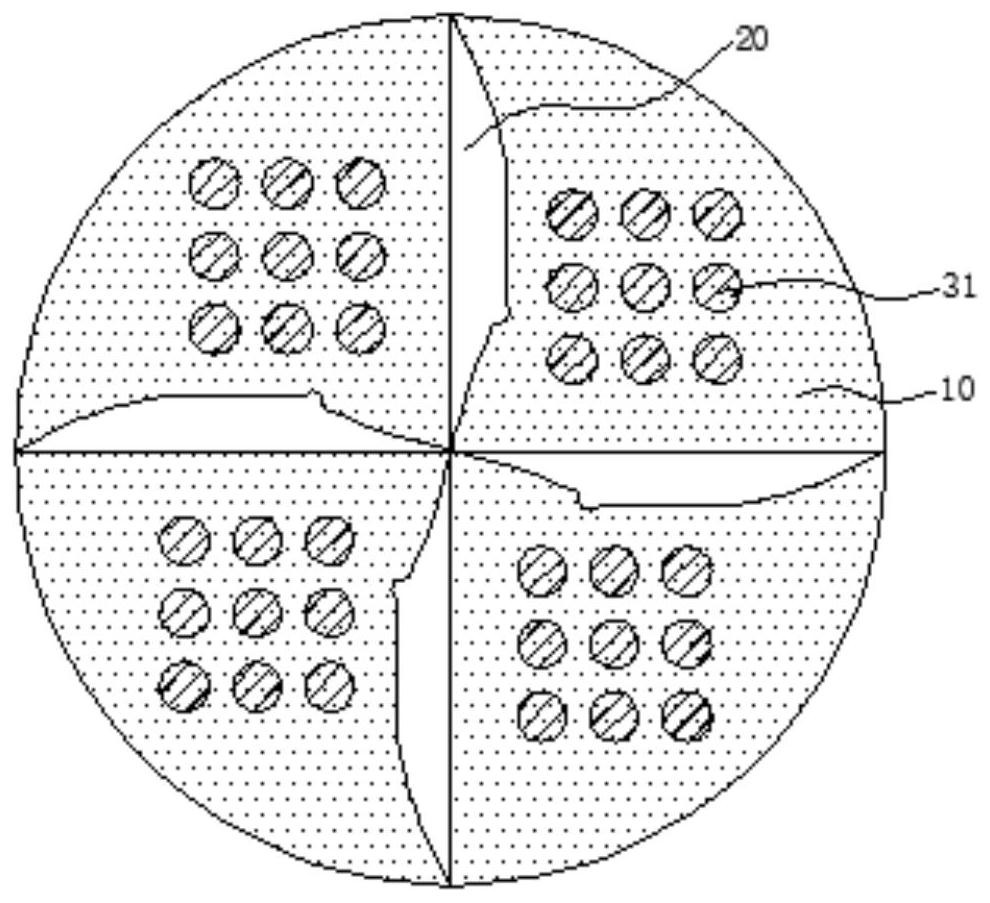

[0030] Based on the above studies, the embodiments of the present invention provide a polishing pad and a polishing device. The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. It should be noted that the drawings are all in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0031] Embodiments of the present invention provide a grinding pad, comprising:

[0032] a plate-shaped pad body with one side being a grinding surface and the other being a support surface; and a plurality of openings, each of which is recessed from the grinding surface toward the support surface, the openings being formed in the pad body The thickness direction of the pad can be a blind hole or a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com