Mounting workbench for pump part machining

A technology for parts and workbenches, applied in the field of workbenches, can solve the problem of not being able to absorb shock and buffer, and achieve the effect of improving stability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

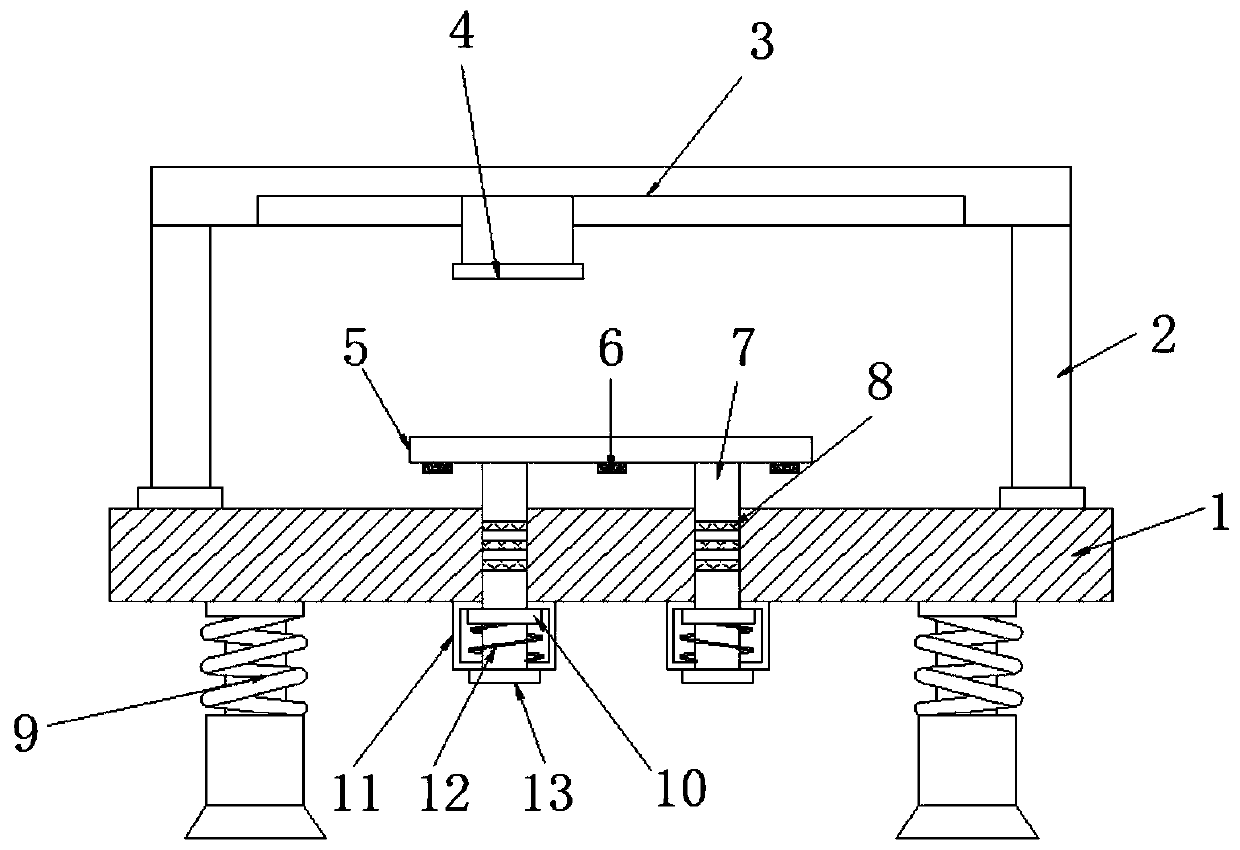

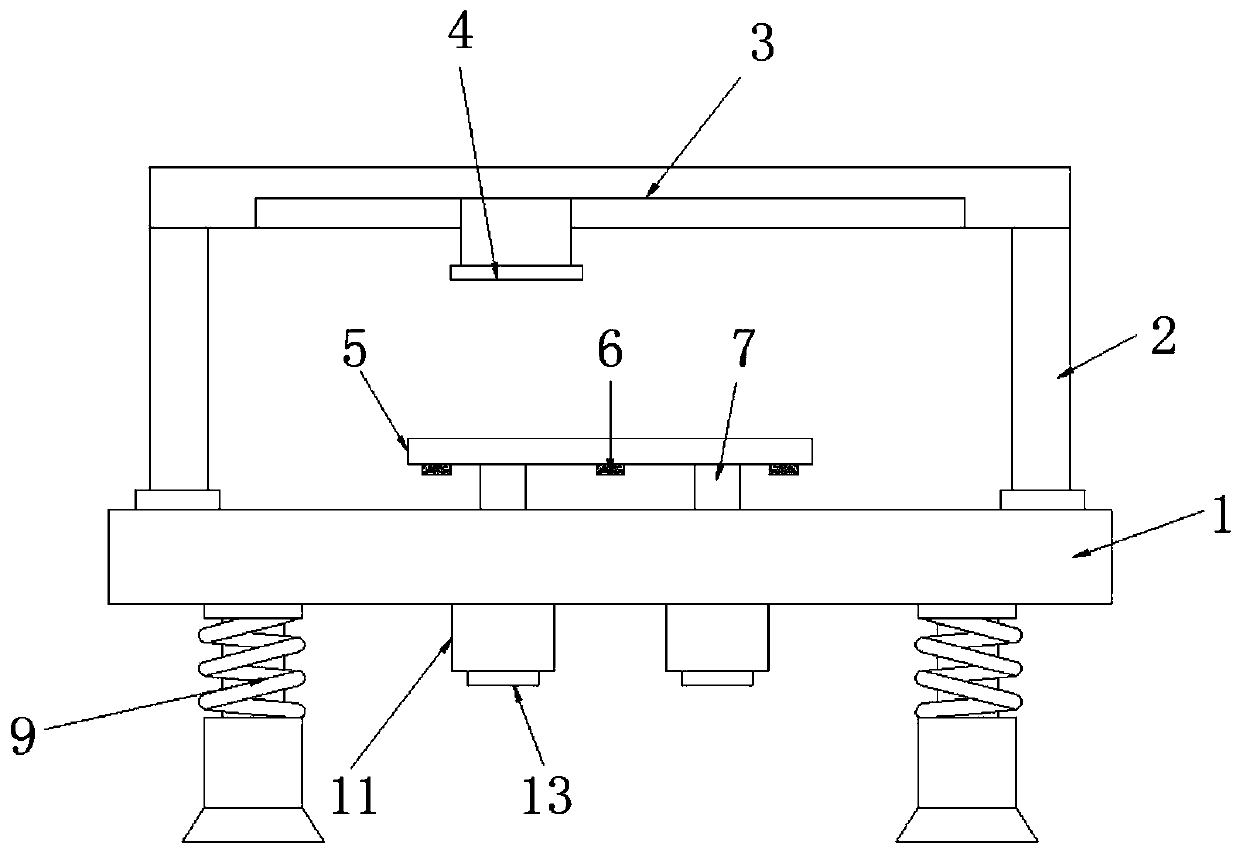

[0023] refer to figure 1 and figure 2 , an installation workbench for pump parts processing, including a base 1, two symmetrically distributed sockets are opened at the center of the outer wall of the top of the base 1, and a movable rod 7 is movably inserted in the socket, and the movable rod 7 There are a pair of equidistant annular grooves on the outer wall of the circumference, and a damping ring 8 is embedded in the annular groove, and the outer wall of the damping ring 8 is attached to the inner wall of the socket, and the same installation panel 5 is fixed on the top of the two movable rods 7. Two limit frames 11 corresponding to the movable rod 7 are fixed on the outer wall of the bottom of the table 1, and the bottom outer wall of the movable rod 7 passes through the limit frame 11 and is fixed with a fixed ring 13, and the outer wall of the movable rod 7 bottom is fixed with a limit ring. 10, and a spring 12 is fixed inside the limiting frame 11, and the spring 12 ...

Embodiment 2

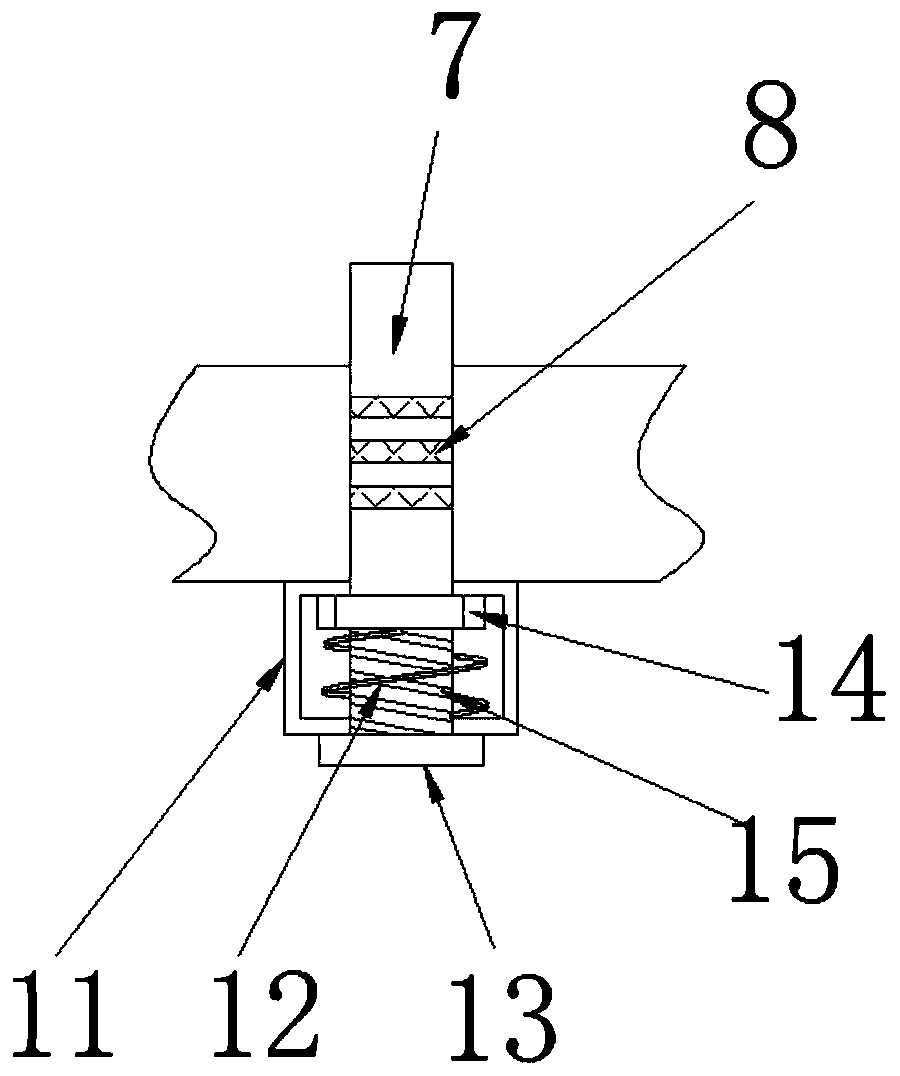

[0027] refer to image 3 , a kind of installation workbench for processing parts and components of a pump. The difference between this embodiment and Embodiment 1 is that there are threads 15 on the outer wall of the circumference of the bottom end of the movable rod 7, and the limit ring 10 is replaced by a collar 14, and the collar 14 The thread is sleeved on the thread 15 of the movable rod 7 .

[0028] The working principle of this embodiment: the collar 14 can compress the spring 12 when rotating on the movable rod 7, so as to realize the adjustment of the initial type variable of the spring 12, and then flexibly adjust the initial damping intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com