Flexible Plastic Cutting Machine

A cutting machine and cutting mechanism technology, applied in the field of machinery, can solve the problems of complex structure of the cutting machine, increase the cost of the cutting machine and the complexity of adjustment and use, and achieve the effects of simple and convenient adjustment, low cost and consistency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

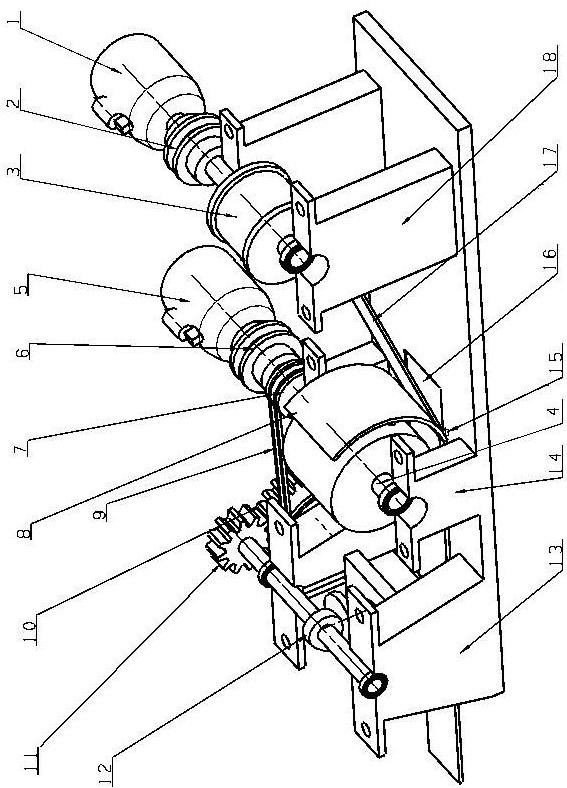

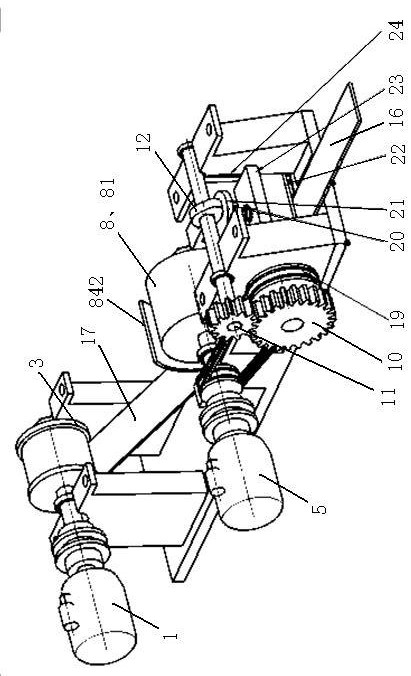

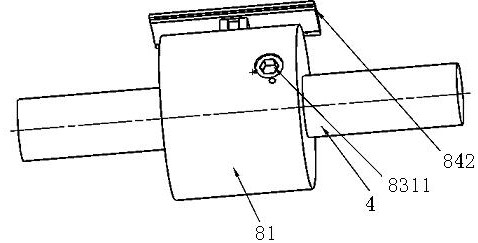

[0031] Such as figure 1 and figure 2 As shown, in this embodiment, the plastic material cutting machine includes a brake motor 1, a plastic material wheel 3, a transmission shaft 4, a main motor 5, a small pulley 7, a friction wheel 8, a belt 9, a large gear 10, and a pinion 11 , cam 12, elastic button 15, large pulley 19 and cutting mechanism.

[0032] The main motor 5 is connected with the same rotating shaft 4 where the small pulley 7 and the friction wheel 8 are located through the second coupling 6 . The friction wheel 8 and the small pulley 7 are driven by the main motor 5 to rotate synchronously. Small pulley 7 is connected with big pulley 19 by belt 9 transmission belts. Large belt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap