Prefabricated steel structure steel column decoration structure and method

A technology for decorative structures and steel structures, applied in building construction, covering/lining, construction, etc., can solve the problems of easy corrosion and rust, difficult to install, etc., and achieve the effect of prolonging service life, reducing costs, and simple decoration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

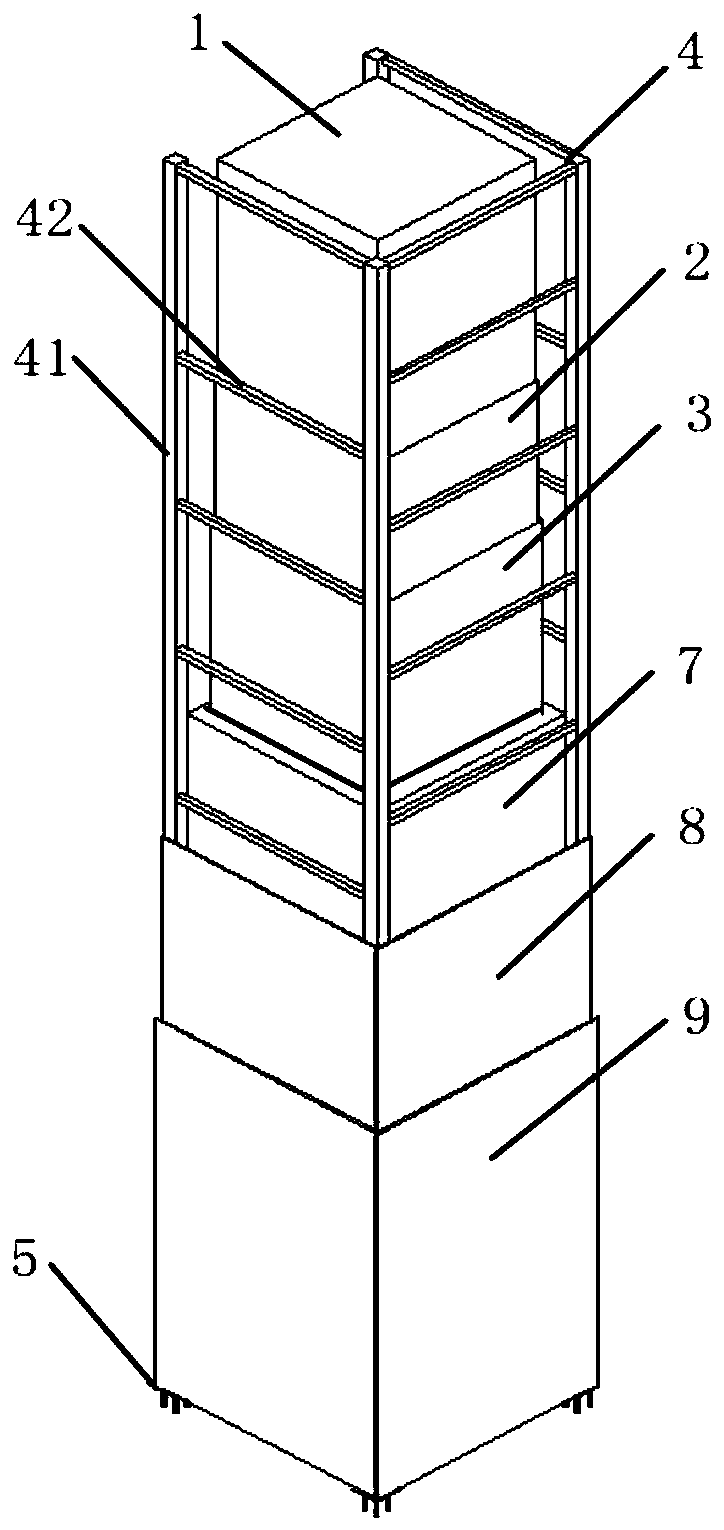

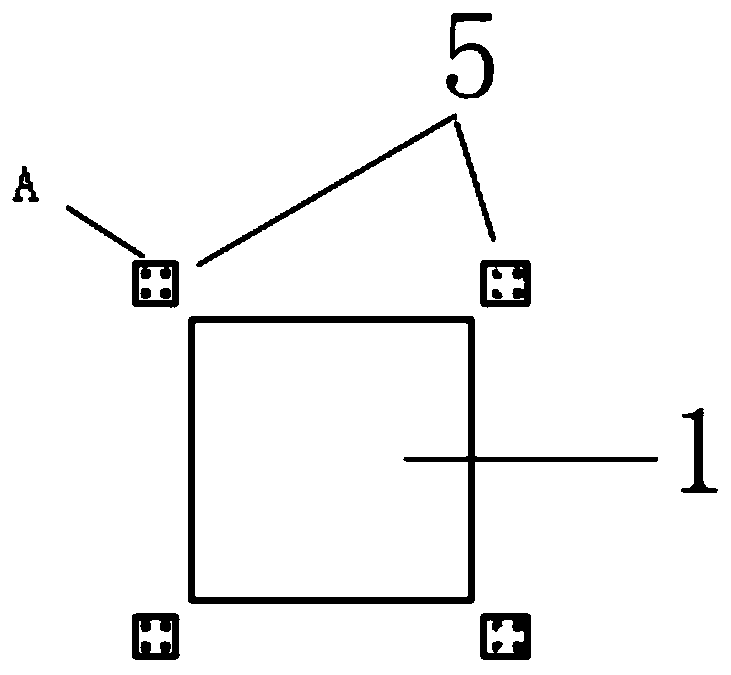

[0036] figure 1 It shows an assembled steel structure steel column decoration structure, the surface of the steel column 1 is stacked with an anticorrosion layer 2 and a fireproof layer 3 . The steel column 1 is covered with a fixed bracket 4, and the two ends of the fixed bracket 4 are welded to the steel beam respectively, and an anti-corrosion coating is provided on the welding point. The thickness of the fireproof layer 3 is 1.5cm-2.5cm.

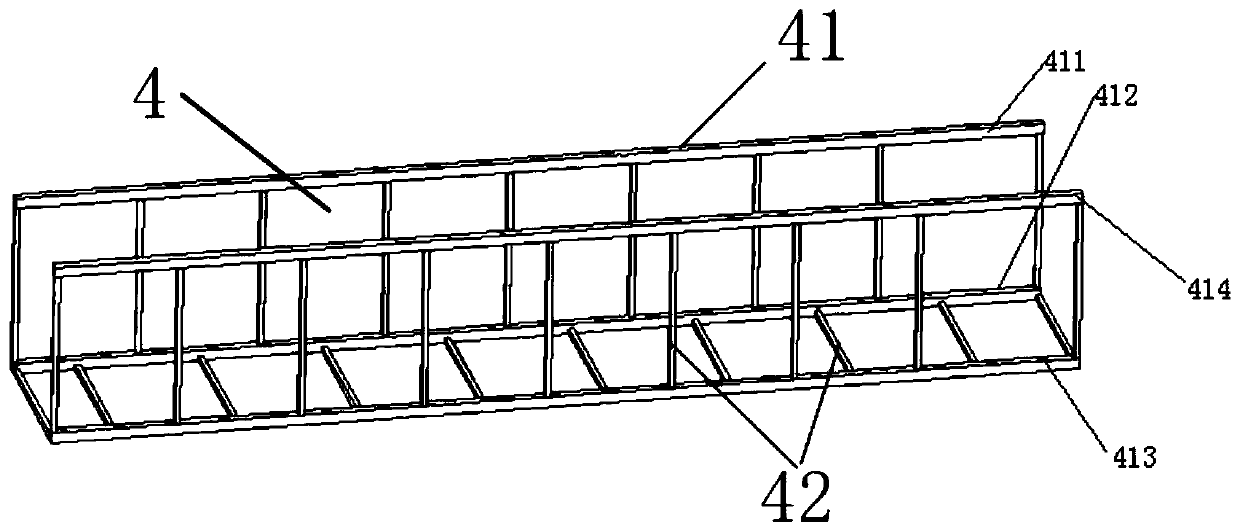

[0037] see figure 2 , the fixed bracket 4 includes: the first facade, the second facade and the third facade, the first and the third facade are perpendicular to the second facade respectively, and are respectively connected with the opposite sides of the second facade, which is " 匚" type. Setting the fixed support 4 according to this shape is beneficial to save raw materials and play a decorative and protective role.

[0038] The fixed bracket 4 includes: a plurality of horizontal keels 42 and 4 vertical keels 41 . The vertical kee...

Embodiment 2

[0044] The difference with embodiment 1 is:

[0045] The fixed bracket 4 is made of a galvanized square tube.

Embodiment 3

[0047] The difference with embodiment 1 is:

[0048] The cross-sectional dimension of the vertical keel 41 is (30-50)*(30-50)mm, and the cross-sectional dimension of the transverse keel 42 is 25*25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com