A device for automatically spraying insulating paint on metal wires of electronic components

A metal wire, automatic spraying technology, applied to electrical components, conductor/cable insulation, cable/conductor manufacturing, etc., can solve the problem of inability to ensure the uniformity and efficiency of the conductor surface paint surface, the upper limit of the insulating paint temperature resistance, and the inability to meet and other problems to achieve the effect of avoiding single-sided spraying, solving the problem of high temperature resistance, and satisfying the replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

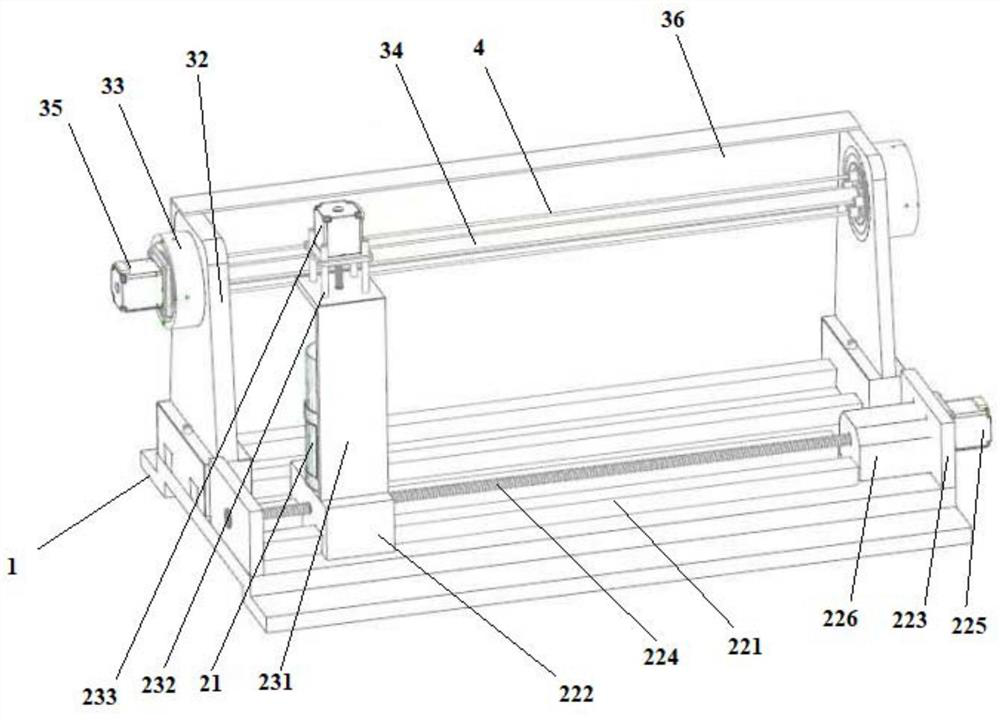

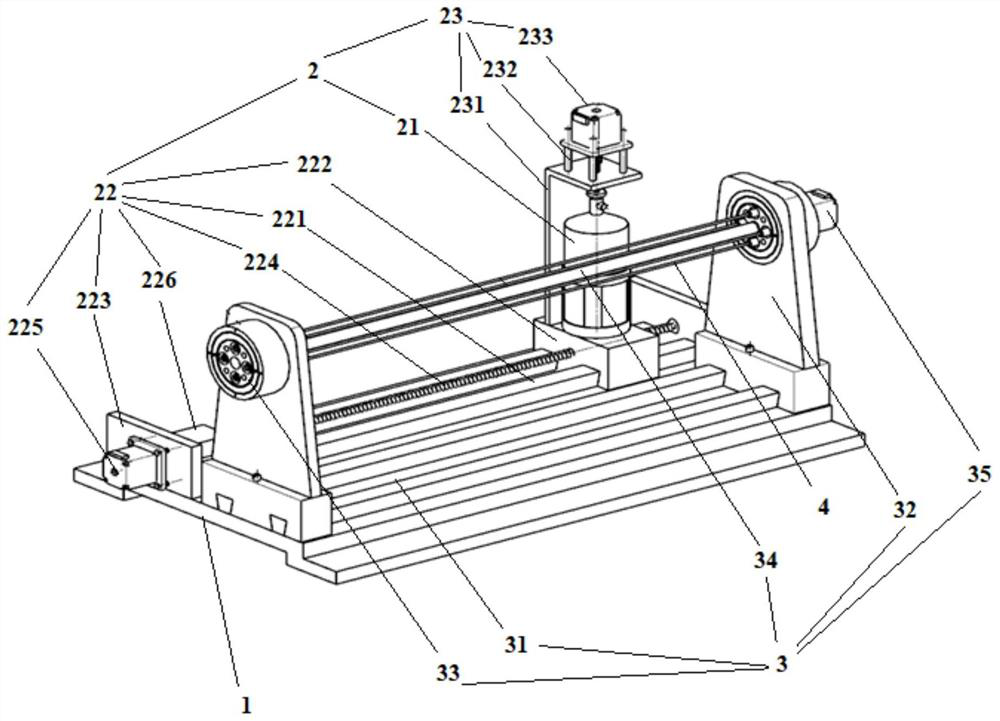

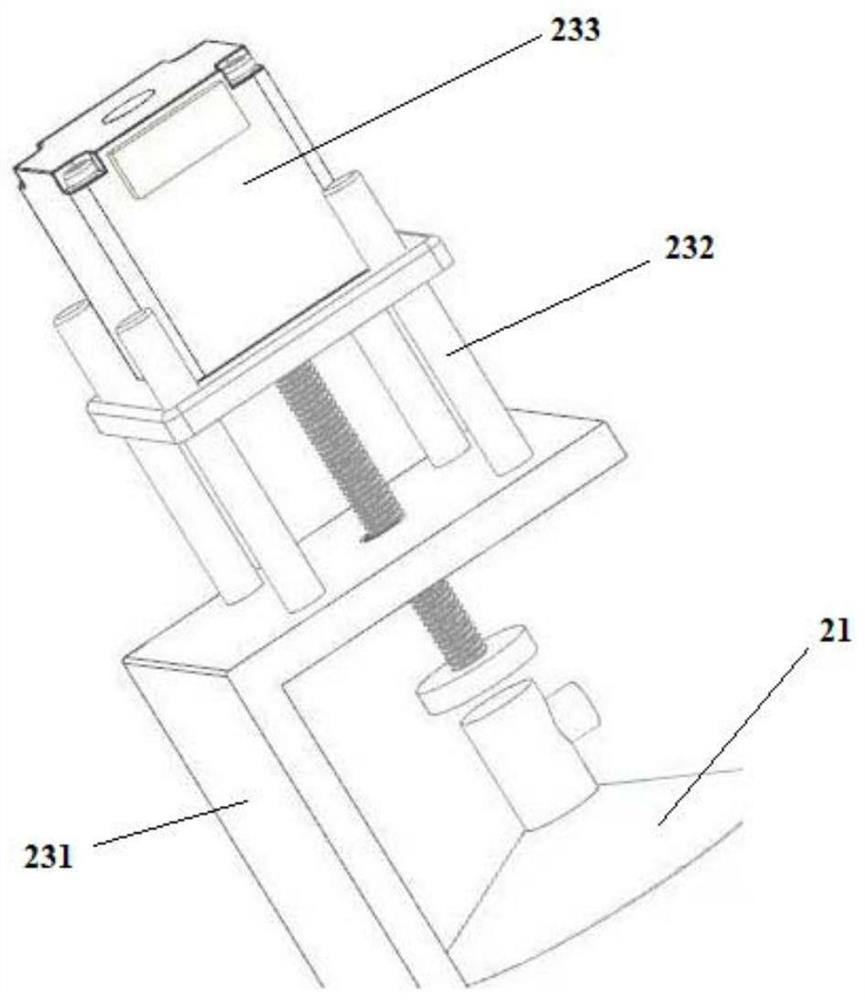

[0041]The present embodiment provides a kind of device that automatically sprays insulating varnish to the metal wire of electronic component, comprises the paint spraying mechanism 2 that is located on the base 1 and the metal wire installation mechanism 3; The paint spray can displacement control unit 22 and the spray paint volume adjustment unit 23 that can control the spray paint can 21 switch above the paint spray can 21; the spray paint can displacement control unit 22 includes two parallel guide rails 221 fixed on the base 1, running through The displacement block 222 on the guide rail 221 that can move along the guide rail 221, the fixed plate 223 that is vertically fixed on the base 1 and is positioned at the two ends of the guide rail 221 parallel to each other, the penetration displacement block 222 that is located between the two fixed plates 223 and is connected with The screw rod 224 parallel to the guide rail 221 and the first motor 225 located at one end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com