Real-time correction system for serial image data training of CMOS image sensor

An image sensor, image data technology, applied in image communication, TV system parts, color TV parts and other directions, can solve problems such as data sampling errors, changes in the relative position of serial data jumping edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

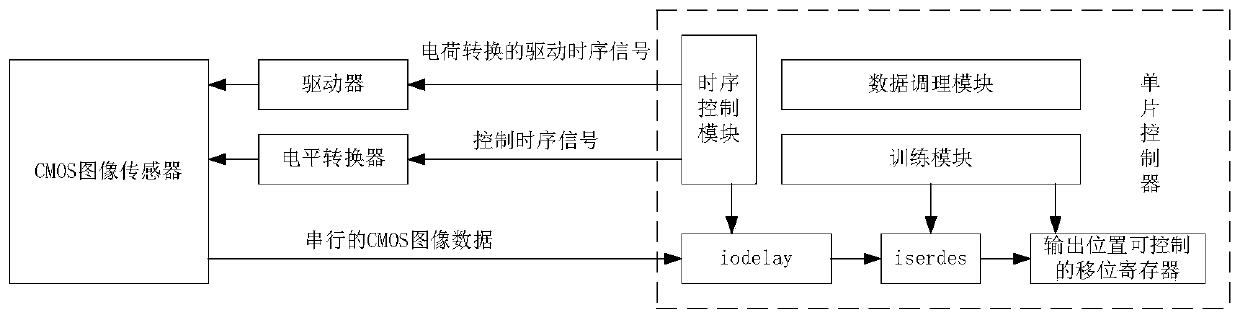

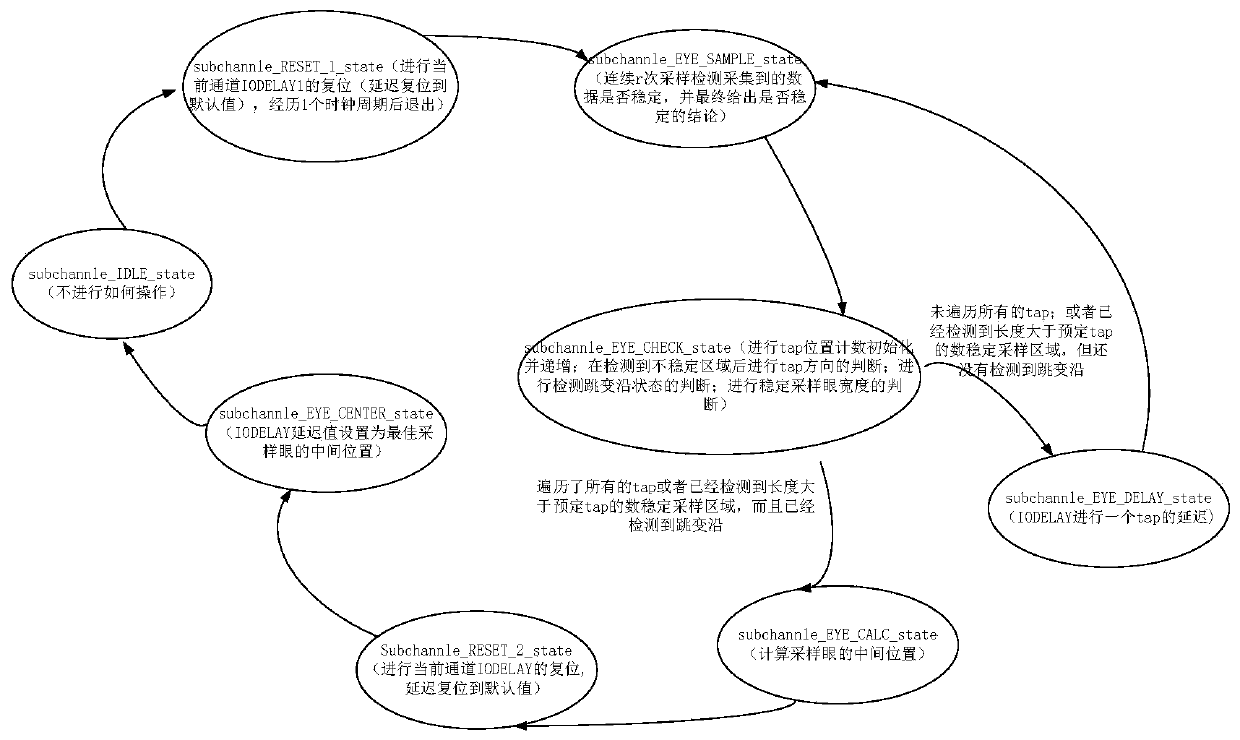

[0014] Specific implementation mode 1. Combination Figure 1 to Figure 5 Describe this embodiment, the serial image data training and real-time correction system of CMOS image sensor, comprise CMOS image sensor, driver, level shifter and monolithic controller; The monolithic controller includes timing control module, data conditioning module module, training module, iodelay, iserdes, and shift register with controllable output position; the timing control module in the single-chip controller outputs the driving timing signal and control timing signal for charge transfer, after passing through the driver and level converter respectively, Send it into the CMOS image sensor; the serial CMOS image data output by the CMOS image sensor, through the iodelay, iserdes and output position controllable shift register controlled by the training module, is converted into stable parallel data whose output effective data position is determined, and then After the data conditioning module, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com