Ultrasonic detection-based separation system for media with different specific gravity

A separation system and ultrasonic technology, used in immiscible liquid separation, filtration separation, specific gravity measurement, etc., can solve the problems of inability to determine the liquid level limit of different media, inability to detect the pressure at the end of the outlet pipe, and difficulty in obtaining correct results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

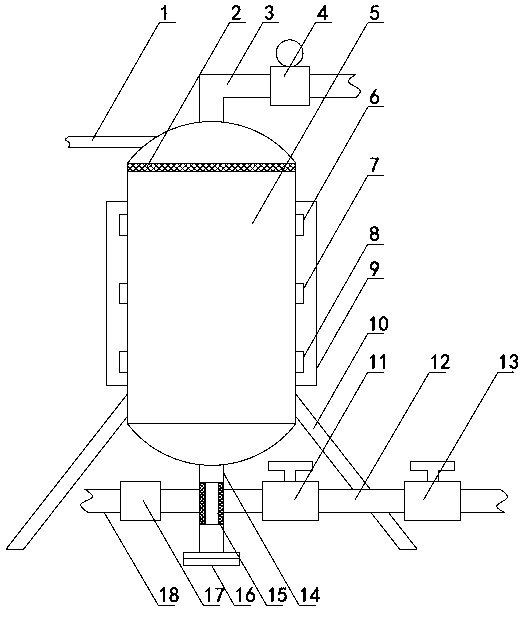

[0023] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0024] Such as figure 1 As shown, a system for separating media with different specific gravity based on ultrasonic detection includes a liquid storage tank 5, and a plurality of feet 10 are evenly fixed on the lower circumference of the liquid storage tank 5, and the liquid storage tank 5 is always kept vertical by the feet 10 state. A medium input pipeline 1 is arranged on the side of the tank top of the liquid storage tank 5, and the medium is conveyed into the liquid storage tank 5 through the medium input pipeline 1, and a liquid inlet filter screen 2 is arranged at the inner upper end of the liquid storage tank 5, through which The liquid inlet filter screen 2 performs primary filtration on the medium entering the liquid storage tank 5 . A light medium return pipeline 3 is led out from the top of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com