Automatic intelligent processing equipment for casting and forming castings

A casting forming and processing equipment technology, applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to control the discharge speed of molten iron and affect the quality of castings, achieve small torsional force, improve casting quality, and reduce safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

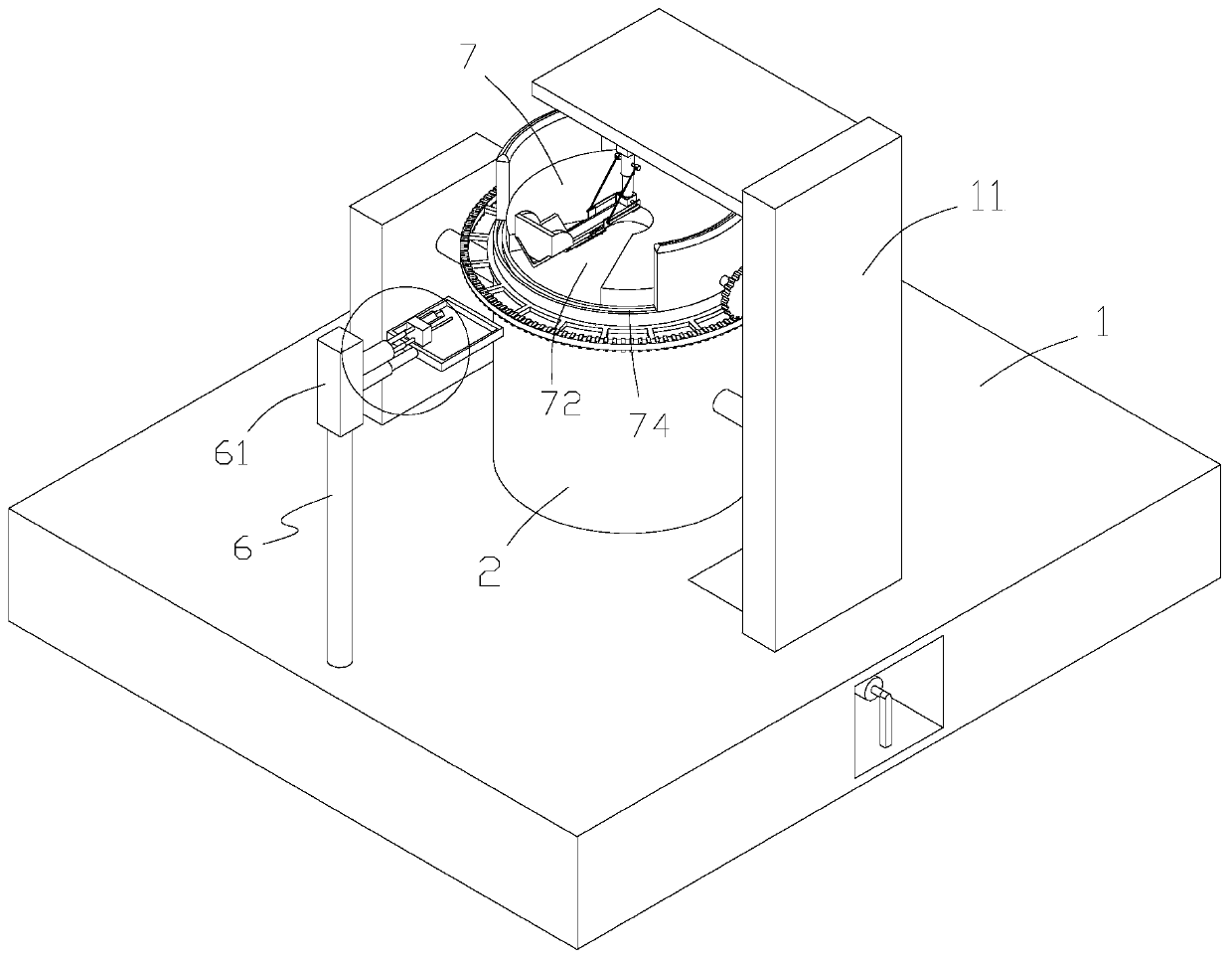

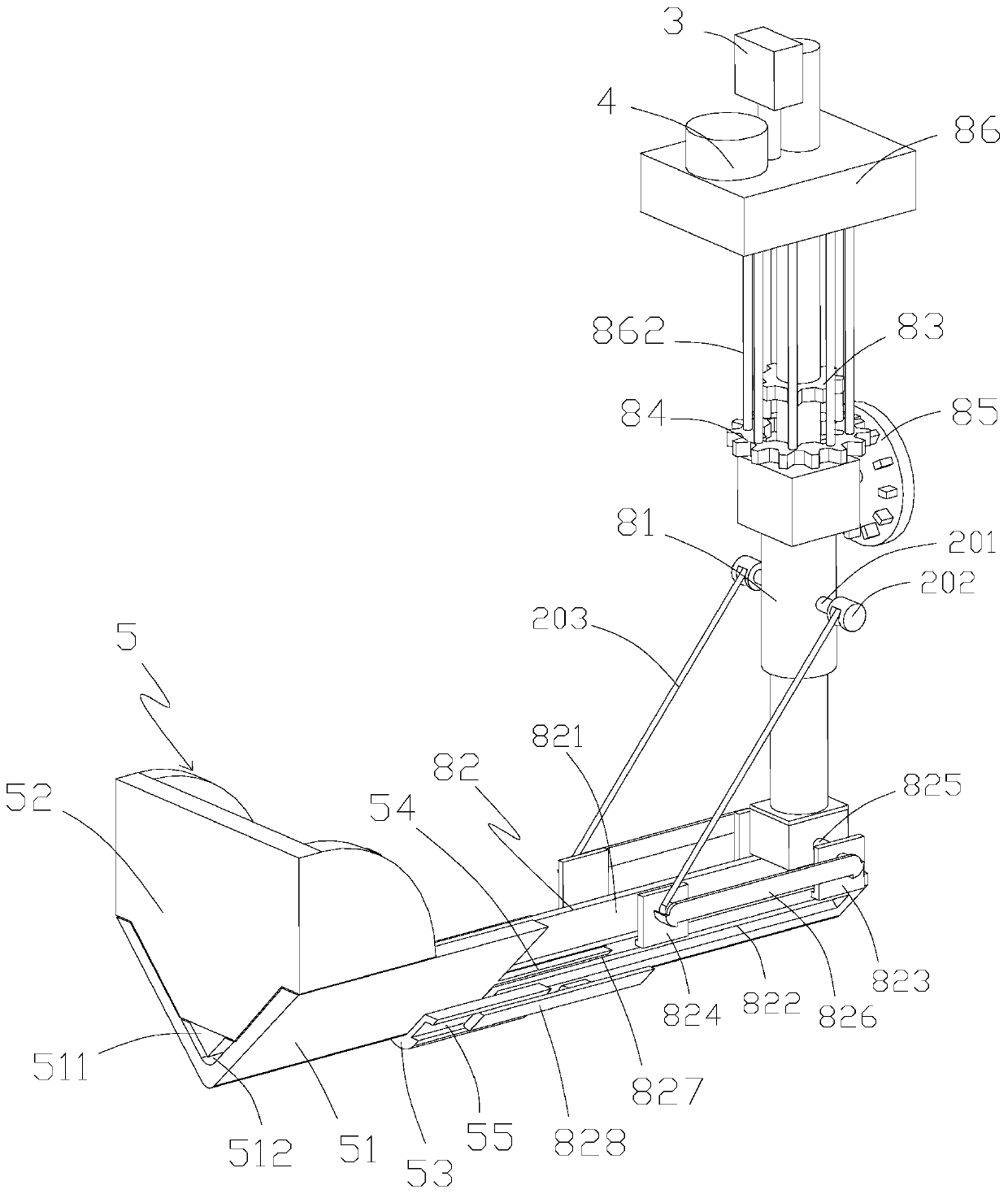

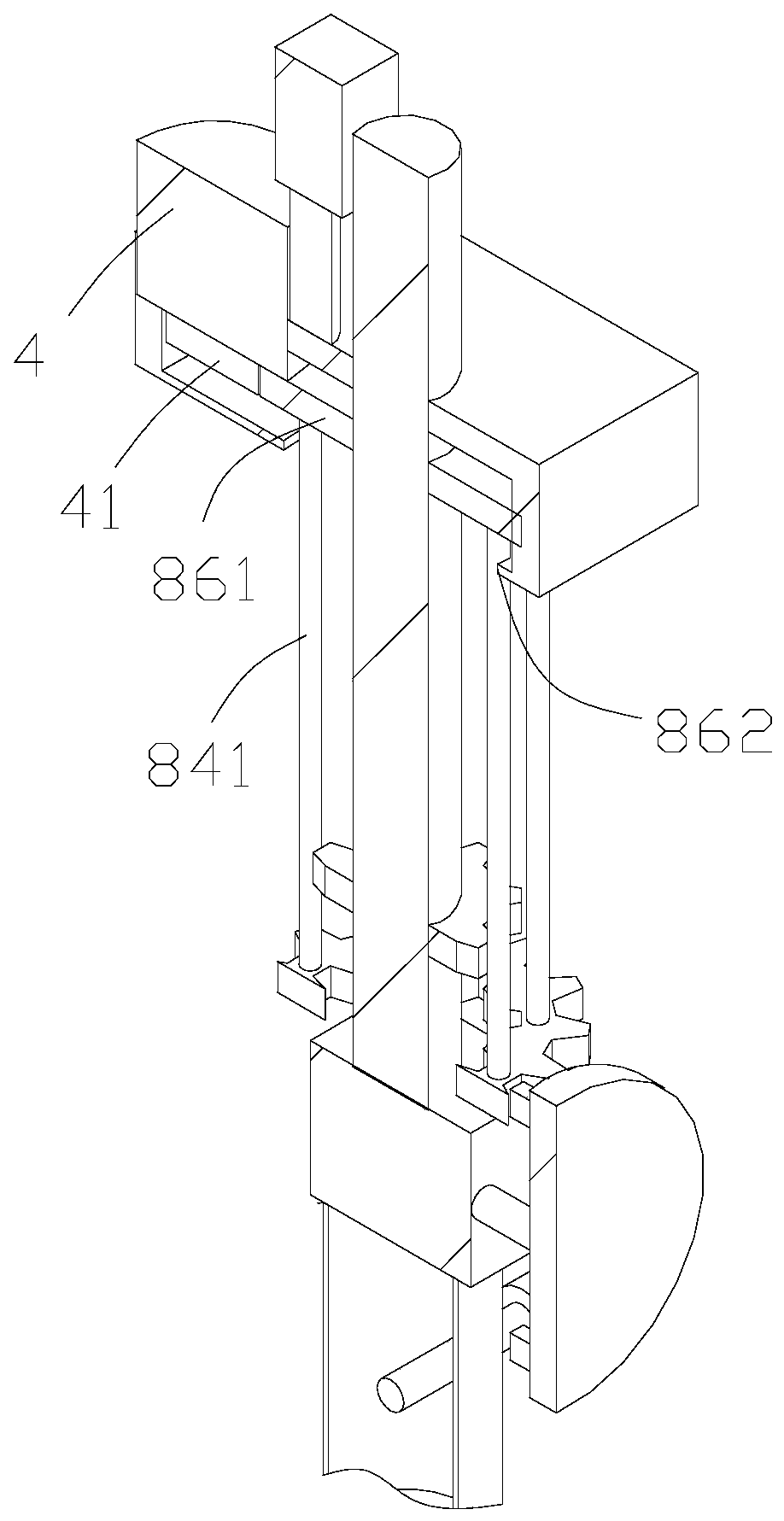

[0027] Such as Figure 1-7 As shown, an automatic intelligent processing equipment for casting casting and forming, including a base 1, on which two brackets 11 are arranged; a casting barrel 2, and two connecting arms 21 are stacked on its outer wall, and the connecting arms 21 are rotatable is installed on the support 11; the driving device is used to drive the casting ladle 2 to turn over relative to the support; the cleaning device is used to clean the solidification on the upper layer of the molten iron in the ladle 2, including the ability to move up and down to penetrate To the cleaning part in the casting barrel, the displacement drive part 3 for driving the cleaning part to move up and down, the rotary drive part 4 for driving the cleaning part to rotate, the material storage part 5 matched with the cleaning part and the storage part A waste material discharge part 6 that matches the material parts; a casting nozzle 22 is formed by extending the side wall of the casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com