A pipe automatic feeding device

A technology of automatic feeding and feeding device, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of reducing work efficiency, low feeding efficiency, increasing production cost, etc., to improve work efficiency, The high degree of automation and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

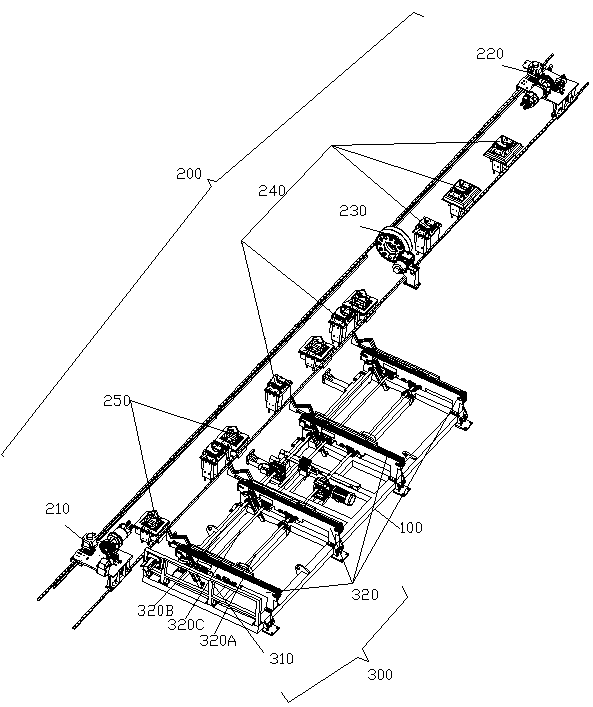

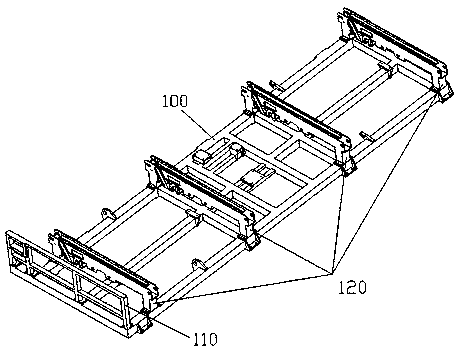

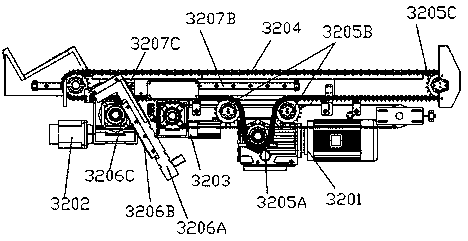

[0034] See Figure 1 to Figure 10, the present invention has a first frame 100, the first frame 100 is provided with a feeding station 300, and the side of the first frame 100 is provided with a feeder for receiving the pipe material on the feeding station 300 and feeding Work station 200, the feeding station 300 is provided with a plurality of feeding devices 320 for pipe material feeding in parallel, and the feeding device 320 includes a plurality of transmission brackets 120 parallel and fixedly arranged on the first frame 100 , a plurality of transmission chain belts 3204 for transporting pipes and driven by the first driving motor 3201, and a plurality of feeding racks 3207A driven by the second driving motor 3203 and used for transporting the pipes to the feeding station 200, One end of each feeding frame 3207A close to the feed station 200 is fixedly provided with a supporting frame for supporting the pipe on the transmission chain belt 3204, and each feeding frame 3207...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com