A ceramic tile gap cleaning machine for architectural beautification

A technology for cleaning machines and ceramic tiles, which is applied in the directions of grinding machine parts, manufacturing tools, grinding machines, etc., can solve the problems that construction workers spend a long time, and construction workers are prone to leg numbness, etc., to save time and avoid leg numbness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

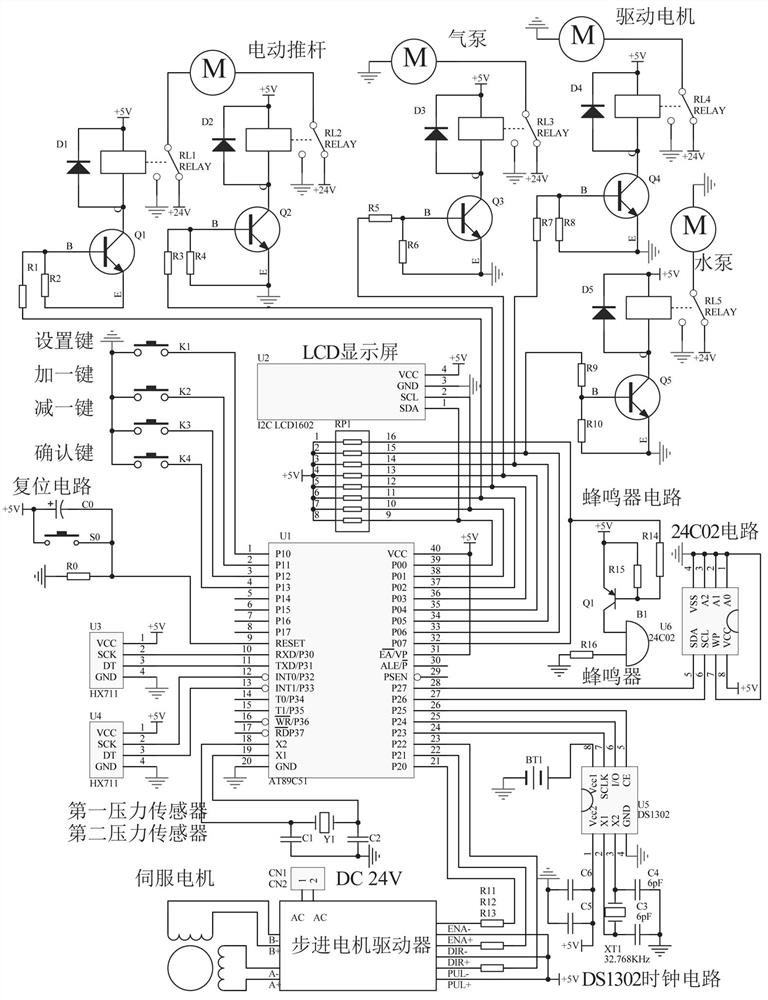

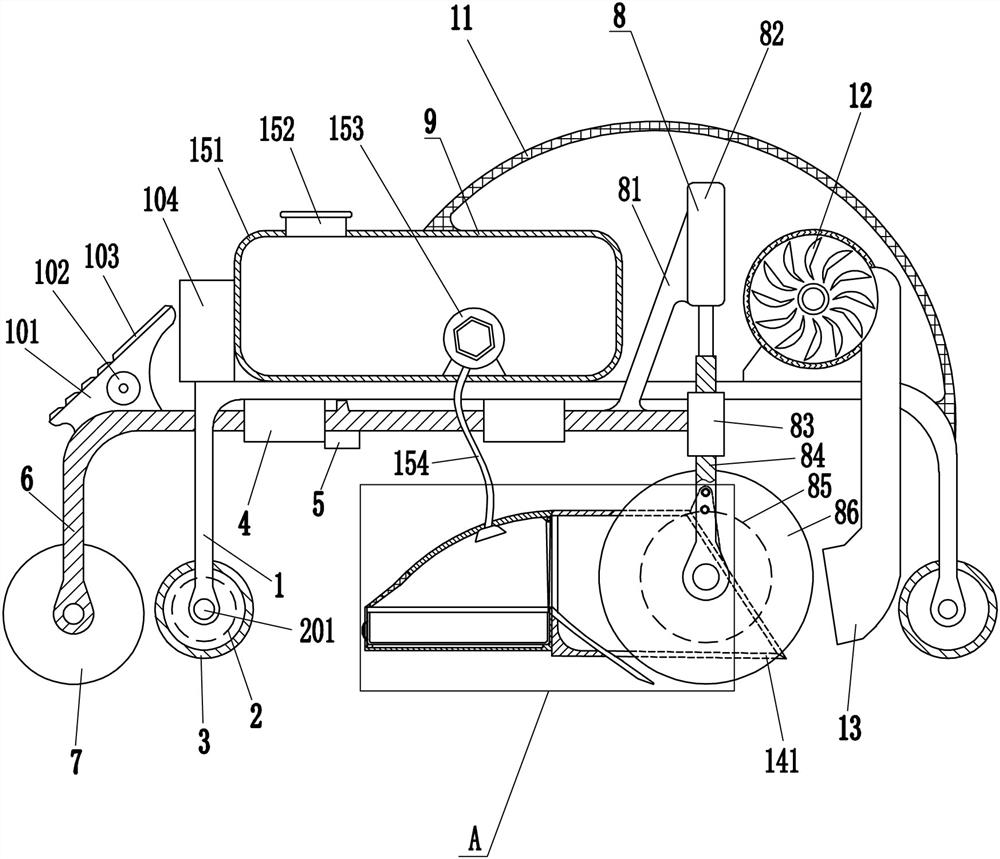

[0022] A tile gap cleaning machine for building beautification, see figure 1 , including bracket 1, servo motor 2, rotating shaft 201, roller 3, guide sleeve 4, first pressure sensor 5, guide rod 6, guide disc 7, cleaning device 8, protective net 11, air pump 12 and nozzle 13, bracket 1. The servo motor 2 is installed on the rear side. The bracket 1 is connected to the servo motor 2 by means of bolt connection. The left and right parts of the bracket 1 are both rotatably installed with a rotating shaft 201, and the left rotating shaft 201 is connected to the output shaft of the servo motor 2. , the rotating shaft 201 is connected with the servo motor 2 through a shaft coupling, two rollers 3 are installed on the rotating shaft 201, two guide sleeves 4 are installed on the inner top of the bracket 1, the bracket 1 is connected with the guide sleeve 4 through a bolt connection, and the guide sleeve 4 is provided with a guide rod 6, the bottom end of the guide rod 6 is rotatably ...

Embodiment approach 2

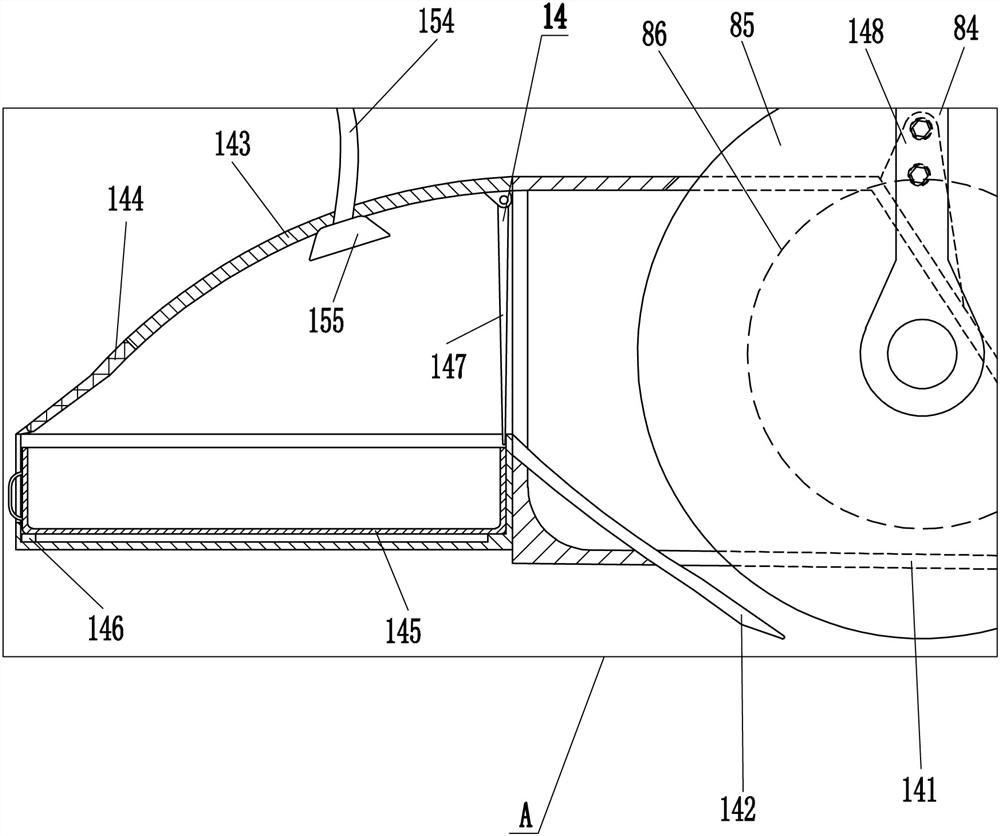

[0028] On the basis of Embodiment 1, see figure 1 and figure 2 , also includes a dust collection device 14, the dust collection device 14 includes a protective frame 141, a sloping plate 142, a special-shaped frame 143, a screen 144, a collection frame 145, a second pressure sensor 146, a swing plate 147 and a connecting plate 148, sliding The lower part of the rod 84 is connected with a connecting plate 148, the connecting plate 148 is connected with a protective frame 141, the protective frame 141 is connected with a slanting plate 142, the protective frame 141 is connected with the slanting plate 142 by welding, and the special-shaped frame 143 is fixed on the protective frame 141. Frame 141 left side, special-shaped frame 143 is connected with protective frame 141 by the mode of bolt connection, and special-shaped frame 143 tops are embedded with retaining net 144, and collecting frame 145 is placed in special-shaped frame 143, and special-shaped frame 143 inner bottom is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com