A Remediation System for Groundwater Contaminated by Ammonia Nitrogen-Inorganic Phosphorus

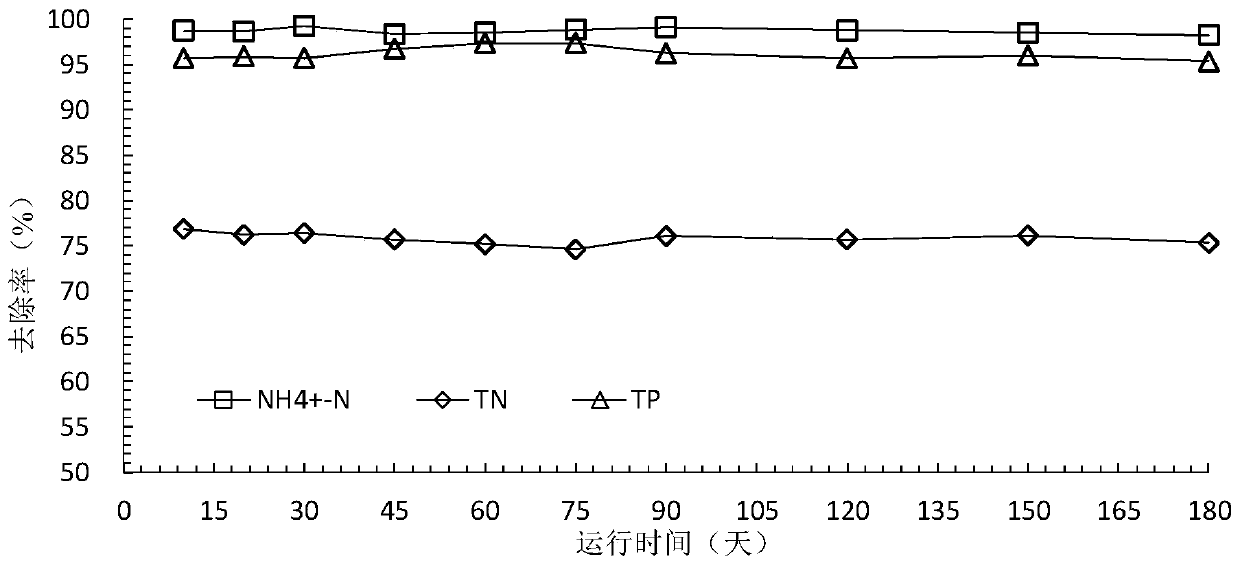

A technology for complex pollution and restoration systems, applied in the treatment of polluted groundwater/leachate, water pollutants, and multi-stage treatment of water/sewage, etc., can solve the problems of increasing the cost of water treatment per ton, threats to human health, death, etc. Achieve the effect of reducing the frequency of gas flushing and operation and maintenance costs, avoiding premature saturation failure, and reducing the load of influent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of the above-mentioned composite adsorption material includes: crushing zeolite, bentonite and coal cinder to 200-500 mesh respectively; weighing the crushed raw materials according to the above weight ratio and stirring and mixing; putting the mixture into a granulator to make 2 ~4mm particles; drying at 50-60°C for 5-10 hours; roasting at 500-700°C for 3-4 hours.

[0073] Further, the length:width:height ratio of the anaerobic pool is 1~3:1~1.5:4~5;

[0074] The length: width: height ratio of the anoxic pool is 1~3:1~1.5:4~5;

[0075] The length: width: height ratio of the aerobic pool is 1~3:1~1.5:4~5;

[0076] The length: width: height ratio of the sedimentation tank is 1~3:1~1.5:4~5;

[0077] The length:width:height ratio of the adsorption pool is 1~3:1~1.5:4~5.

[0078] Each pool body is in the shape of a cuboid, which can be a glass reinforced plastic structure, a concrete structure or a steel structure.

[0079] Further, it also includes...

Embodiment 1

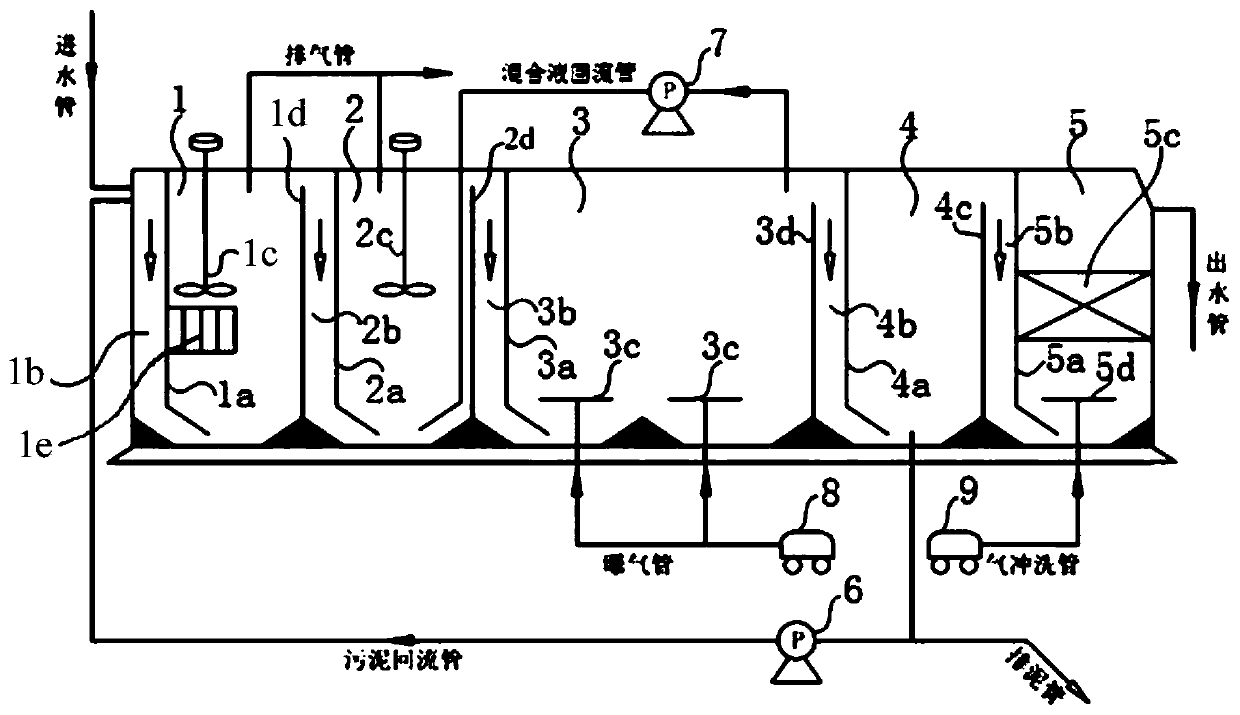

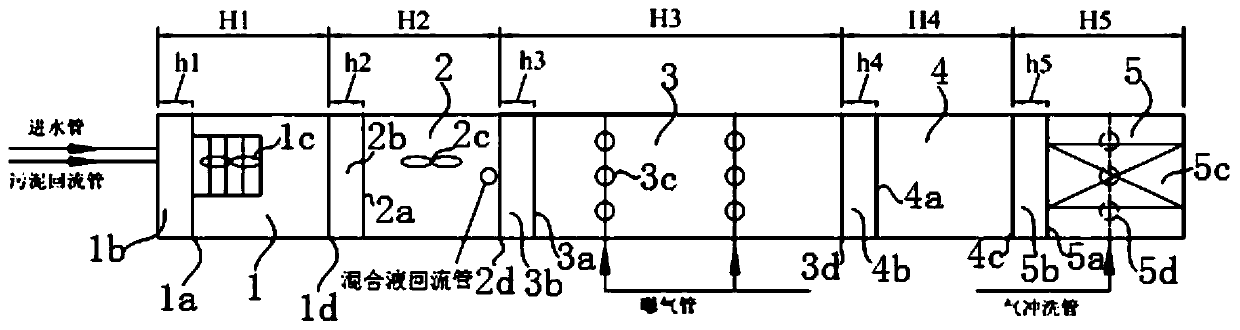

[0107] This embodiment provides a repair system for ammonia nitrogen-inorganic phosphorus compound polluted groundwater, such as figure 1 As shown, it is composed of anaerobic pond 1, anoxic pond 2, aerobic pond 3, sedimentation pond 4 and adsorption pond 5, anaerobic pond 1, anoxic pond 2, aerobic pond 3, sedimentation pond 4 and adsorption pond 5 The hydraulic retention time ratio is 1:1:1:1:1, and the volume ratio is 1:1:1:1:1; each pool is in the form of a cuboid, with a glass fiber reinforced plastic structure, and the length h1 of the first diversion area is the same as the The ratio of the length H1 of the anaerobic tank is 5:20; the ratio of the length h2 of the second diversion zone to the length H2 of the anoxic tank is 5:20; the length h3 of the third diversion zone is compared to the length h3 of the anoxic tank The ratio of the length H3 of the aerobic tank is 5:20; the ratio of the length h4 of the fourth diversion zone to the length H4 of the sedimentation tank ...

Embodiment 2

[0115] This embodiment provides a repair system for ammonia nitrogen-inorganic phosphorus compound polluted groundwater, such as figure 1 As shown, it is composed of anaerobic pond 1, anoxic pond 2, aerobic pond 3, sedimentation pond 4 and adsorption pond 5, anaerobic pond 1, anoxic pond 2, aerobic pond 3, sedimentation pond 4 and adsorption pond 5 The hydraulic retention time ratio is 1:1:1:1:1, and the volume ratio is 1:1:1:1:1. Each pool body is a rectangular parallelepiped and has a glass fiber reinforced plastic structure. The ratio of the length h1 of the first diversion area to the length H1 of the anaerobic pool is 6:20; The ratio of the length H2 of the third diversion zone is 6:20; the ratio of the length h3 of the third diversion zone to the length H3 of the aerobic tank is 6:20; the length h4 of the fourth diversion zone and the length of the sedimentation tank The ratio of the length H4 is 6:20; the ratio of the length h5 of the fifth diversion area to the length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com