Method for integrally treating coking wastewater

A technology for coking wastewater and biochemical treatment, applied in natural water treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. The effect of complete chain and mature processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

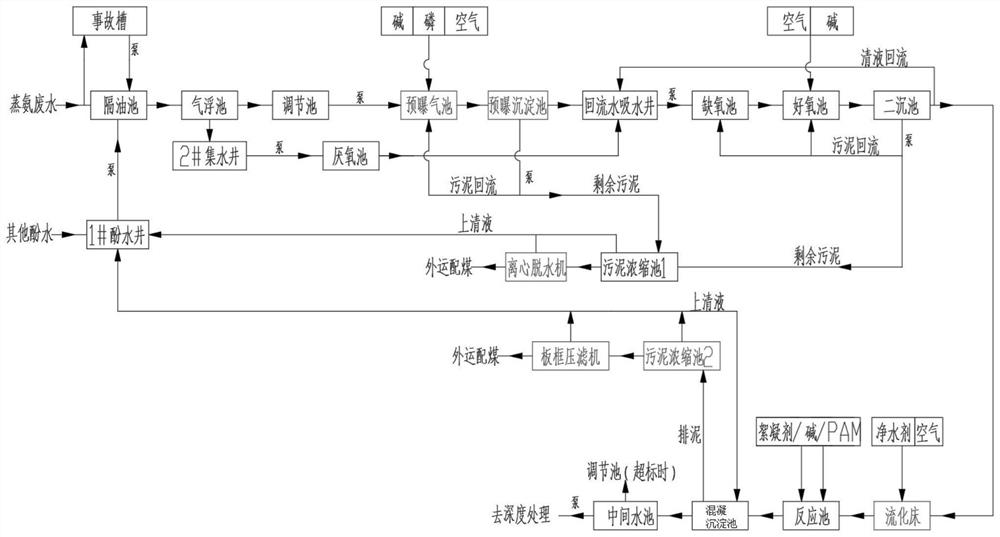

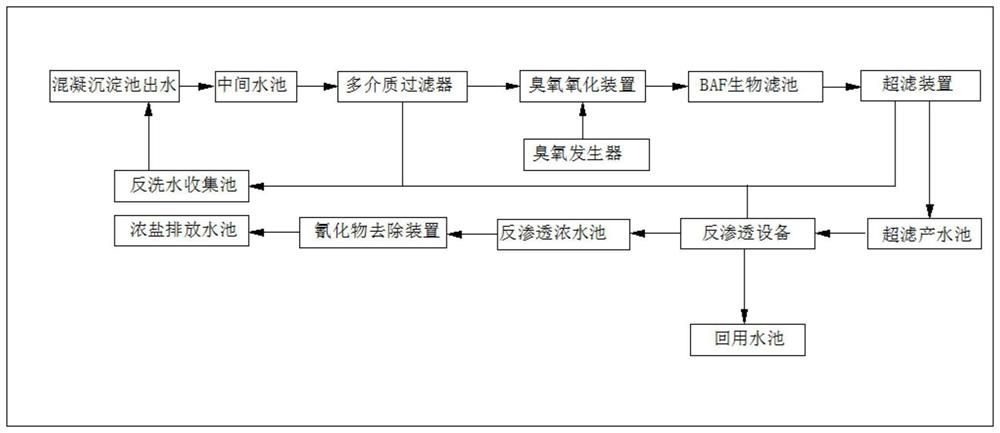

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the present invention, and are all used to explain the content of the present invention within the scope of reasonable changes.

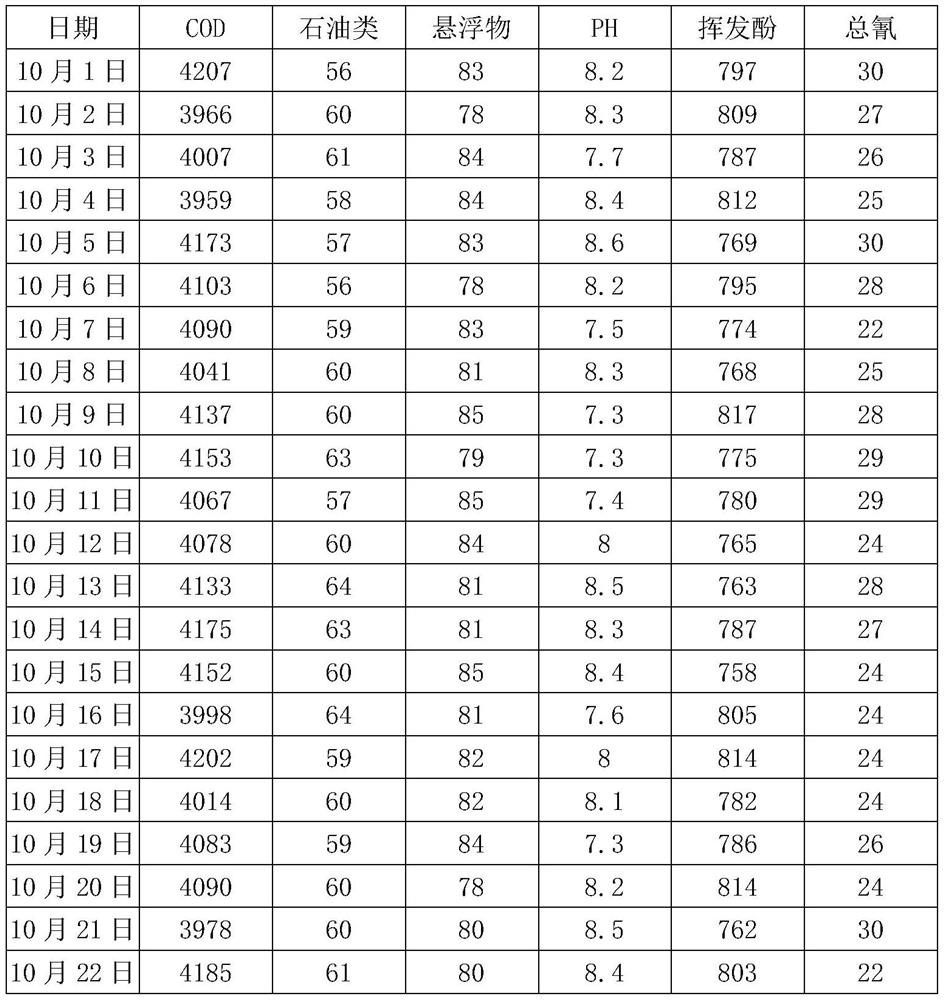

[0027] Through the implementation of the scheme of the invention, the goals of centralized treatment of wastewater in three areas of a certain coking plant with zero dilution and zero external discharge are realized. While reducing labor intensity, the water production index is qualified and stable, reaching the expected design standard, no new water is used for supplementation, all indicators meet relevant policy requirements, and there is no external discharge of waste water. The specific plan is as follows:

[0028] Ammonia distillation waste water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com