A/O type biological aeration capacity-enlarging method for sewage water treatment factory

A technology of biological aerated filter and sewage treatment plant, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., to achieve the effect of less land occupation and water quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

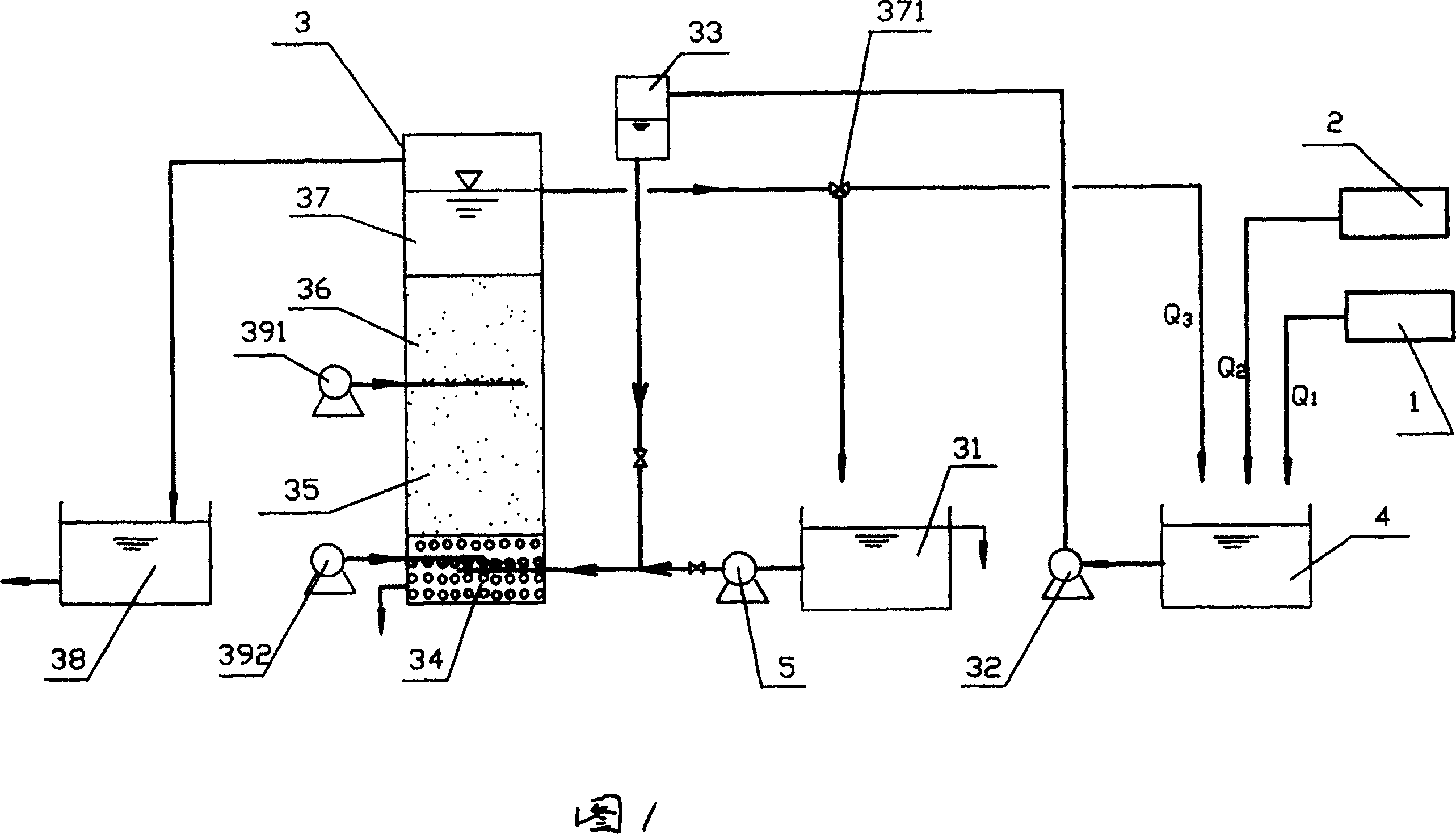

[0034] Example 1: See Figure 1, a certain urban sewage treatment plant with a treatment volume of 20,000 m 3 / d. The effluent quality does not meet the new discharge standards. It is required to use A / O type biological aeration filter for capacity expansion, the specific method is:

[0035] A. First measure the effluent quality of the secondary settling tank and the primary settling tank and determine the discharge standards that need to be met:

[0036] a. Determination of the effluent water quality of the secondary sedimentation tank C 1,COD =50mg / L; C 1,BOD5 =20mg / L; C 1,TN =28 mg / L; C 1NH3-N =18 mg / L; C 1,NOX-N =8 mg / L; C 1,SS = 30 mg / L; Tp = 2 mg / L.

[0037] b. Determination of the effluent water quality of the primary sedimentation tank: C 2,COD =220mg / L; C 2,BOD5 =110 mg / L; C 2,TN = 35 mg / L; C 2,NH3-N =30mg / L; C 2,NOX-N =1 mg / L; C 2,SS =80mg / L; Tp≤2mg / L.

[0038] c. The discharge standard that needs to be met is the first-class B standard in the "Pollutio...

Embodiment 2

[0048] Example 2: A city sewage treatment plant with a treatment volume of 30,000 m3 3 / d, all water quality indicators of the effluent have met the requirements of the sewage discharge standard. Now the plant is undergoing expansion construction to further improve the quality of effluent water. The effluent water will be used as landscape environment water in nearby scenic spots. The plan for expansion construction is selected as A / O type biological aeration three-stage treatment, so that the effluent water quality can fully meet the "Sewage Reclamation Use the water quality standards for ornamental environmental water (lakes) in the Engineering Design Code (GB50335-2002).

[0049] A. First measure the effluent quality of the secondary settling tank and the primary settling tank and determine the discharge standards that need to be met:

[0050] 1. Water quality of secondary sedimentation tank effluent:

[0051] C 1,COD =40mg / L C 1 ,=12mg / L

[0052] C 1,TN =20mg / L C 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com