Brewing method based on Northern-school Jiang-flavour Chinese spirits during fermentation processes

A fermentation process and sauce-flavored wine technology, applied in the field of winemaking, can solve problems such as labor consumption, and achieve the effect of reducing the total dosage and increasing different flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

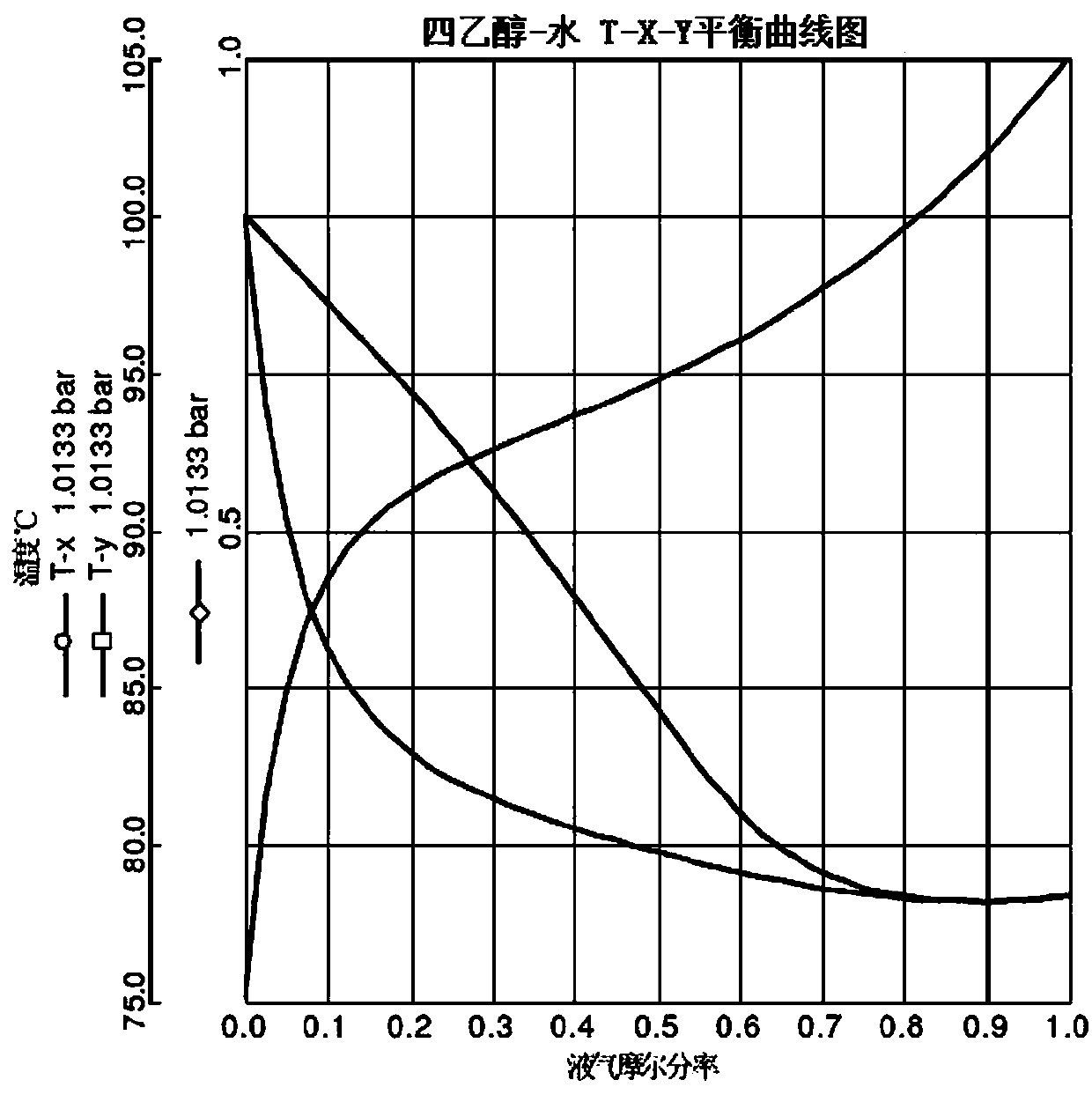

Image

Examples

specific Embodiment approach 1

[0024] The scheme of the present application will be further described below in conjunction with specific examples. The technical solution adopted in the scheme of this application is: a brewing method based on Beipai Maotai-flavored wine in the fermentation process includes the following steps: preparation of fermentation raw materials, first fermentation, second fermentation, first extraction of wine, preparation of rounds of fermentation materials, Rounds of fermentation, rounds of wine extraction and storage; when the wine is taken for the first time, the wine grains are taken out to steam the wine, and the rounds of fermentation materials are prepared simultaneously, and the rounds of fermentation process are carried out; in this scheme, there are 6 rounds of wine extractions in total. Sprinkle the distilled tail wine into the fermented grains after each extraction of wine to continue fermentation; when carrying out the process of extracting and storing wine in rounds, eve...

specific Embodiment approach 2

[0032] After completing steps A-E, in step F, after each round of wine extraction, you can choose to mix Daqu and round fermentation material and then add it to the ceramic fermenter. The weight ratio of Daqu and round fermentation material is 1.5 : 1, wherein the amount of Daqu added is 10% of the previous amount added. Compared with the traditional brewing process of Maotai-flavored liquor, on the one hand, the amount of Daqu used in the process of taking wine in rounds is greatly reduced, which is beneficial to Production cost control; on the other hand, the raw materials after deep fermentation of the round fermentation materials are mixed with Daqu and then added into the continuous fermentation process after the rounds of liquor extraction, without changing the unique quality of the original sauce-flavored liquor It will help to improve the flavor of the final sauce-flavored liquor and give people different taste enjoyment, and it has been found through many tests and tes...

specific Embodiment approach 3

[0034] After completing steps A-E, in step F, after each round of drinking, you can choose to mix Daqu and round fermentation material and then add it to the ceramic fermentation tank. The weight ratio of Daqu and round fermentation material is 2 : 1, wherein the amount of Daqu added is 15% of the previous added amount, and the relative content of the second Daqu is further improved compared with the specific implementation, which is conducive to the further deep fermentation of the wine grains in the fermentation process, and obtains a more intense sauce flavor Liquor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com