Curved screen magnetron sputtering assembly

A technology of magnetron sputtering and curved screen, applied in sputtering plating, ion implantation plating, metal material coating process, etc. Uniformity and other issues, to achieve the effect of stable and accurate operation, low cost, and uniform sputtering deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A curved screen magnetron sputtering assembly provided by the present invention will be further described in detail and completely below in conjunction with the embodiments. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

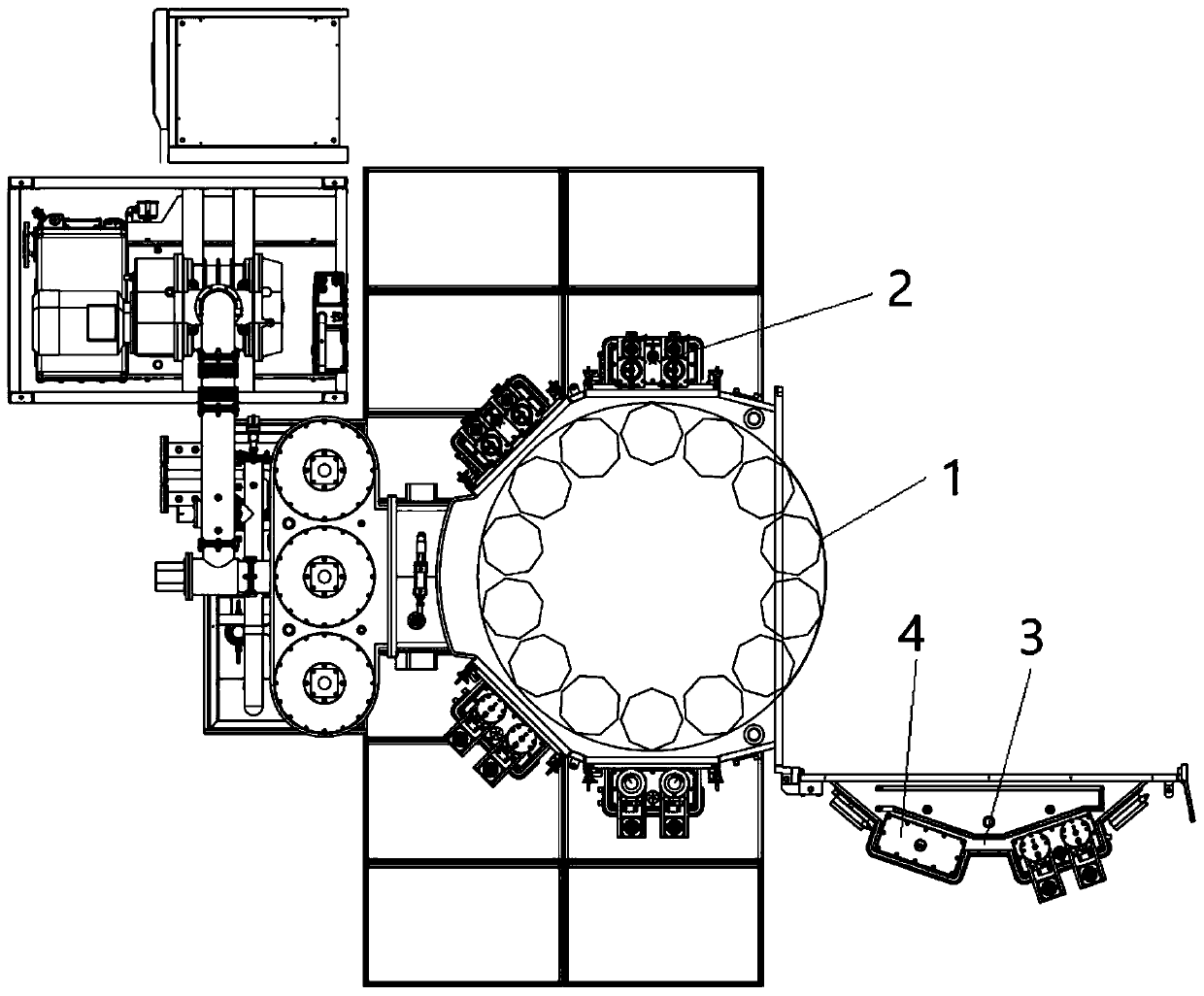

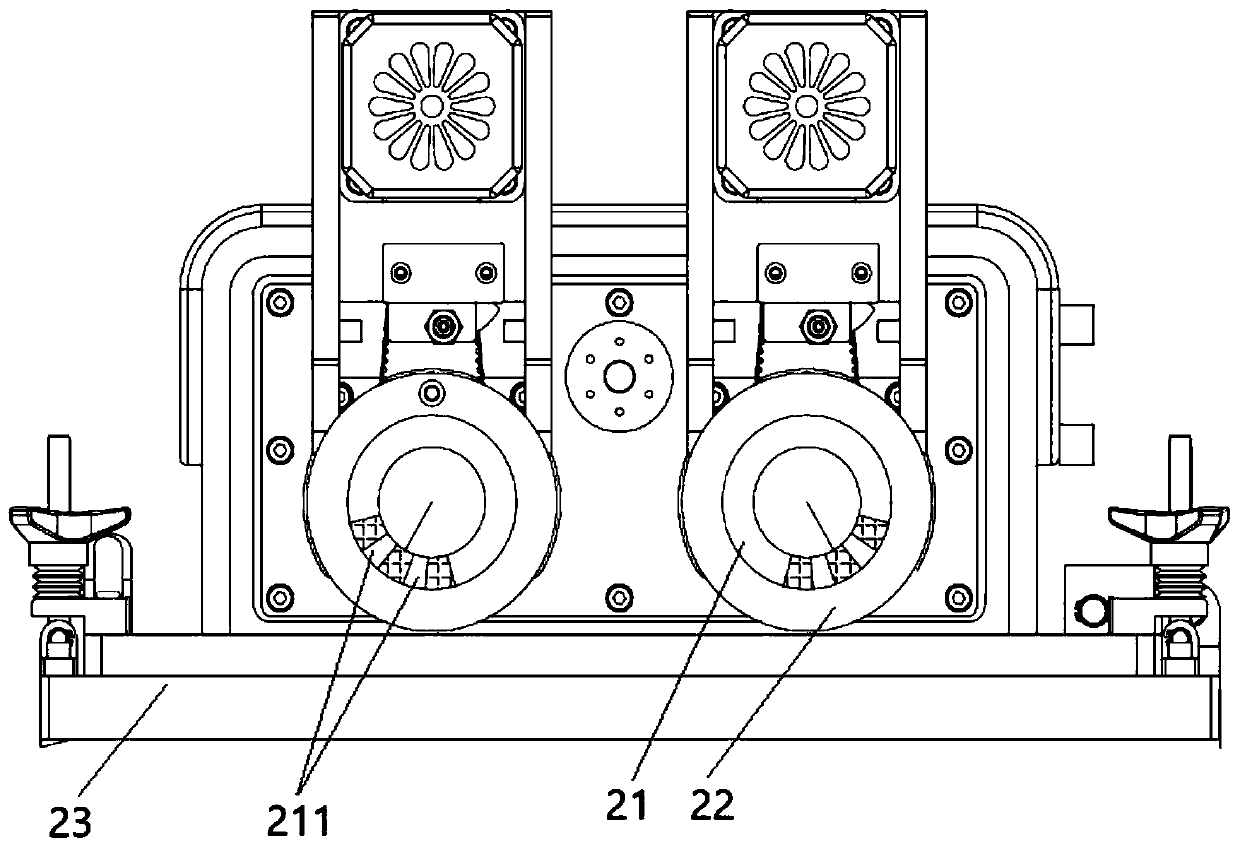

[0031] A curved screen magnetron sputtering component, such as Figure 2 to Figure 9 As shown, it includes a male rotation umbrella turret 1 and multiple sets of cathode assemblies 2, and the rotation umbrella turret 1 and multiple sets of cathode assemblies 2 are installed in the coating chamber in the corresponding coating box, and the coating box is provided with a The door body 3 of the coating chamber is opened or closed, and a molecular pump is provided on the wall of the coating box for vacuuming the coating chamber to facilitate the subsequent vacuum coating operation. The above-mentioned vacuuming operation can adopt the existing vacuuming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com