River channel dredging grab bucket device

A grab and dredging technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as damage to water source navigation and flood discharge capabilities, complex and cumbersome sludge treatment procedures, and increased transportation costs, so as to reduce transportation and post-processing costs. Disposal cost, low cost, easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

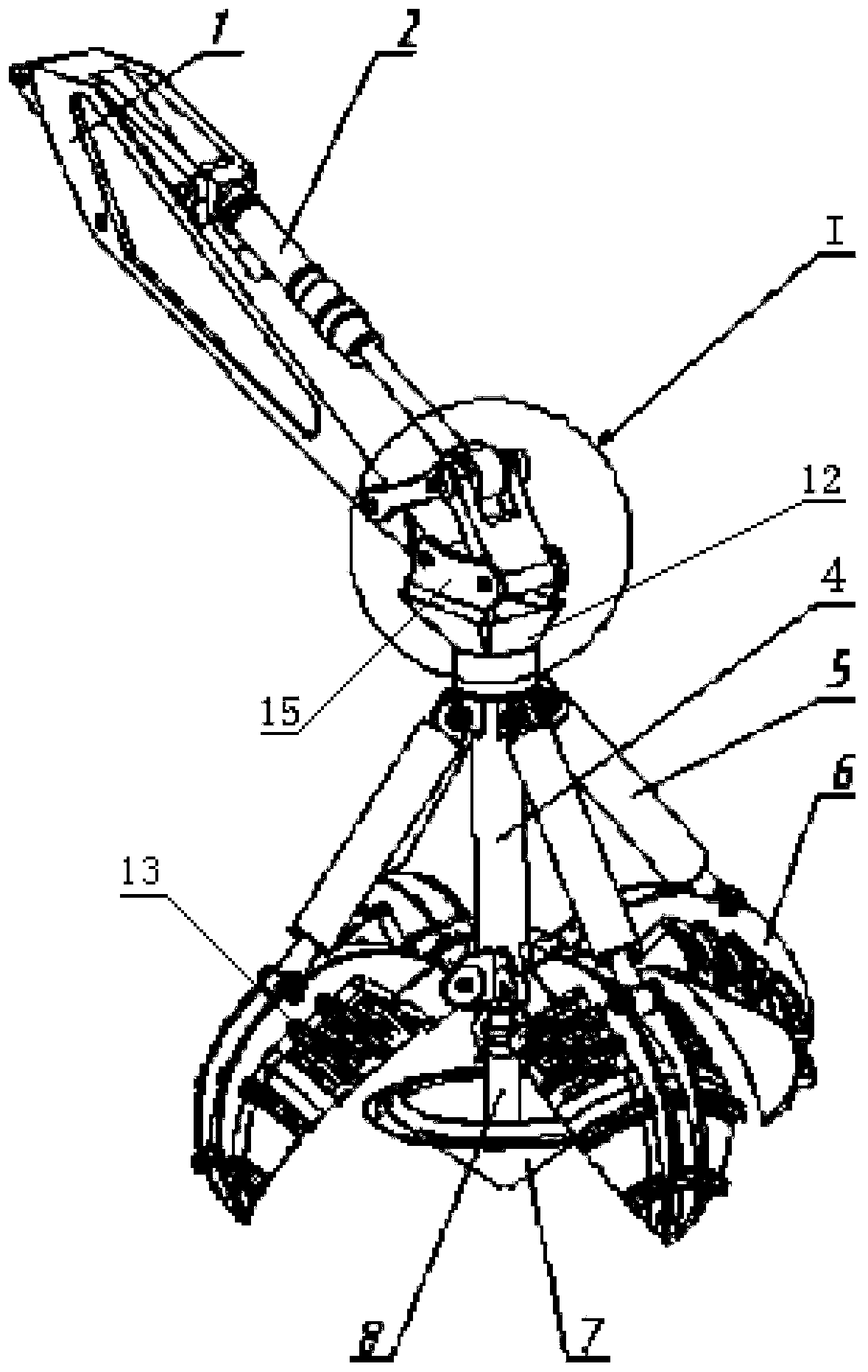

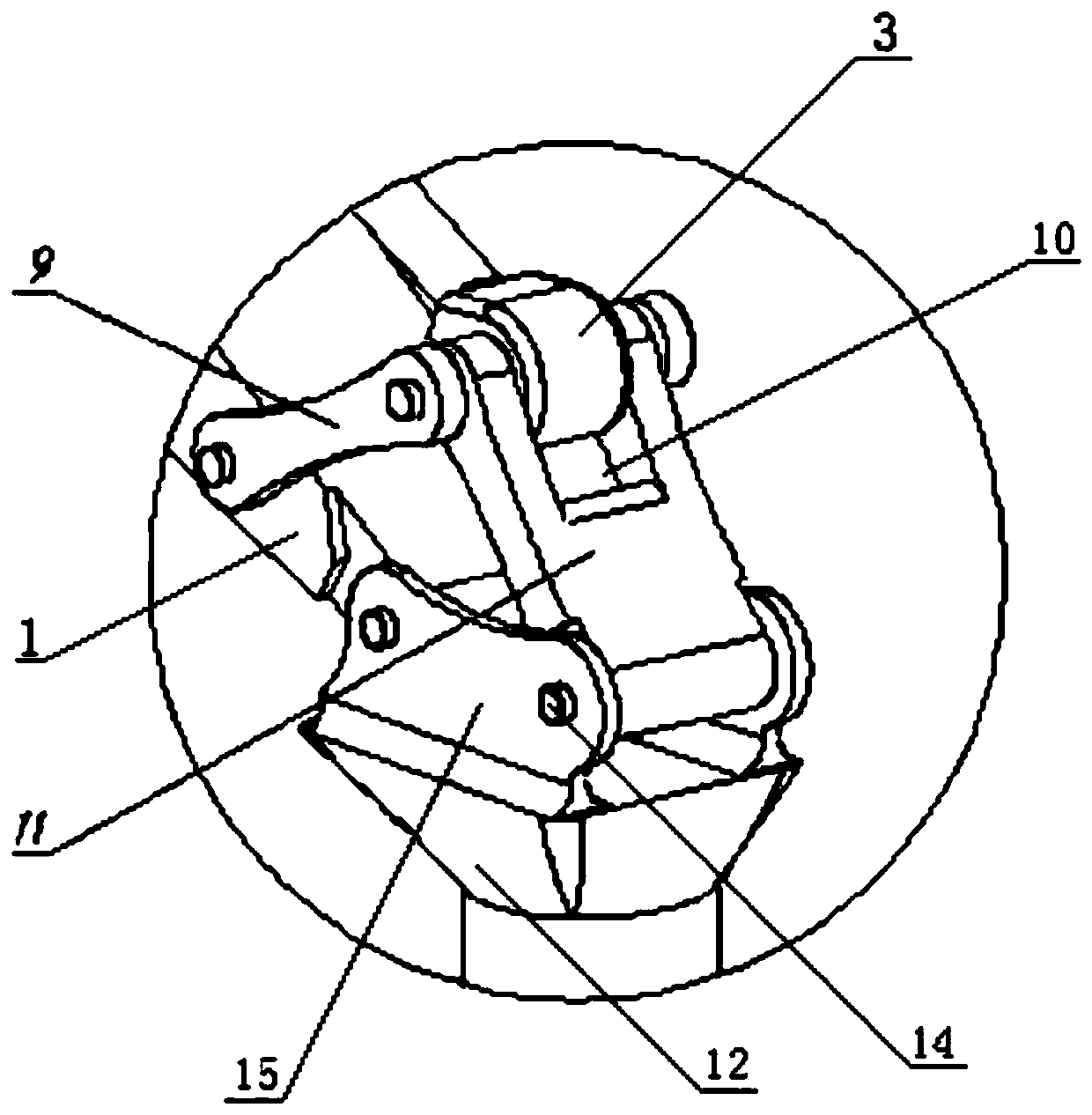

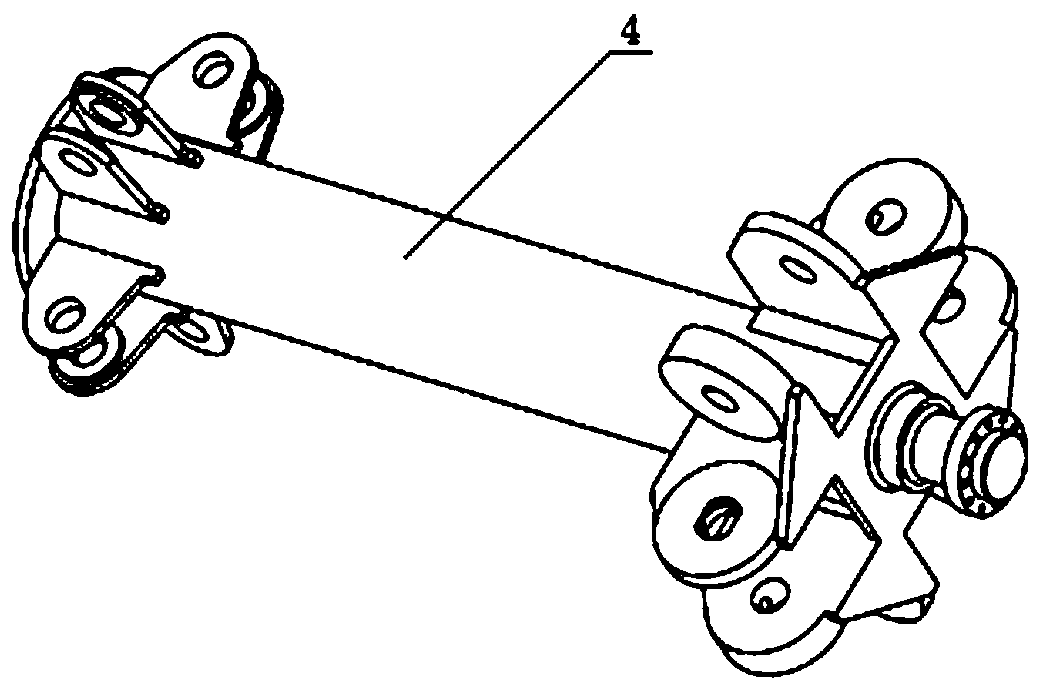

[0025] see Figure 1 to Figure 6 , a river dredging grab device provided in an embodiment of the present invention includes an adjustment mechanism for adjusting the grabbing direction of the grab, a support rod 4, a bucket flap mechanism and a pressure plate mechanism; the adjustment mechanism includes a grab hydraulic cylinder 2, The rocker 9, the connecting rod 11, the connecting seat 12, and the arm 1 of the hydraulic excavator as the frame, and the components of the adjustment mechanism form a plane six-bar mechanism through hinged connection. The driving part of the plane six-bar mechanism is the grab hydraulic cylinder 2 , the plane six-bar mechanism converts the telescopic movement of the grab hydraulic cylinder 2 into the rotary motion of the connecting seat, and increases the rotary angle range of the connecting seat to a large extent; the upper end of the support rod 4 is fixed on the connecting seat 12 of the adjustment mechanism On the top, the support rod 4 moves...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the top of the connecting seat 12 is fixed with an ear plate 15, one side of the ear plate 15 is hinged with the end of the stick 1 through a pin 14, and the other side of the ear plate 17 is hinged through a pin. The shaft 14 is hinged to the end of the connecting rod 11 ; in this embodiment, an ear plate 15 is fixed on the top of the connecting seat 12 to increase the range of rotation angles of the connecting rod 11 around the connecting seat 12 .

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is that the outer surface of the bucket petals 6 is welded with arc-shaped reinforcing ribs. When the pressure plate hydraulic cylinder 8 pushes the pressure plate 7 to squeeze the mud, the bucket petals 6 will be subjected to pressure from the inside to the outside. Due to the expansion force, the bucket petals 6 are easily deformed or even damaged, so it is necessary to strengthen the strength and rigidity of the bucket petals 6. Generally, a stiffened plate is a better choice. Since the outer surface of the bucket petals 6 is curved, so the The added ribs are preferably arc-shaped, fitting the surface of the bucket petals 6, and the specific connection method is welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com