A dredging device for water treatment and its working method

A technology of dredging device and dredging ship, which is applied in the field of water treatment, and can solve the problems of high labor intensity, different degrees of dredging, and low efficiency of dredging work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

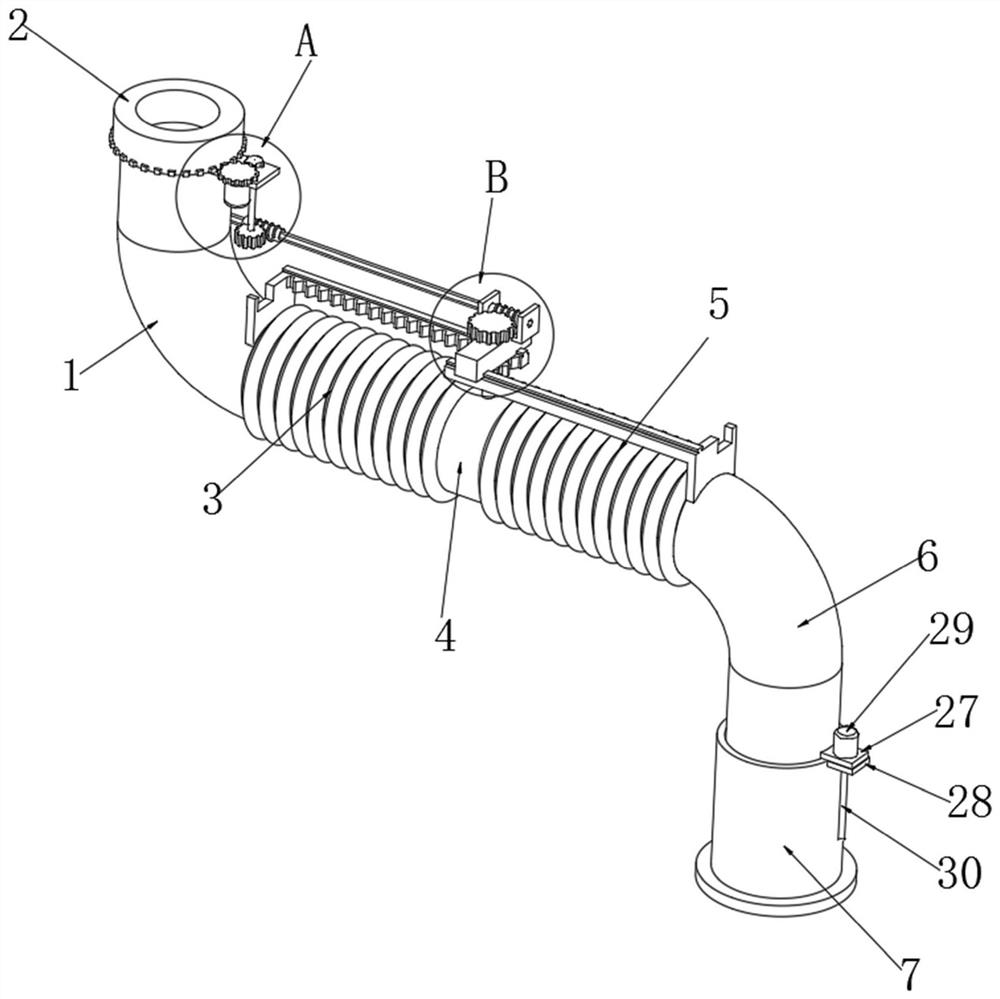

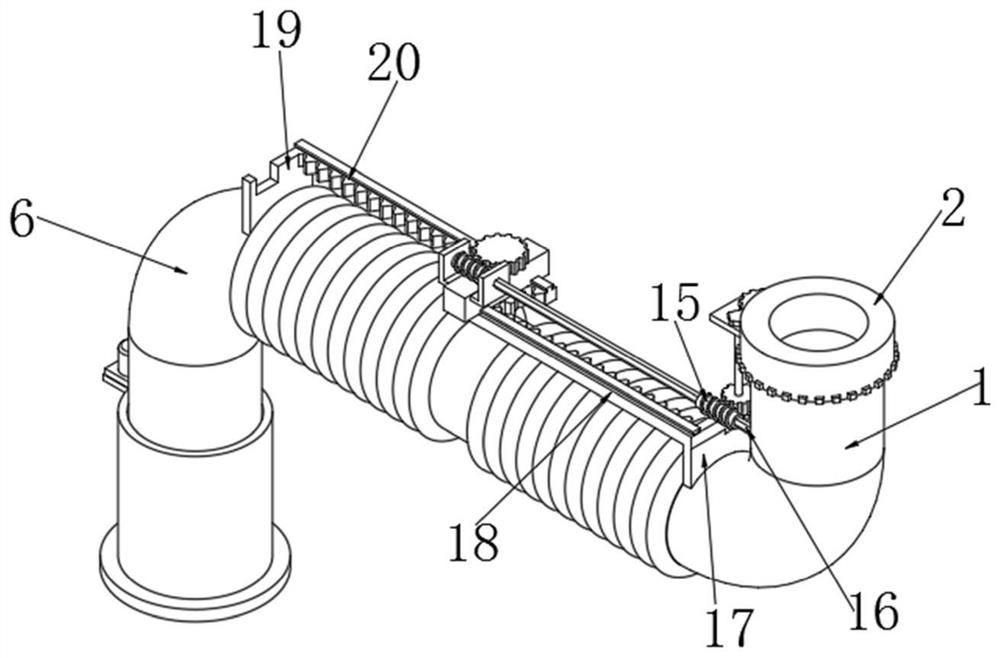

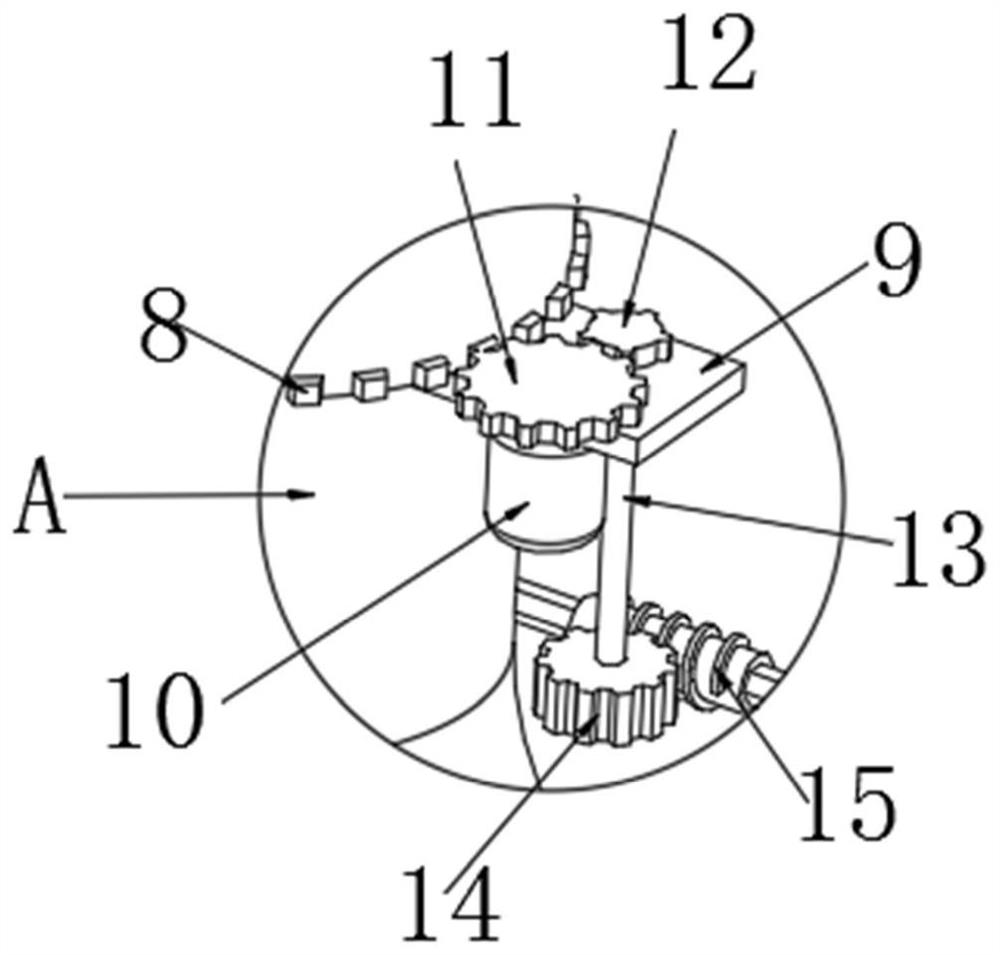

[0035] As an embodiment of the present invention, the rotating sleeve 2 is connected to the first right-angle elbow 1 through a sealed bearing, the outer side of the rotating sleeve 2 is provided with external teeth 8, and the outer side of the first right-angle elbow 1 is installed with a mounting plate 9, and the installation The bottom side of the plate 9 is equipped with a first servo motor 10, the output end of the first servo motor 10 runs through the mounting plate 9 and is equipped with an active tooth 11, and the active tooth 11 meshes with the external teeth 8, and the first servo motor 10 on the mounting plate 9 works The driving gear 11 is driven to rotate, and the rotating driving gear 11 cooperates with the outer teeth 8 of the rotating sleeve 2 to drive the first right-angle elbow 1 to rotate around the rotating sleeve 2 .

[0036]As an embodiment of the present invention, a rotating rod 16 is installed horizontally on the outer side of the first right-angle elbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com