A confluence control valve for double pumps

A control valve and double pump technology, applied in the field of hydraulic valves, can solve the problems of high installation space requirements, complex structure, large volume, etc., and achieve the effects of increasing stability and service life, increasing service life, saving space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

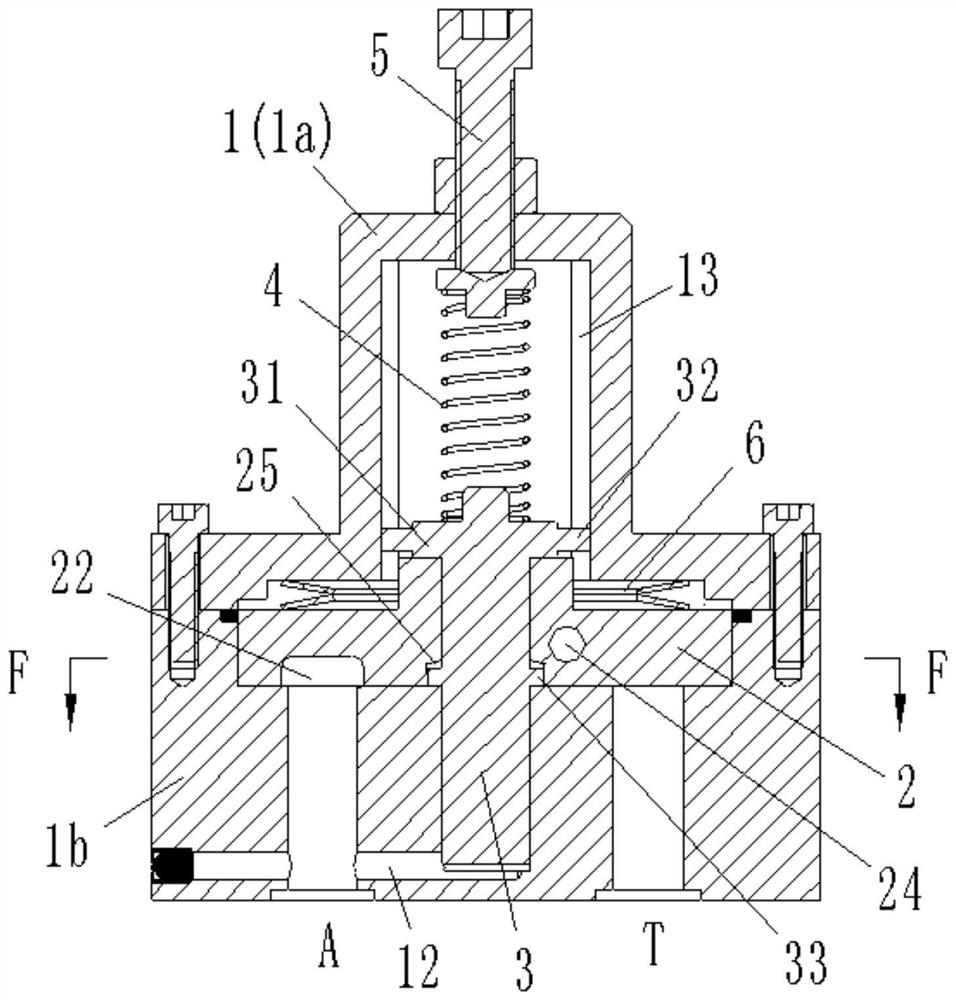

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

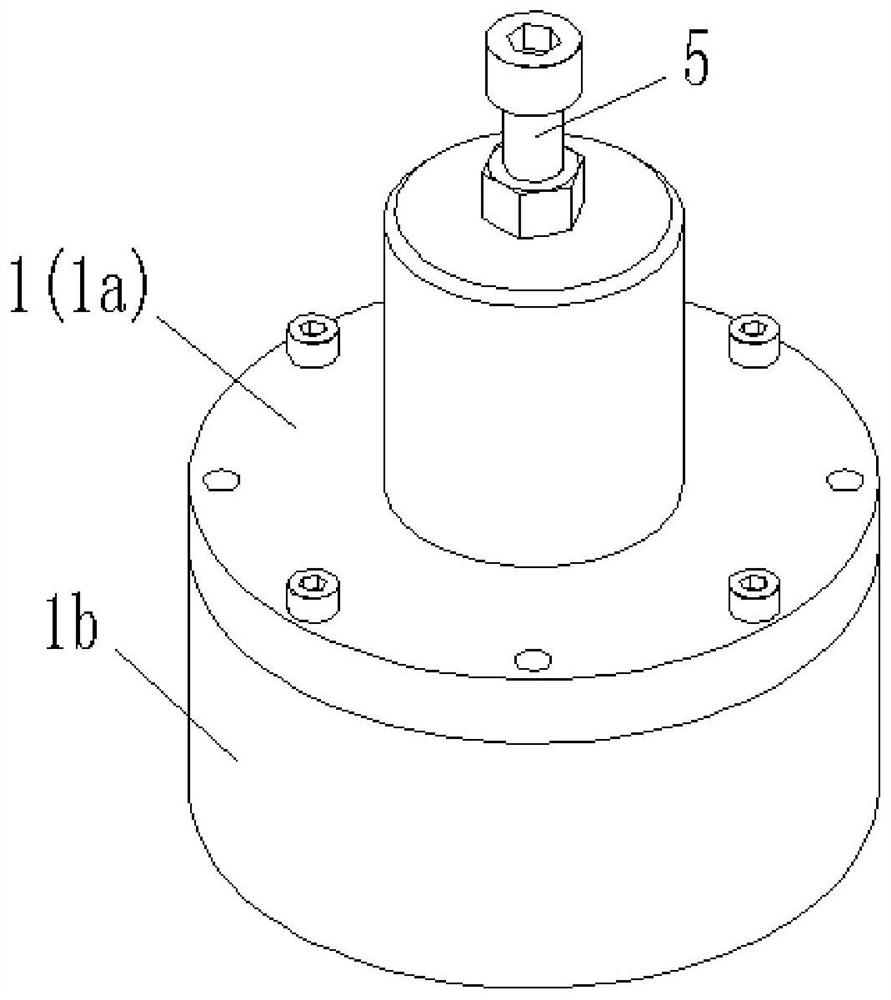

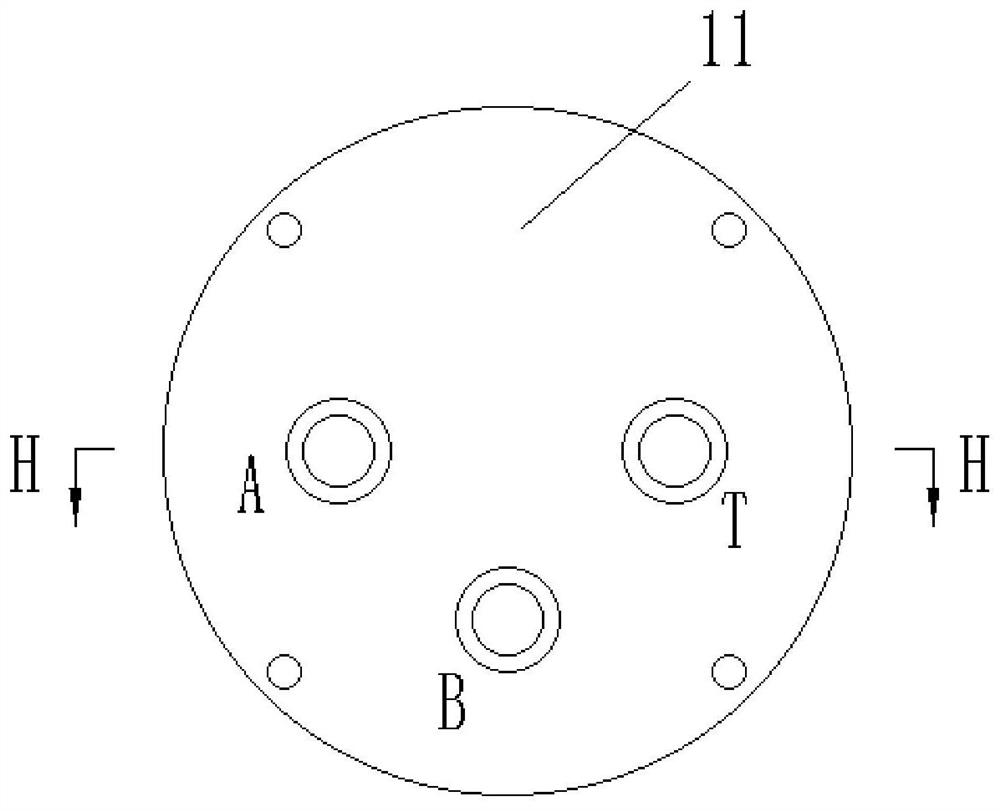

[0032] to combine Figure 1 to Figure 3 As shown, the dual pump confluence control valve in this embodiment includes a valve body 1 , a valve core 2 and a control rod 3 . The mounting surface 11 of the valve body 1 is provided with A port, B port and T port which are not connected to each other, wherein, the A port is used to communicate with the outlet of the small flow pump, the B port is used to communicate with the outlet of the large flow pump, and the T port is used to communicate with the outlet of the large flow pump. The port is connected to the oil return tank. The control rod 3 is located inside the valve body 1 and can move back and forth axially relative to the valve body 1 . The valve core 2 has a disc structure and is sheathed on the control rod 3 inside the valve body 1 . Arc-shaped grooves 22 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com