Construction Machinery Stick Control System

A control system and construction machinery technology, applied in mechanical equipment, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve problems such as slowing down of the operation speed of the stick cylinder, and no longer executing it. Achieve the effect of reducing the number of parts, avoiding rapid acceleration and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be discussed with reference to the accompanying drawings.

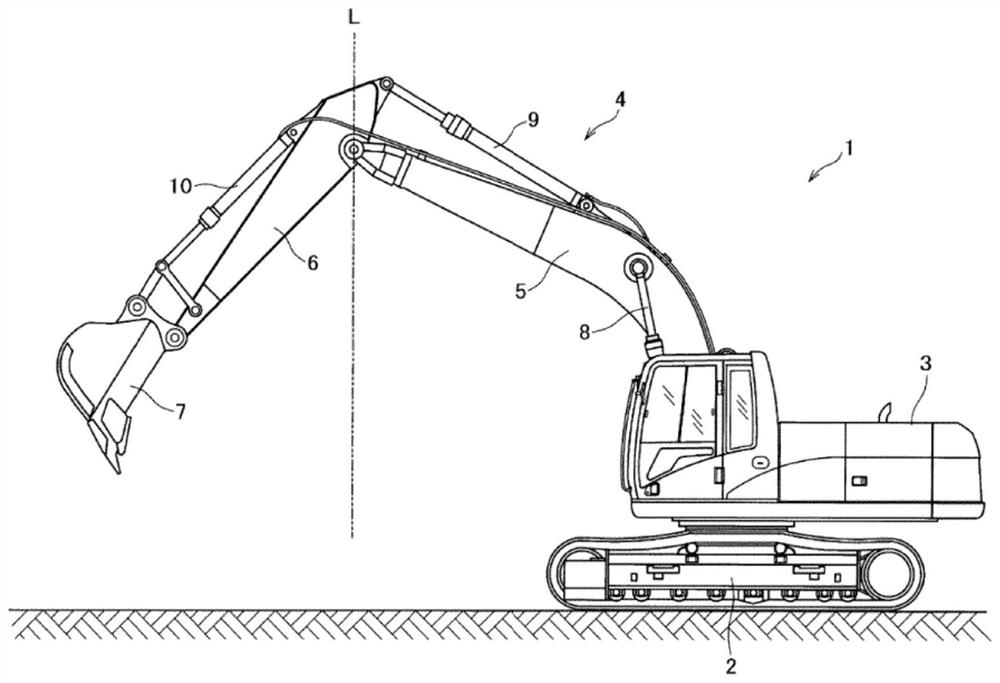

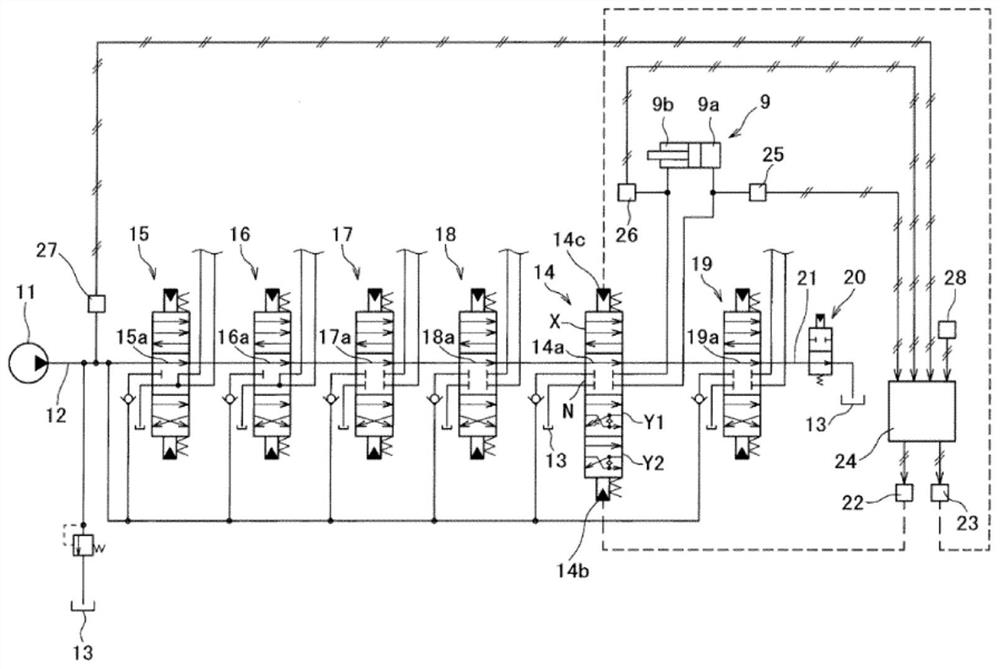

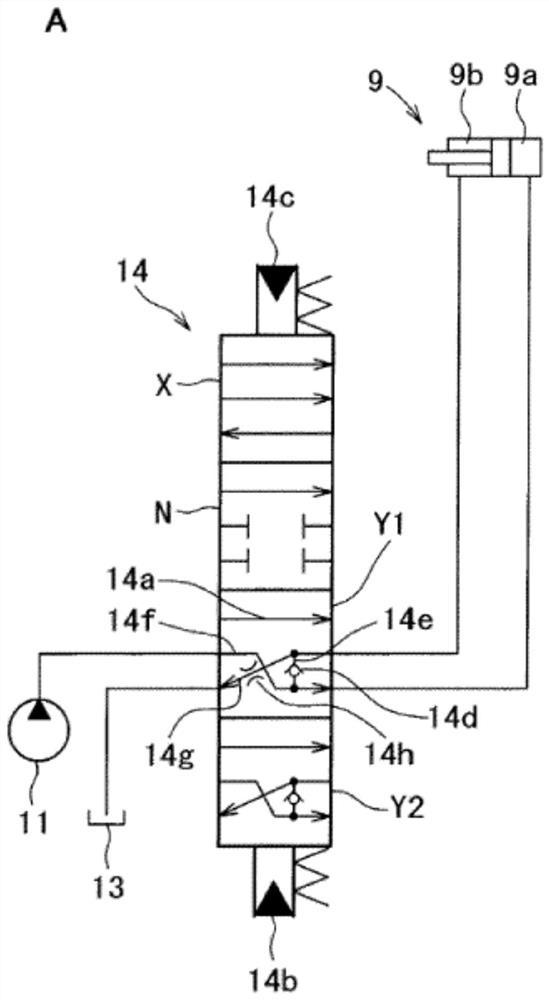

[0026] First, refer to Figure 1 to Figure 4 A first embodiment of the present invention is discussed. figure 1is a view showing a hydraulic excavator 1 as an example of the construction machine of the present invention, the hydraulic excavator 1 includes various parts such as a crawler-type lower traveling body 2; an upper rotating body rotatably supported above the lower traveling member 2 3. The front work implement 4 installed on the upper rotating body 3 . In addition, the front work implement 4 includes a boom 5 having a base end portion vertically swingably supported on the upper rotating body 3; an arm 6 supported to a front end portion of the boom 5 in a longitudinally swingable manner; The bucket 7 is connected to the front end portion of the arm 6 . The hydraulic excavator 1 is provided with various types of hydraulic actuators, such as a boom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com