Air-suction type seeder for small and medium-sized seeds

A small-grain, air-suction technology, applied in the field of agricultural machinery, can solve the problems of unsatisfactory seed adsorption effect, blockage of seeding wheel, increase of manufacturing cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

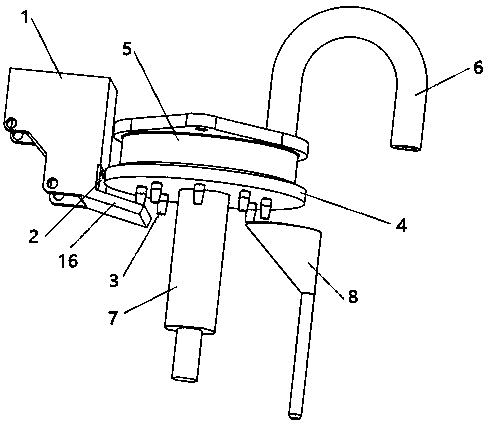

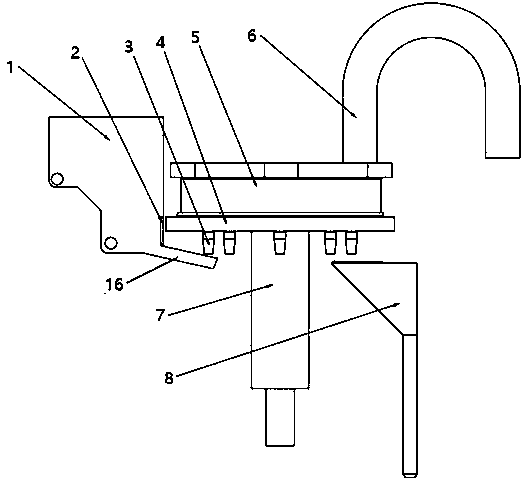

[0032] Such as figure 1 , figure 2 and Figure 5 As shown, the small and medium-sized seed air suction planter includes a seed box 1, a seeding tray 4, a negative pressure air chamber housing 5, and a seeding tube 8. The top two sides of the negative pressure air chamber housing 5 are provided with outwardly extending ears. The plate is fixed on the planter frame by ear plates and bolts. The negative pressure air chamber housing 5 is provided with an annular air chamber 17, and the top of the negative pressure air chamber housing 5 is provided with a negative pressure air passage communicating with the air chamber 17 6. The negative pressure air passage 6 is a U-shaped tube, and the other end is connected with a negative pressure pump, which can generate negative pressure in the air chamber 17. The bottom of the negative pressure air chamber housing 5 and the seeding disc 4 are connected by a snap-in type, and the seeding disc 4 can be The housing 5 rotates relative to the nega...

Embodiment 2

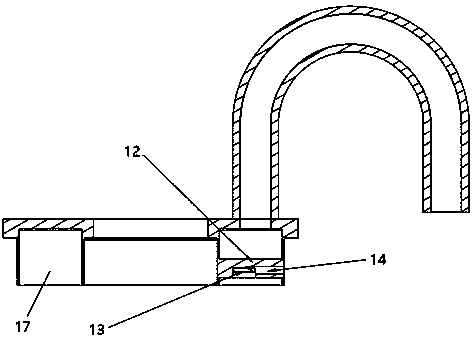

[0035] Such as image 3 with Figure 4 As shown, the airflow barrier 12 is provided with a groove in the middle of the bottom surface, and a photoelectric sensor 13 is installed in the groove. One side of the groove is connected to the outside through a through hole 14 which is used for the wire arrangement and balance release of the photoelectric sensor 13 The pressure groove 18 and the outside atmospheric pressure make it easier for the seed particles to fall from the seed suction nozzle. In this example, the photoelectric sensor 13 is a patch type photoelectric sensor, and the photoelectric sensor 13 is facing the seed suction air passage 10, and is used to detect the luminous flux of the medium hole 11 of the seed suction nozzle 3 to determine whether the hole 11 is filled with seeds, namely According to the information fed back by the photoelectric sensor 13, it is determined whether the broadcast is missed. When the hole 11 has been filled with seeds, the amount of light ...

Embodiment 3

[0037] Such as Image 6 with Figure 7 As shown, the present invention also includes a closed air nozzle 15. The closed air nozzle 15 and the seed suction nozzle 3 are alternately arranged at the bottom of the seed suction air passage 10 in a circular array. Both the closed air nozzle 15 and the seed suction nozzle 3 pass through threads. It is screwed on the bottom of the inhalation airway 10, and the middle part of the closed air nozzle 15 is a blind hole. After being installed on the inhalation airway 10, the sealing effect can be achieved. The closed air nozzle 15 and the inhalation air nozzle 3 are arranged at intervals to increase the relative The arrangement distance between two adjacent seed suction nozzles 3 can realize a variety of different row spacing sowing under the premise that the rotation speed of the seed metering plate 4 is unchanged, and meet the different agronomic requirements of different seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com