Cantilever cattle bed manure collection and bedding spreader

A cantilever type, cattle bed technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of difficult manure cleaning, low efficiency, and affecting the normal operation of manure treatment systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

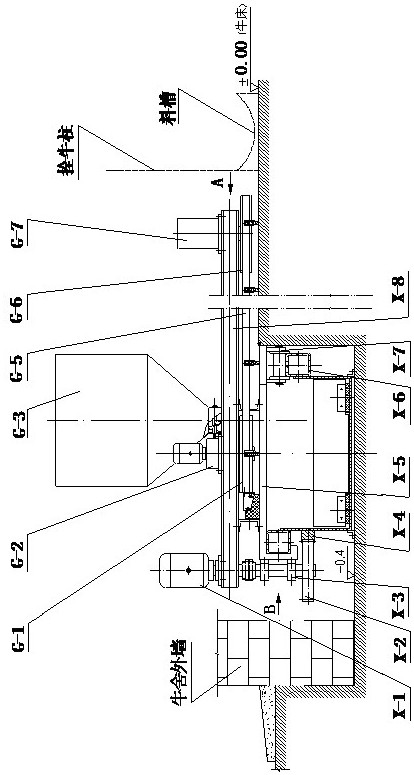

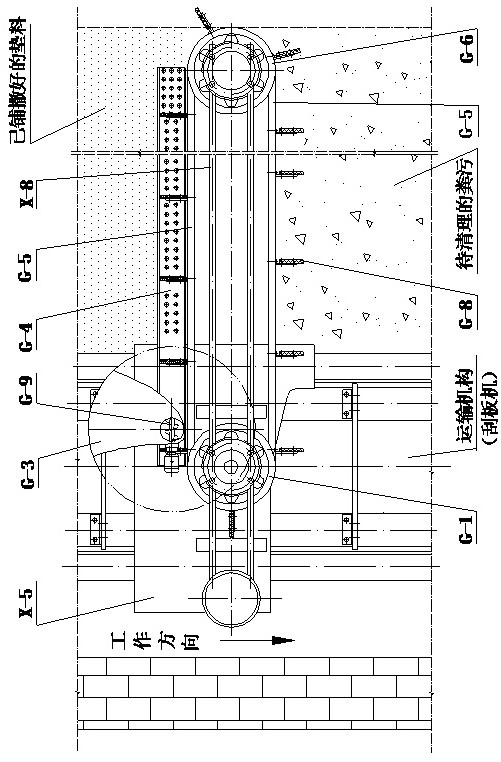

[0013] At the position near the outer wall in the longitudinal direction of the cowshed, reserve a pit about 25 cm below the level of the cattle bed, with a rectangular cross-section and a full length, so as to facilitate the installation of ordinary commodity scrapers.

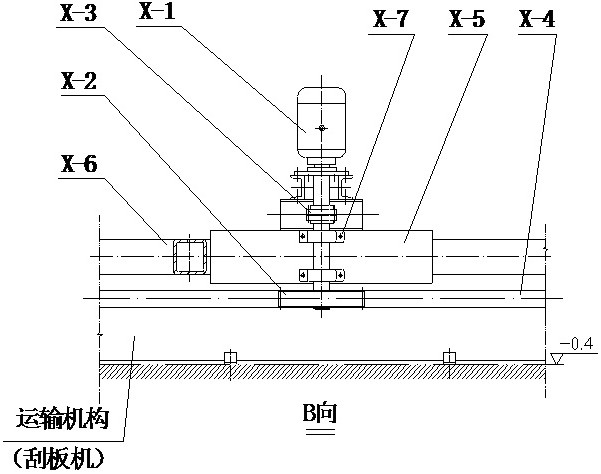

[0014] Two linear guide rails X-6 are installed horizontally on the two side vertical plates of the scraper machine, so that the working mechanism G can move vertically and linearly on it; the traveling mechanism X rides on the scraper machine tank as a whole , on the outer facade of one side of the tank body, a long single rack X-4 is installed; after the gear X-2 is connected to the power of the walking motor X-1, it meshes with the rack X-4 and starts to move. Relative movement, so that the traveling mechanism X as a whole moves in a straight line at a uniform speed along the longitudinal direction of the scraper machine; the main components of the working mechanism G are installed on the cantilever X-8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com