Precipitation apparatus for camellia oleosa seed oil production process

A technology of production process and sedimentation device, which is applied in the direction of sedimentation separation, settling tank, fat production, etc., can solve the problems of polluting camellia oleifera seed oil, difficult to clean oil residue, etc., and achieve the effect of improving the sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

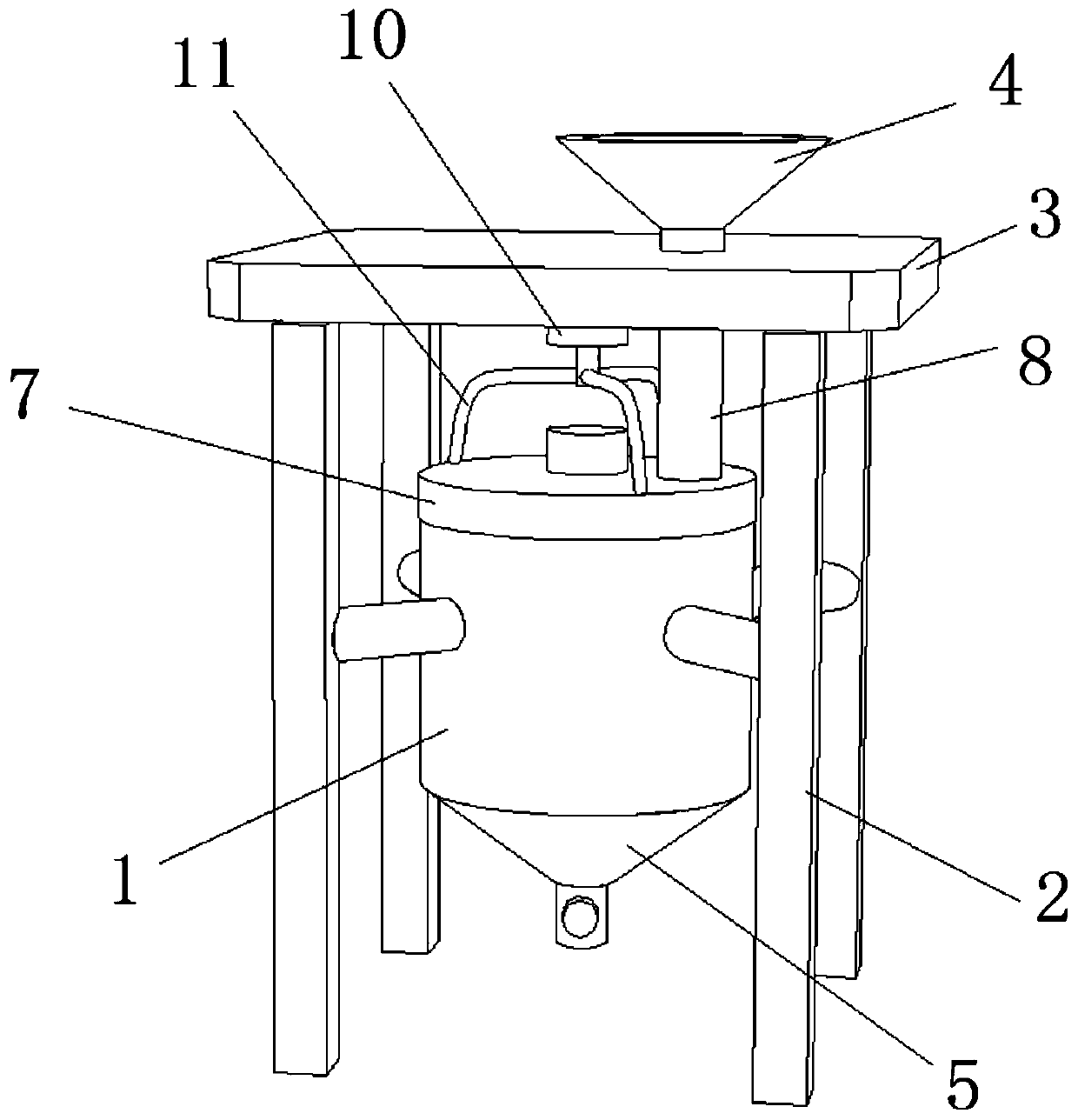

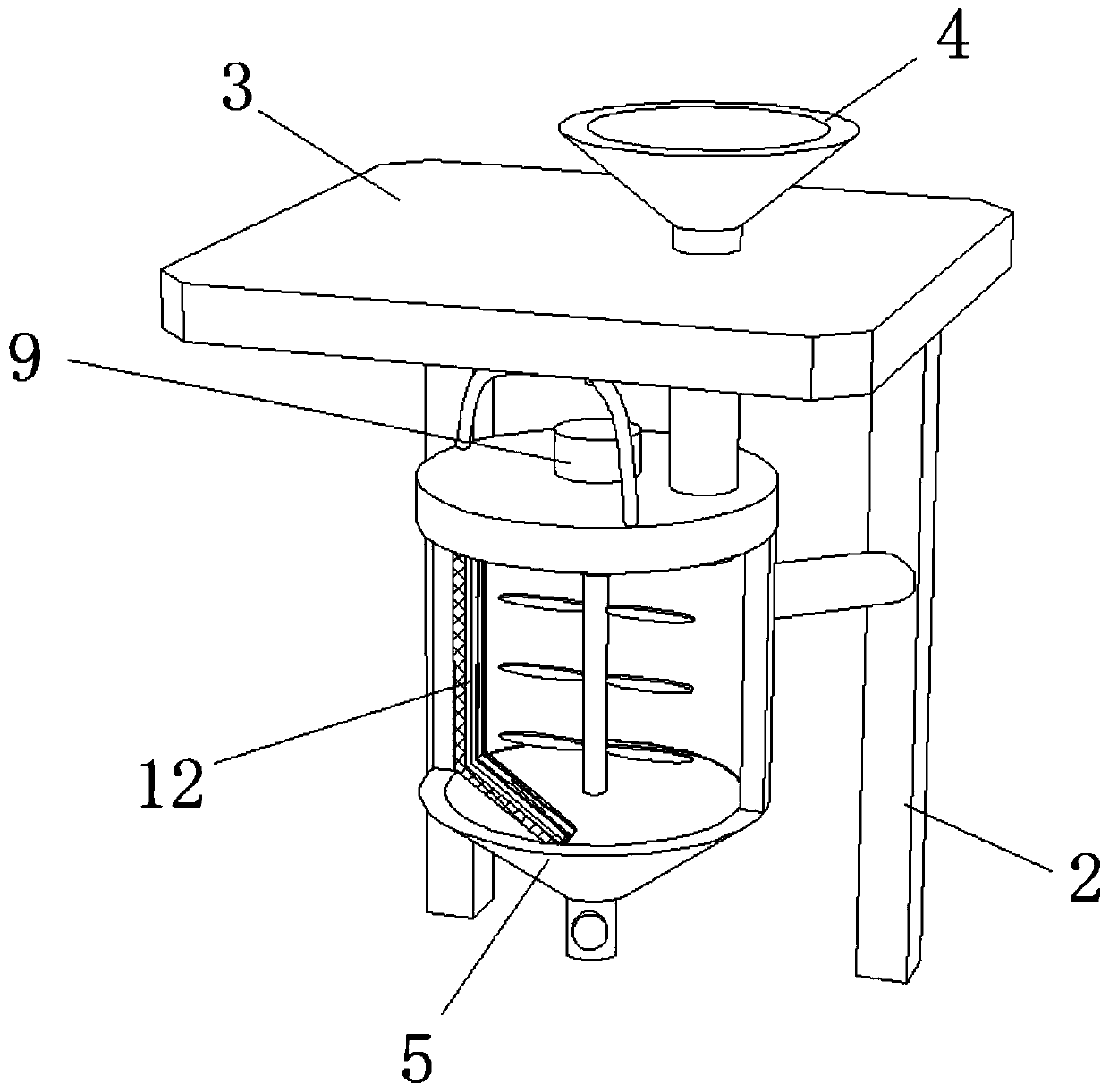

[0027] A kind of sedimentation device in the production process of camellia oleifera seed oil, such as Figure 1-3 As shown, it includes an oil barrel 1 with a top cover 7 connected to the upper end, a feed hopper 4 connected to the top cover 7, a discharge hopper 5 with an opening and closing valve connected to the lower end of the oil barrel 1, and a support on the outer end of the oil barrel 1. The motor 9 is connected to the upper end of the leg 2 and the upper cover 7 , the power output end of the motor 9 is connected to a rotating shaft 17 , and a plurality of stirring blades 18 are connected to the side end of the rotating shaft 17 .

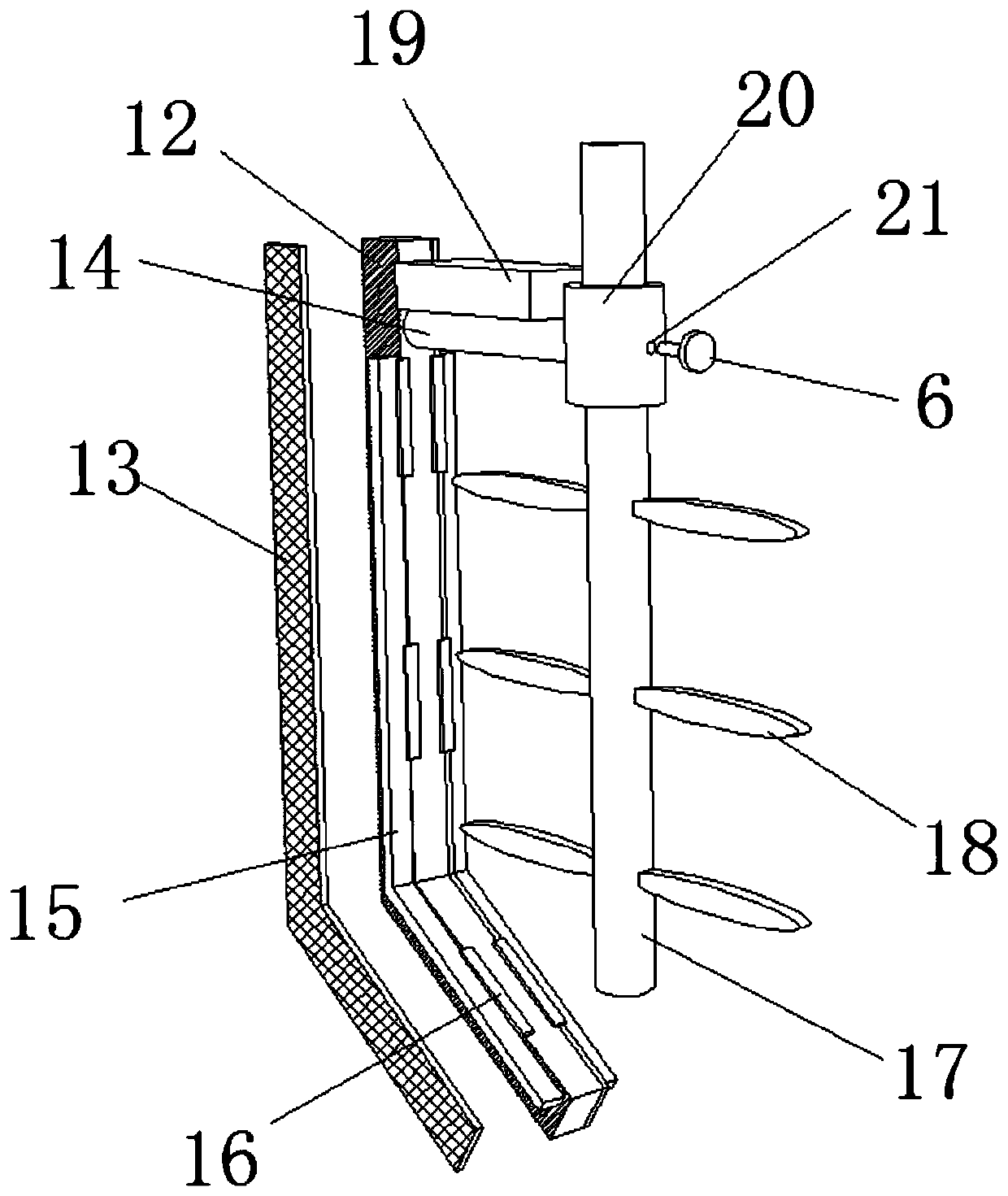

[0028] In order to solve the problem that it is difficult to clean the oil residue adhered to the inner wall of the oil tank during the production of Camellia oleifera seed oil; Figure 1-3 As shown, the upper end side of the rotating shaft 17 is connected with a fixed seat 14, and the end of the fixed seat 14 away from the rotating shaft...

Embodiment 2

[0034] A kind of sedimentation device in the production process of camellia oleifera seed oil, such as image 3 As shown, in order to further solve the problem of cleaning the oil residue adhered to the inner wall of the oil tank during the production process of camellia oleifera seed oil; this embodiment makes the following improvements on the basis of embodiment 1: the scraping mechanism also includes a scraper 15, and the scraper 15 is connected At the end of the slag suction box 12 away from the inner wall of the oil drum 1, the scraper 15 can collect the oil residue scraped off by the scum suction box 12 at the slag suction port at the side end of the scum suction box 12, so as to completely absorb the oil residue.

[0035] Wherein, a plurality of buckles 16 are connected between the scraper 15 and the slag suction box 12 to facilitate disassembly and replacement of the scraper 15 .

[0036] Wherein, a filter screen 13 is provided at the slag suction port at the side end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com