Feeding device for pharmacy

A material port and material tube technology, which is applied in the field of pharmaceutical feeding devices, can solve the problems of pharmaceutical process efficiency limitation, inconvenient raw material pretreatment, etc., and achieve the effects of easy disassembly and cleaning, avoiding pollution, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

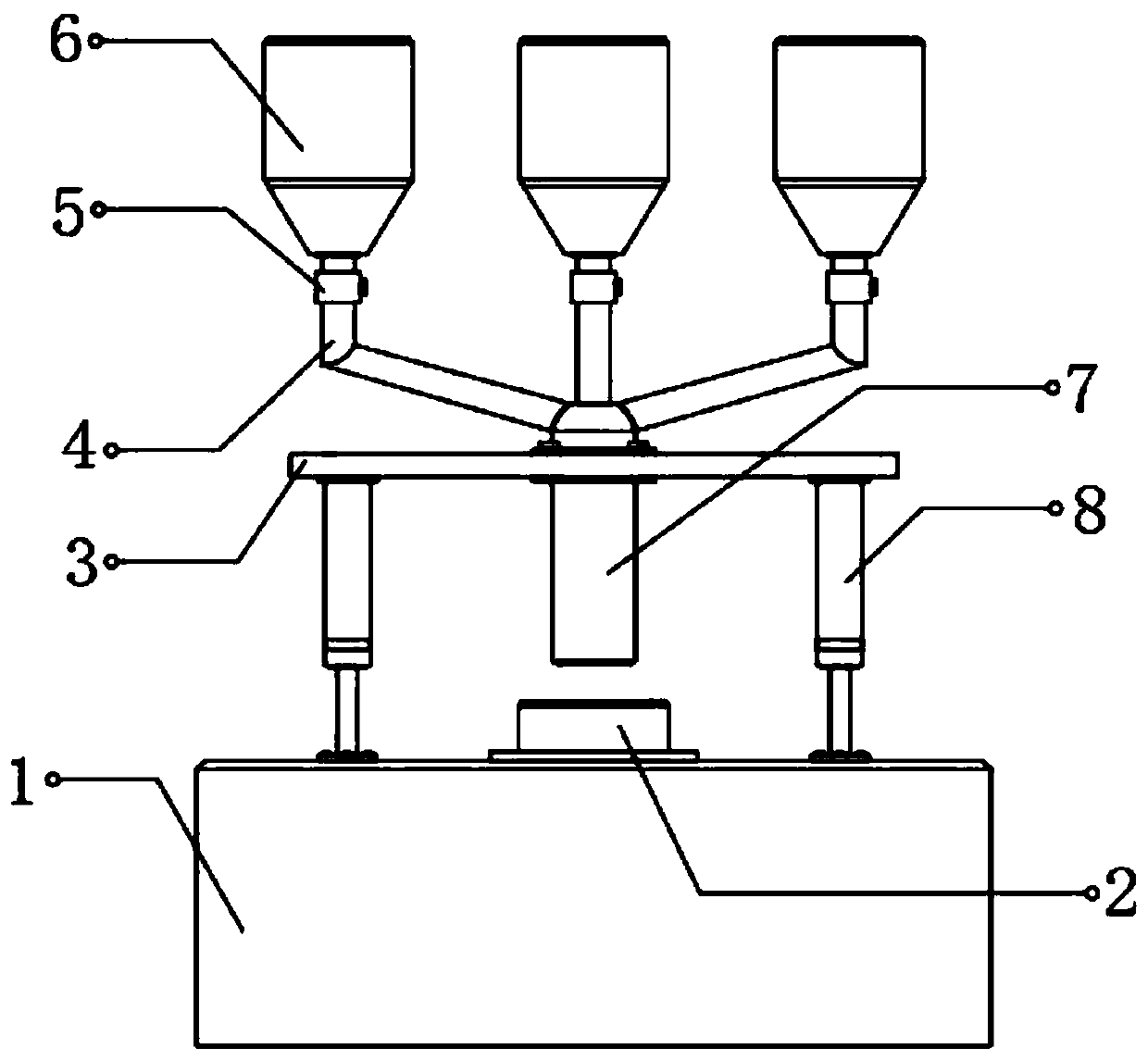

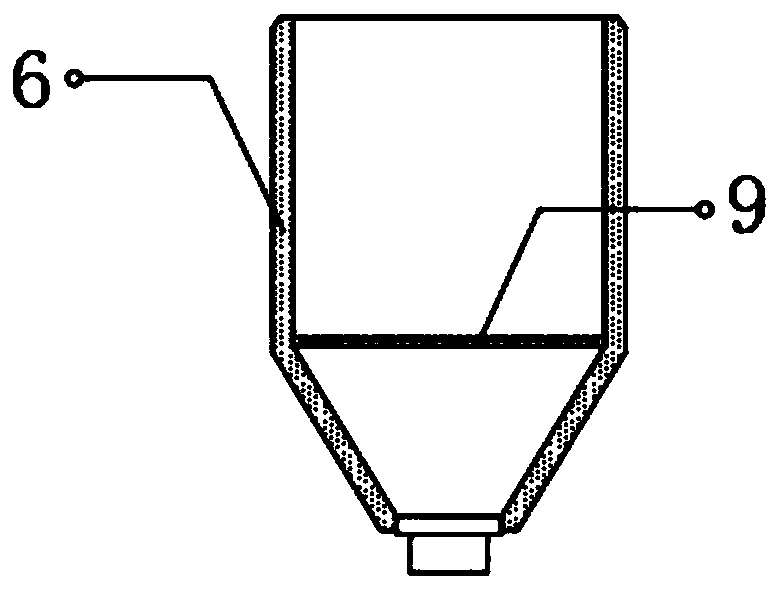

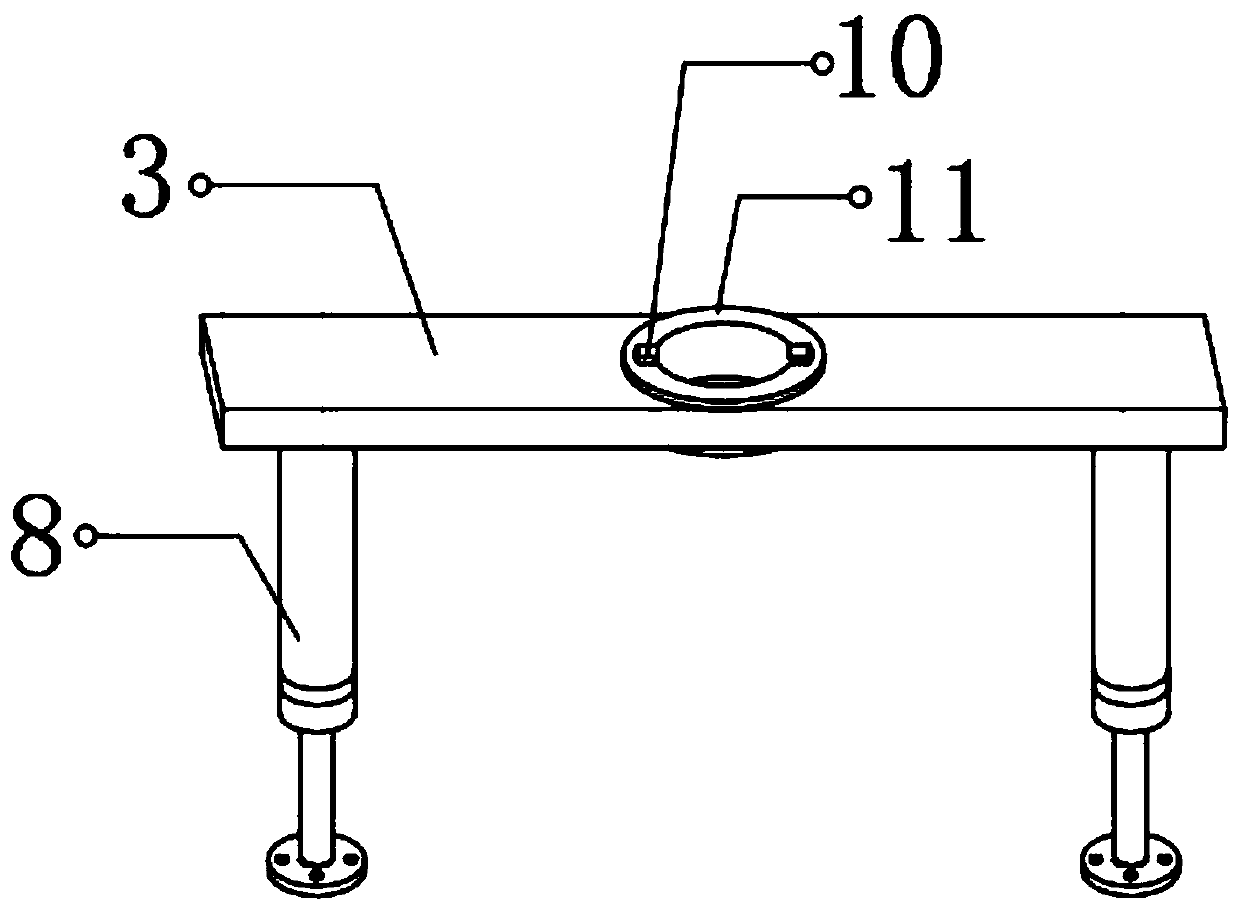

[0027] Reference Figure 1-3 , A pharmaceutical feeding device, comprising a reaction mechanism 1 and a feeding port 2. The feeding port 2 is set in the middle position of the top of the reaction mechanism 1, and the upper part of the reaction mechanism 1 is fixedly connected with a lifting plate 3, and the lifting plate 3 A lowering pipe 7 is provided in the middle. The top of the lowering pipe 7 is fixedly connected with three branch pipes 4, and the tops of the three branch pipes 4 are fixedly connected with an upper hopper 6, and the tops of the three branch pipes 4 are provided with solenoid valves 5, and The inner wall of the bottom of the three upper hoppers 6 is equipped with a filter screen 9. Before feeding, different solutions can be pre-prepared in the upper hopper 6. After the various raw materials are fully dissolved, the corresponding solenoid valve 5 can be opened, and the solution will pass The corresponding branch pipe 4 merges into the feeding pipe 7, and fin...

Embodiment 2

[0034] Reference Figure 4 , A pharmaceutical loading device. Compared with embodiment 1, this embodiment is provided with struts 13 on both sides of the top of the lifting plate 3, and the tops of the two struts 13 are fixedly connected with springs 12, two The top ends of the springs 12 are respectively fixedly connected with the outer walls of the adjacent branch pipes 4, and the bottom ends of the two support rods 13 are both sleeved with rubber sleeves 14.

[0035] Working principle: When the lower material tube 7 is inserted into the collar 11, the two struts 13 compress the spring 12 upwards to buffer the falling process of the upper hopper 6, the branch pipe 4 and the lower material tube 7, and it can also be used after the falling For the supporting effect, the rubber sleeve 14 buffers the wear between the brace 13 and the lifting plate 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com