Reinforcement Cage Welding or Lashing Devices

A steel cage and stirrup technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of easy bending and deformation of longitudinal bars, narrow use range, shaking or swaying, etc., so as to reduce the labor intensity of workers and improve production. Efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

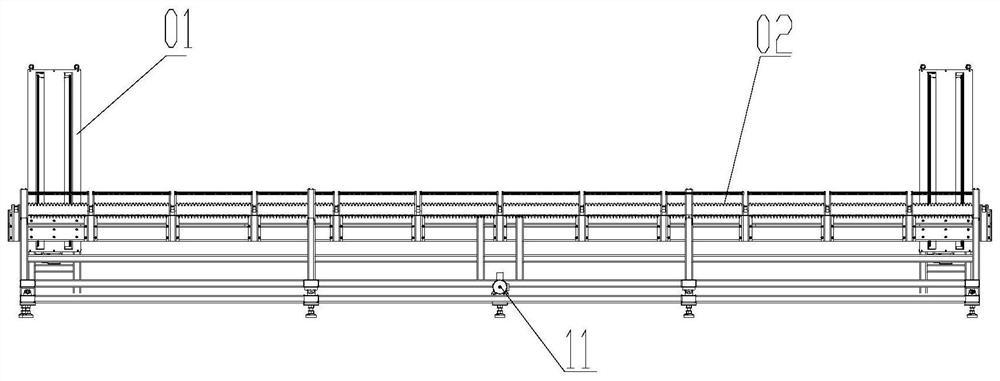

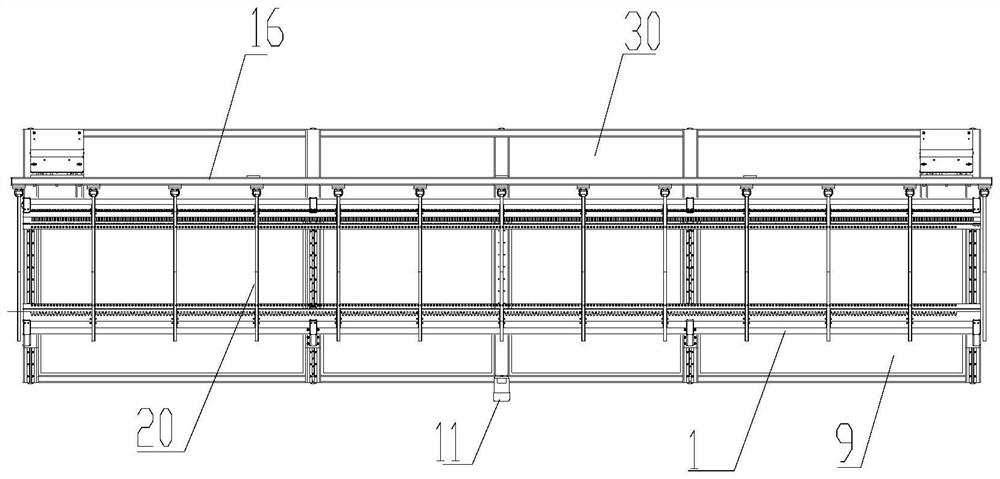

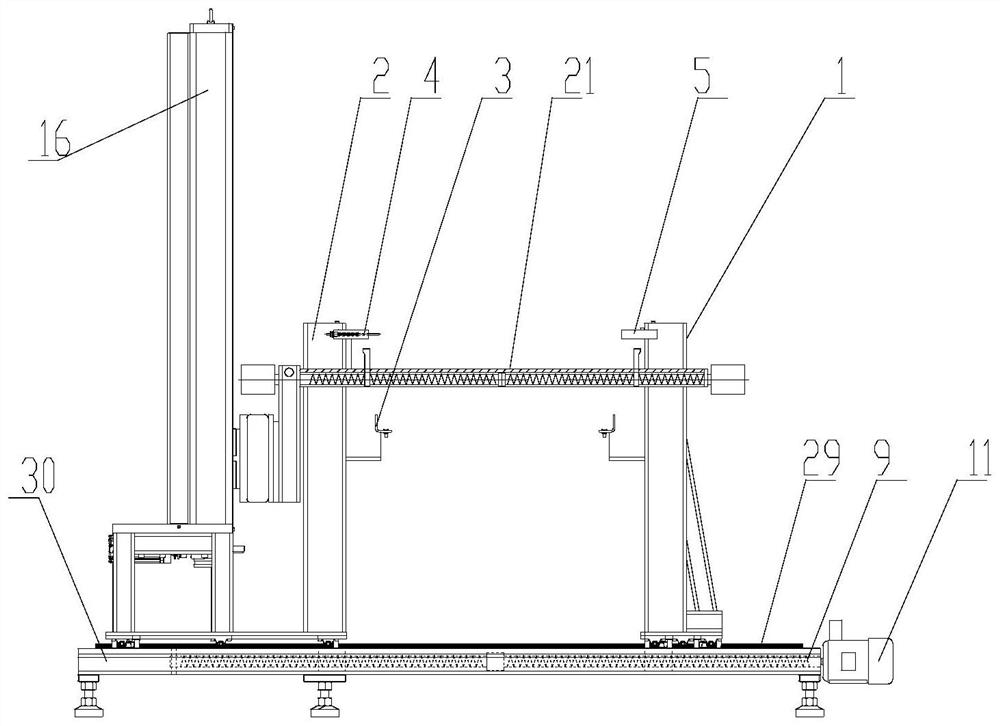

[0048] Reference attached figure 1 to attach Figure 4As shown, the steel cage welding or binding device in this embodiment includes a longitudinal bar positioning machine 01 and a stirrup bar positioning machine 02, and the longitudinal bar positioning machine 01 includes a lifting seat 16 and a plurality of longitudinal bar supports arranged on the lifting seat 16 Assemblies 20, each longitudinal reinforcement support assembly 20 includes support bars 21 horizontally arranged for supporting longitudinal reinforcement 15; Two stirrup retaining mechanisms 1, each set of stirrup retaining mechanisms 1 includes a vertically arranged fixed plate 2 and a retaining plate 3 arranged on the side of the fixed plate 2, and the retaining plate 3 is provided with a plurality of accommodating stirrups 12, the slot of the first stirrup clamping mechanism and the clamping slot of the second stirrup clamping mechanism 1 are opposite to form a stirrup receiving groove. The longitudinal bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com