A high-temperature-resistant suction cup top post for installation of high-temperature radioactive sources

A radioactive source and installation technology, which is applied in the field of high-temperature-resistant suction cup top column for high-temperature radioactive source installation, can solve problems such as no radioactive source, electromagnetic sucker cannot be used, and the sucker cannot meet the installation requirements of radioactive source and radioactive source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Due to the preparation process, the upper end surface of the workpiece (high temperature radiation source) may have pits or protrusions, resulting in a large gap between the end surface of the workpiece and the lower end surface of the suction cup top column. If only the end surface is sealed, it may cause insufficient negative pressure. Therefore, the workpiece cannot be sucked, and during the lateral movement of the suction cup top column, the end surface of the workpiece and the end surface of the top column may be separated due to inertia, causing the radioactive source to fall.

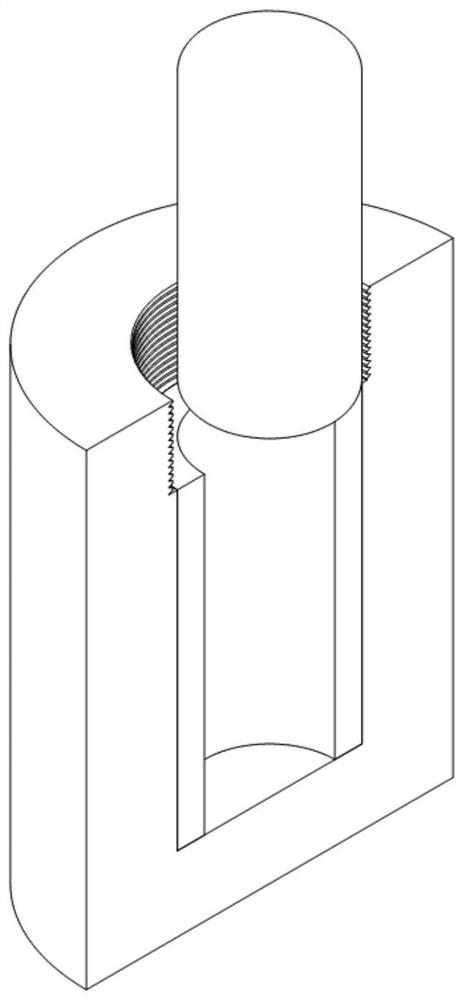

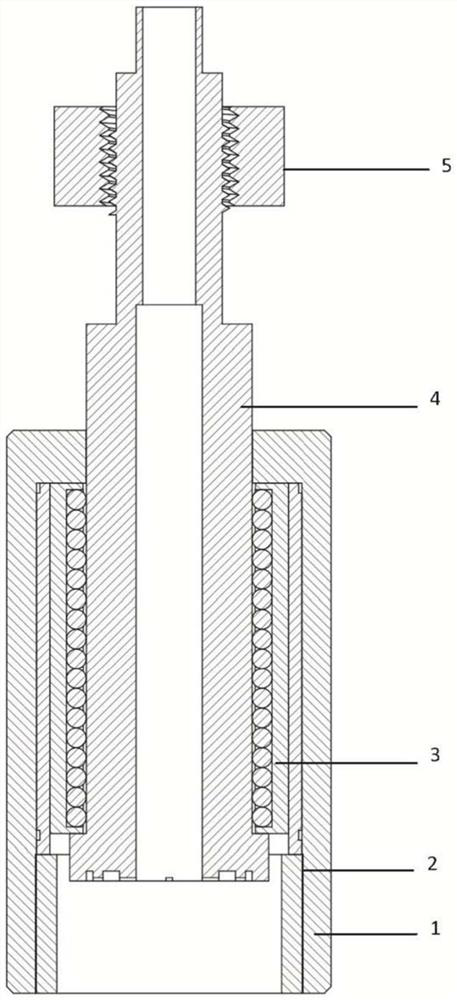

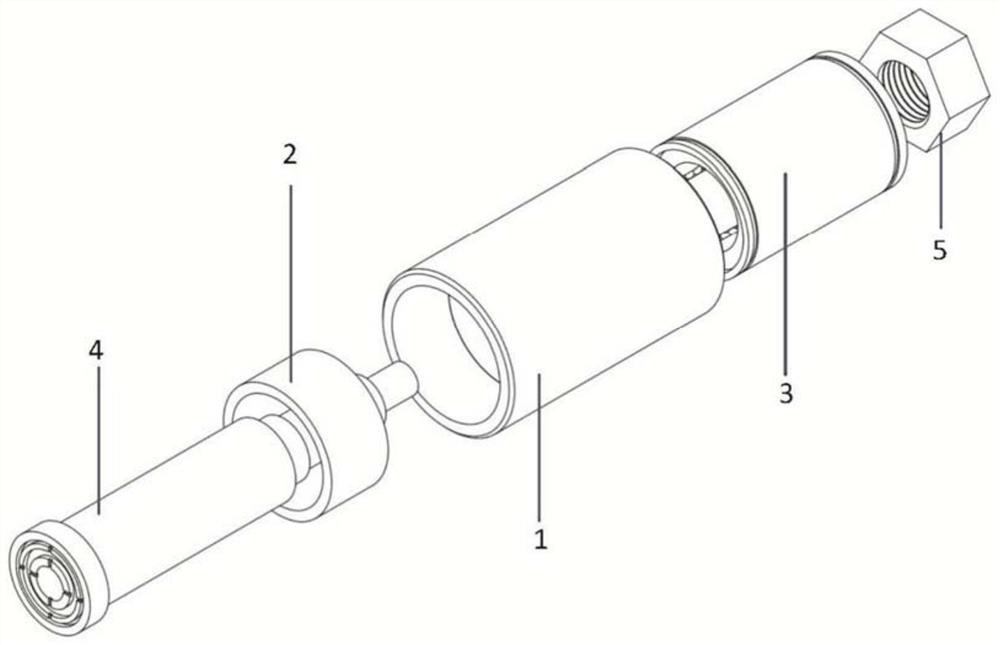

[0027] In view of this, the present invention provides a high-temperature-resistant suction cup top post for installing a high-temperature radioactive source, such as figure 2 and image 3 As shown, it includes a hollow suction cup top column 4 and a protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com