structure of pfa lined pump casing

A technology of lining and pump casing, which is applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of aggravating residual stress, high manufacturing cost, and long production time, and achieve high reliability Operational capability, shortened production time, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0084] Suitable for high temperature of 200°C, PFA is a highly corrosion-resistant plastic, but its molding shrinkage is quite high. When using injection molding technology and containing metal inserts, it is necessary to prevent excessive residual stress, especially for large pump casings and pump inlet diameters When it is above 80mm or the impeller diameter is above 200mm.

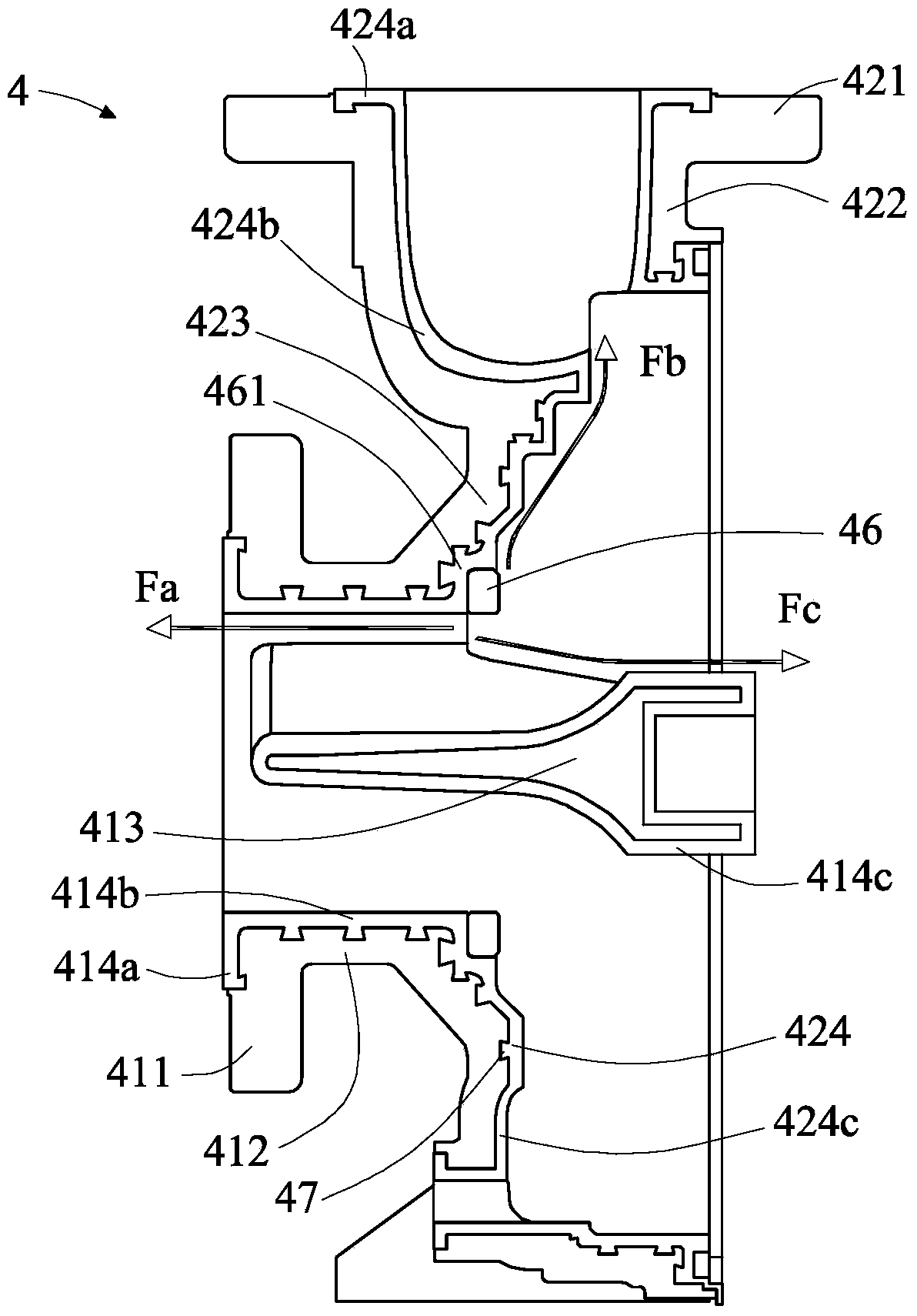

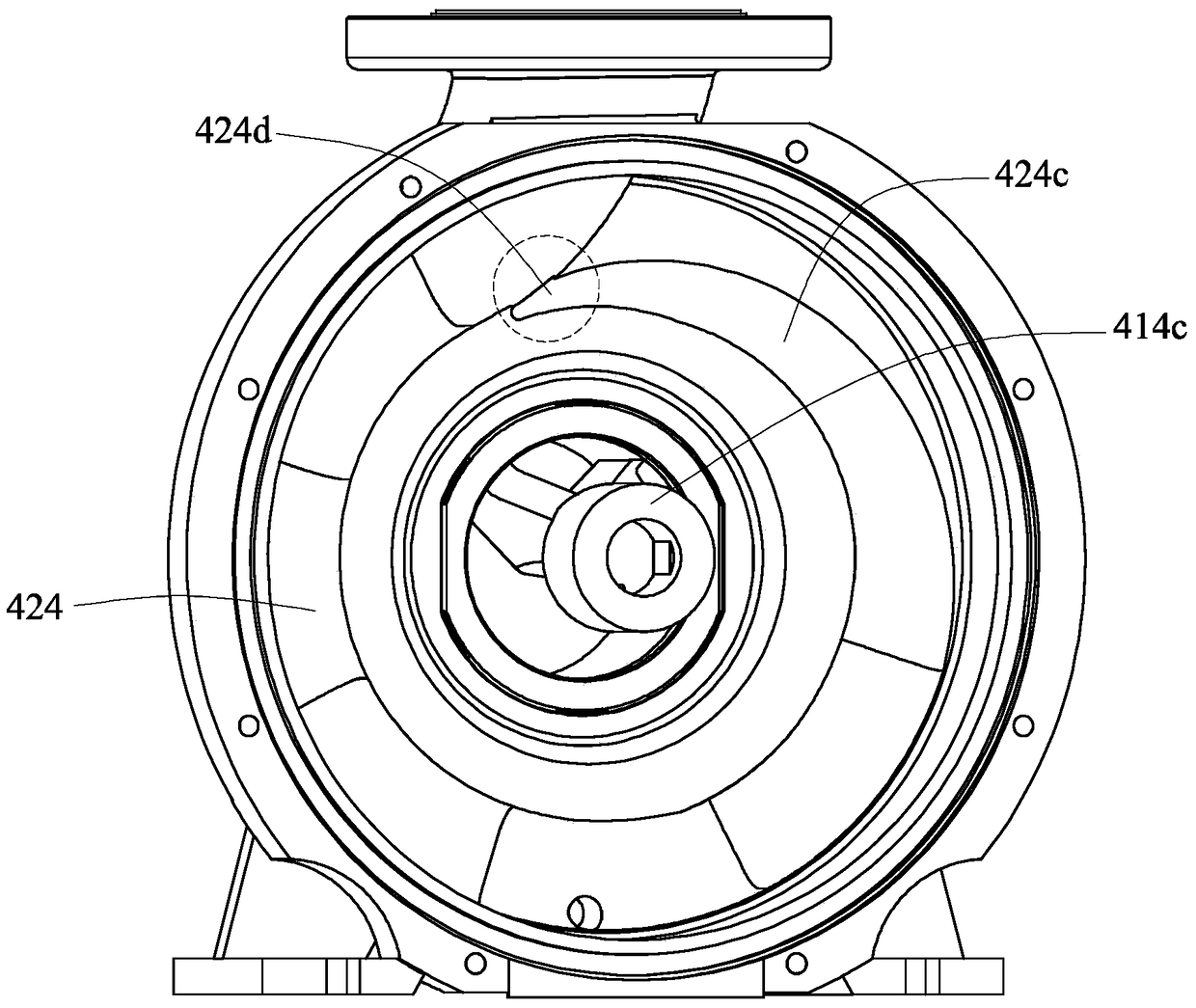

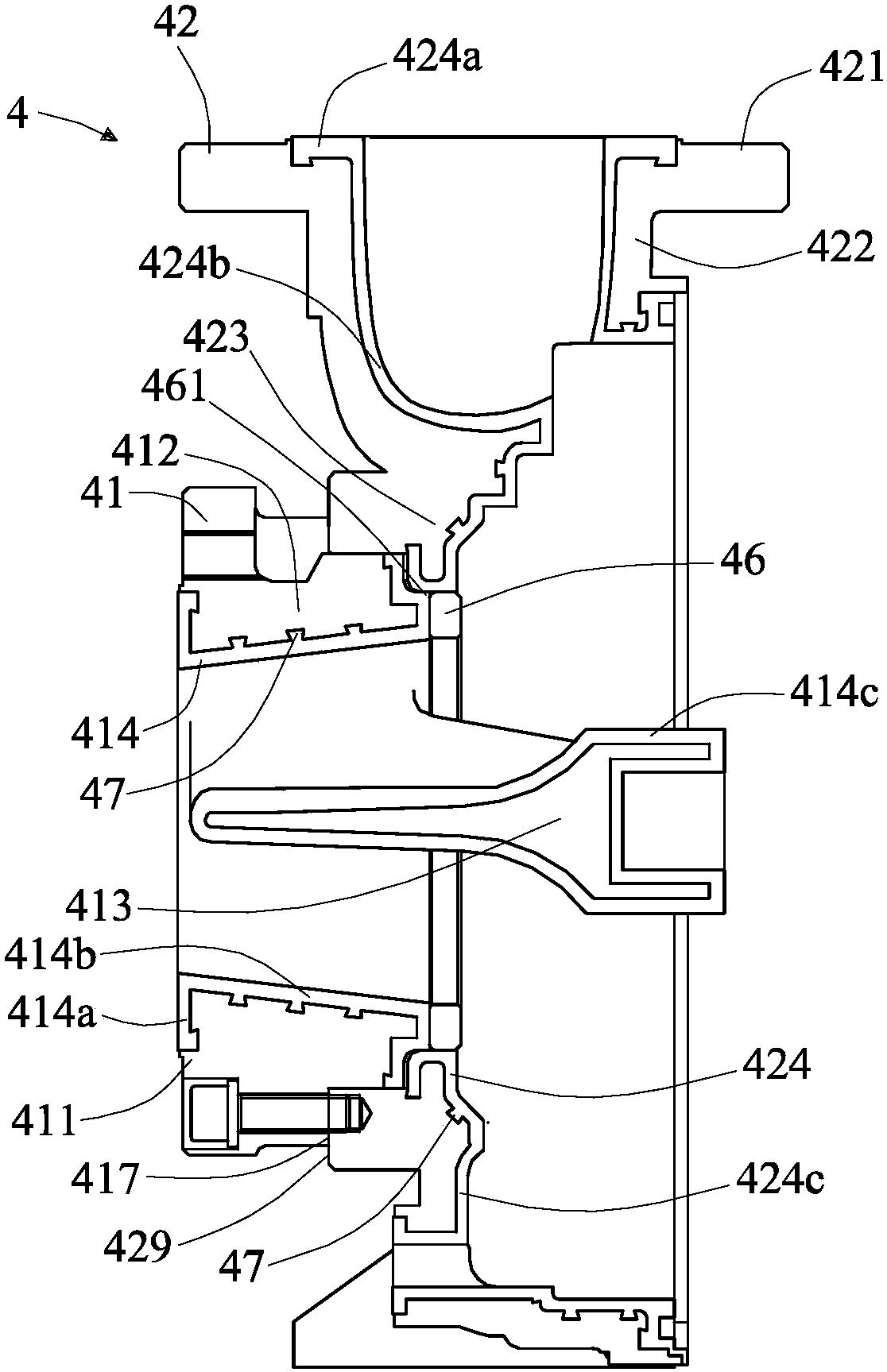

[0085] refer to figure 2 , Fig. 4(B), Fig. 5(A) and Fig. 5(B), the metal-lined PFA pump casing 4 of the present embodiment is a fixed shaft structure supported by both sides, and the main parts include: inlet casing 41 and scroll casing 42, wherein: the inlet casing 41 is cast iron or stainless steel lined with PFA, and is provided with an inlet flange 411, an inlet flow channel 412, a shaft support frame 413 and an inlet PFA lining 414, and several dovetail grooves are arranged inside the inlet flow channel 412 47. The inlet PFA lining 414 is covered with plastic by injection molding, including the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com