Sealed type polishing and sanding room

A grinding room, sealed technology, used in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problems of inconvenient cleaning, high fan power, affecting the surrounding environment, etc., and achieve the cost of use and maintenance. Low cost, lower maintenance costs, and comfortable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

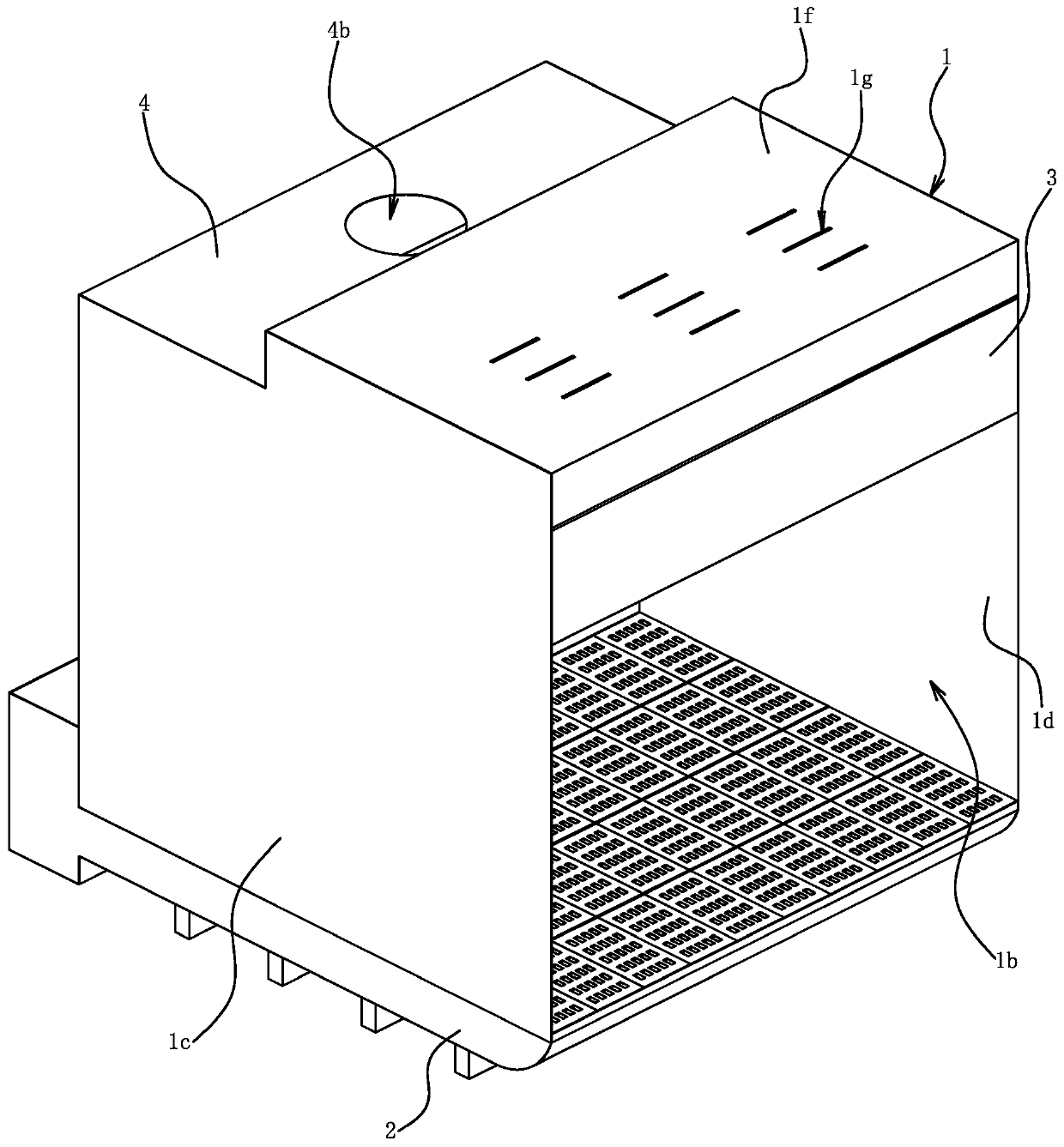

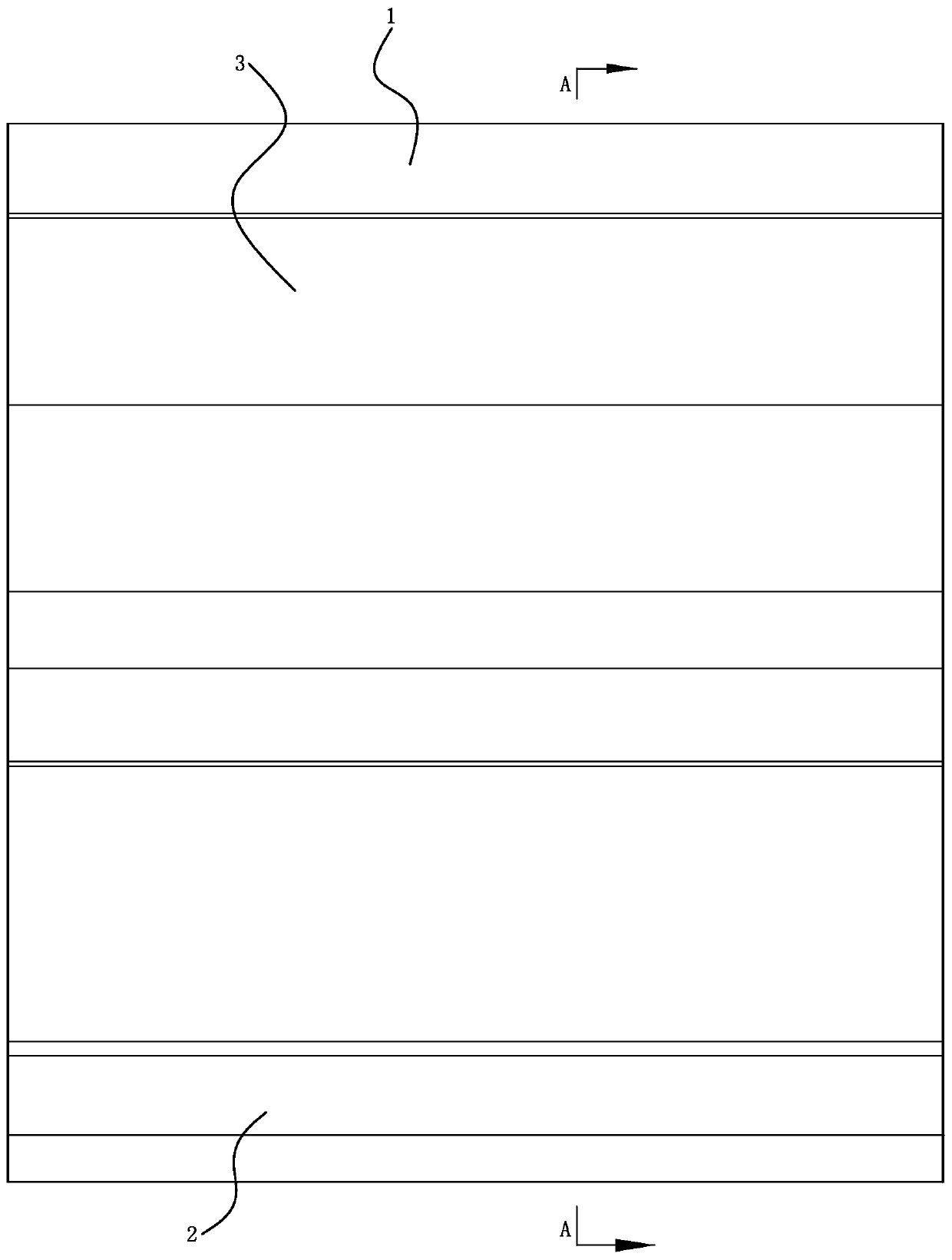

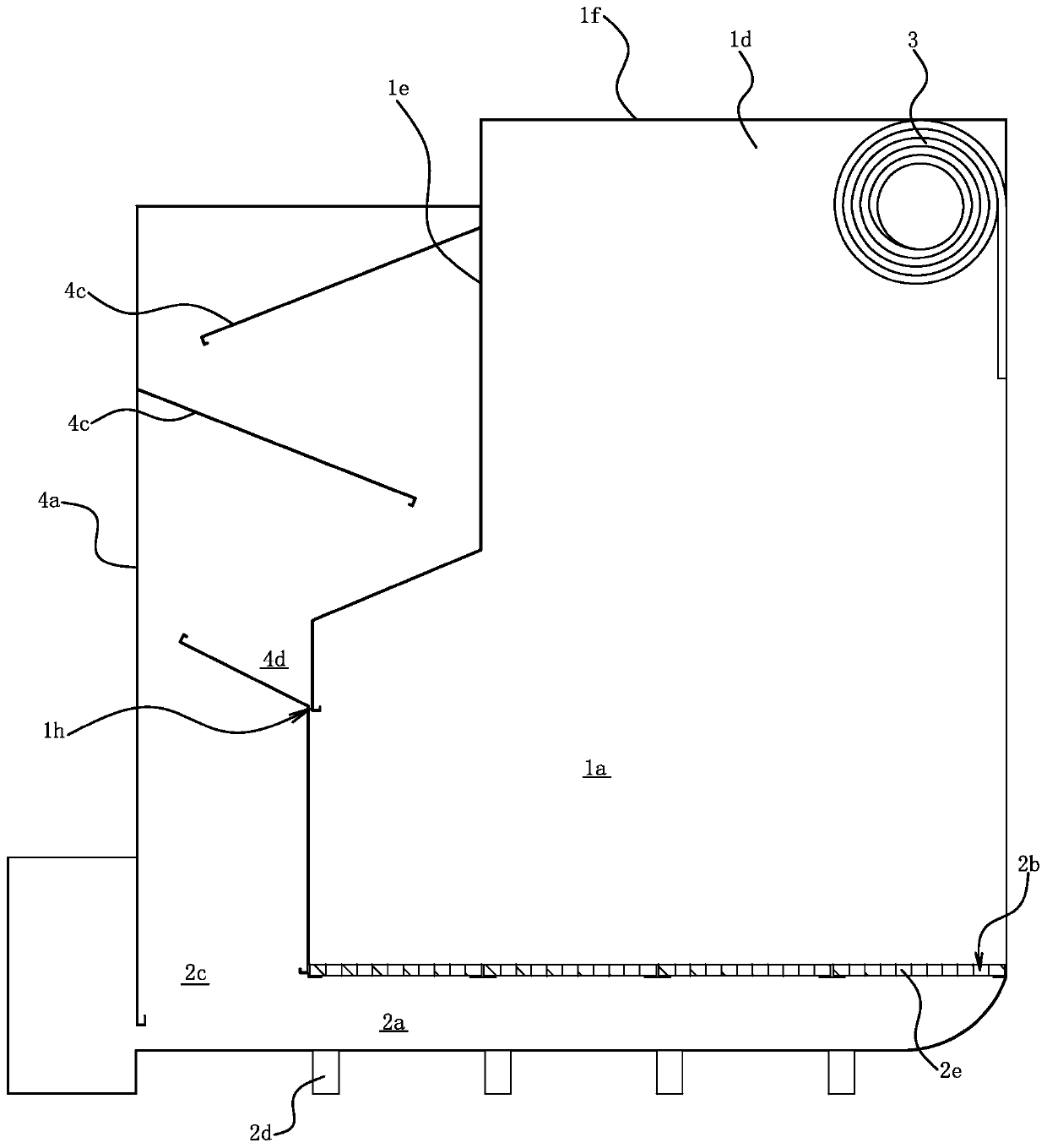

[0025] Embodiment one: if Figure 1 to Figure 3 As shown, the sealed polishing room includes a polishing room body 1 , a base 2 , an access door 3 and a separation unit 4 .

[0026] The grinding room body 1 has a grinding chamber 1a, the front side of the grinding chamber 1a is an entrance and exit 1b, and the grinding room body 1 includes a left side wall 1c, a right side wall 1d, a rear side wall 1e and a top plate 1f. There is an air inlet 1g in the top plate 1f. According to the actual situation, the air guide louver can be installed at the air inlet 1g, which can not only change the direction of the airflow, but also change the size of the airflow; the highest dust collection efficiency can be guaranteed by adjusting the direction of the airflow and the size of the airflow. .

[0027] The base 2 is placed on the ground, and the base 2 has a dust collection chamber 2a, and the top wall of the dust collection chamber 2a has a plurality of small dust inlets 2b for connectin...

Embodiment 2

[0035] Embodiment 2: The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described repeatedly, and only the differences will be described. The difference is that the separation unit 4 is dry separation, and the 4a is equipped with a filter element, and there is no need to set a water storage tank 4d in the casing 4a and no need to hold water in the dust collection chamber 2a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com