Metamorphic grabbing mechanism with automatic adjustment function

A grasping mechanism and automatic adjustment technology, applied in conveyors, conveyor objects, gardening, etc., can solve the problems of short and narrow doors, narrow passages, difficult reconstruction, etc., and achieve the effect of increasing the moving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

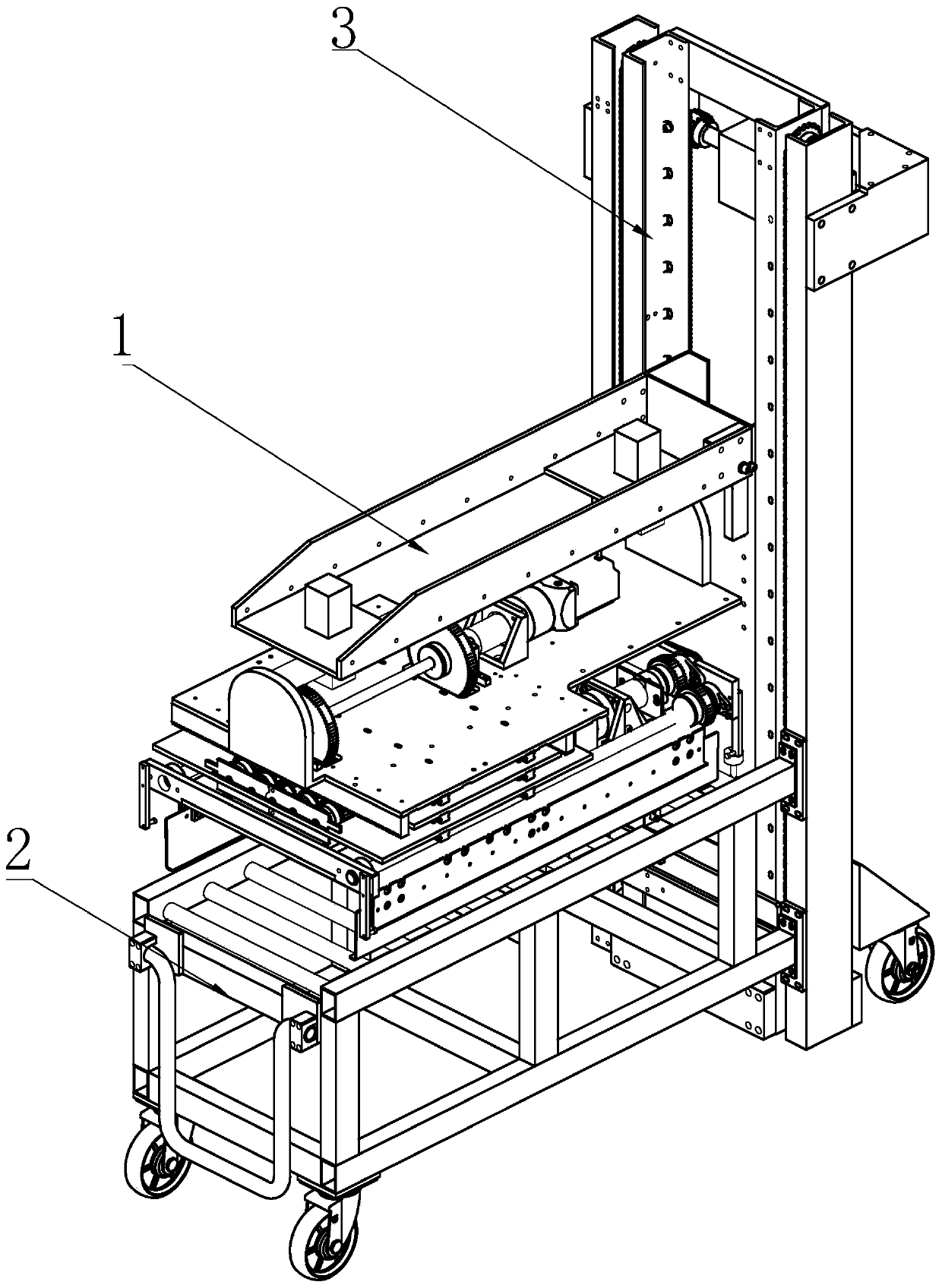

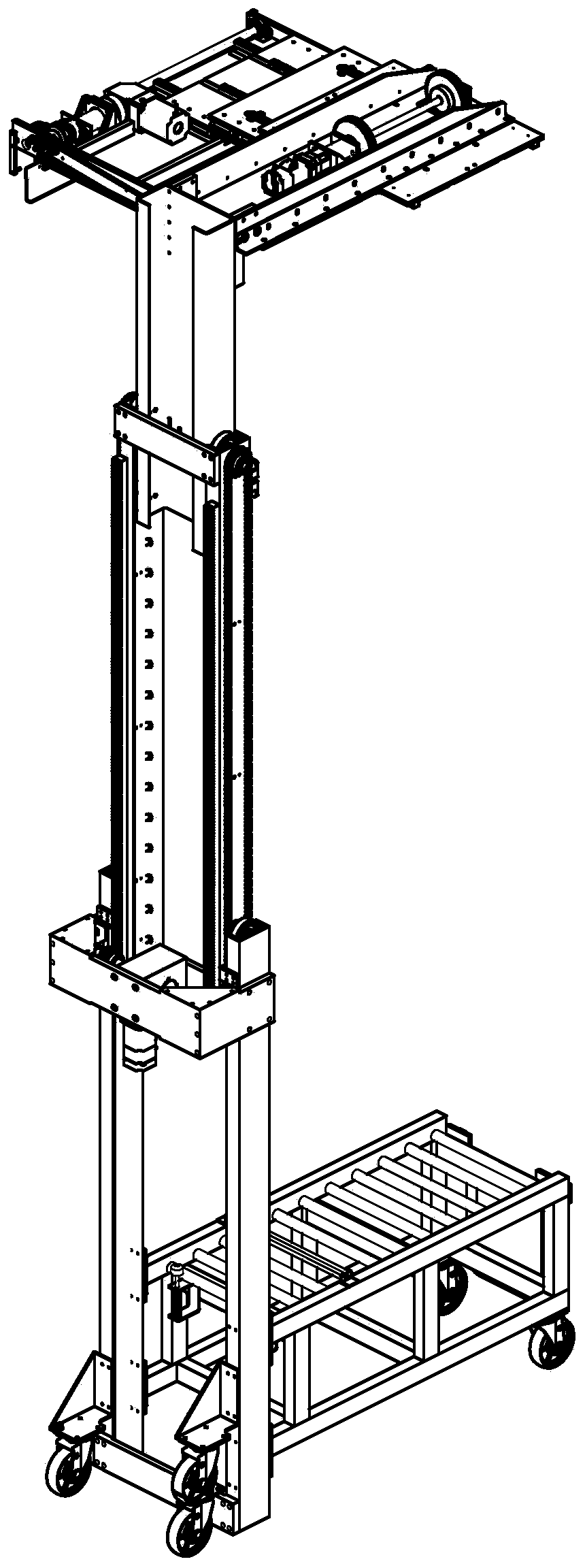

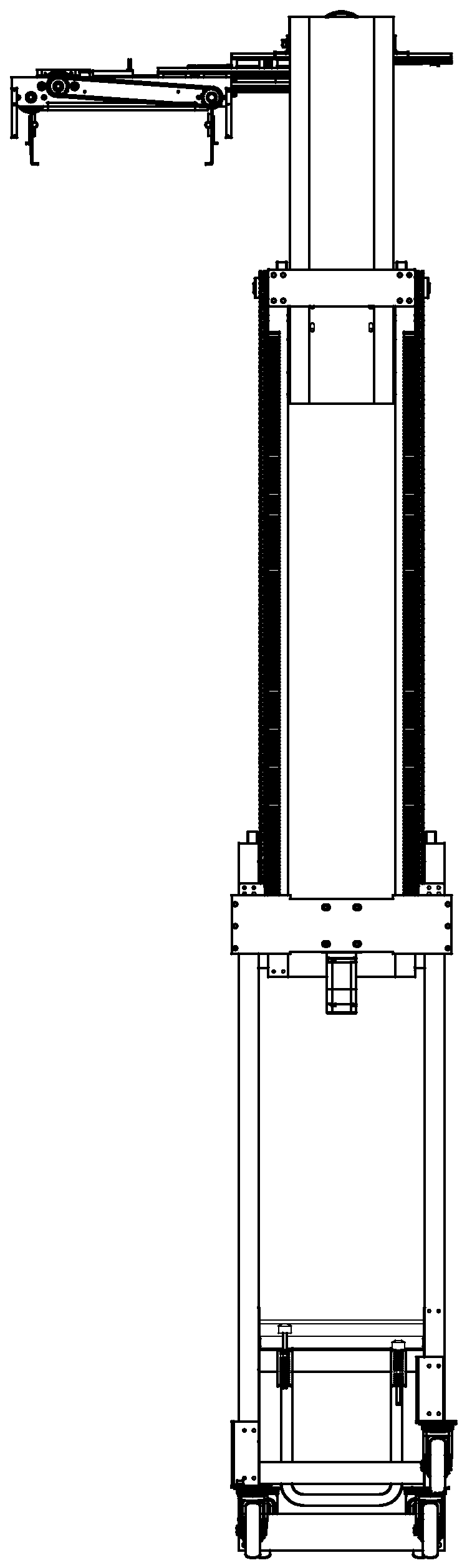

[0047] A metamorphic grasping mechanism with an automatic adjustment function, comprising a vertical support, an object stage, a lateral movement mechanism that moves laterally relative to the object stage, and a lifting device that drives the lateral movement mechanism to move up and down. One end of the object table is connected to the vertical support, and the lifting device moves up and down on the vertical support. The lateral movement mechanism is connected with the lifting device, and moves up and down following the lifting device. The vertical support and the loading table are provided with casters for easy walking. , On the traversing mechanism, there is also a metamorphic grasping mechanism that is arranged in pairs facing the stage for synchronous reverse rotation.

[0048] Such as figure 1 , the metamorphic grasping mechanism with automatic adjustment function includes 1 traverse mechanism, 2 stage, 3 lifting device,

[0049] Such as Figure 4 , The traversing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com